Introduksion

I manma'gås-ñiha na motor siha manma cho'cho' gi i modernu na industria, ya i aplikasion-ñiha manma'gås-ñiha yan manma'gås-ñiha. Para u ma na’setbe i nisisidåt na “high-speed operation”, i manmacho’cho’cho’ debi di u ma na’siguru na ma na’siguru na ma na’menos i “ manmafa’tinas na “ manmafa’tinas na teknolohian manmafa’tinas para u ma na’menos i “mersion-ñiha gi i motor yan i “efficiency.” Gi i mas takhilo’ na teknolohian manmafa’tinas, i teknolohian laminasion gi i motor lags guaha bentaha-ña gi i takhilo’ na presisu, takhilo’ na efisiente yan takhilo’ na densidad na densidad, pues ha na’guaha mas takhilo’ na siña ma usa gi i motor siha ni’ manma’a’ñao. Este na tinige' ha na'siguru na u ma'estudia i teknolohian i laminasion motor gi i motor siha ni' manma'a'ñao yan i manma'a'ñao na bentaha siha.

kada na tiempo i teknolohian lata siha gi motor .

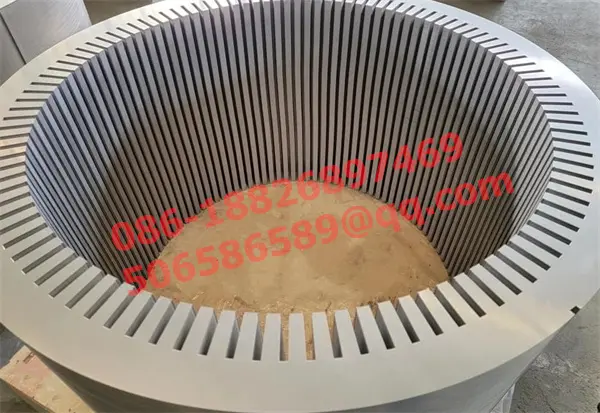

I teknolohian estao lags lag, un maneran fina'tinas ni' ha fotma un estao ni' ha na'daña' meggai na sheets gi un banda. Este na teknolohia ha na’siguru na guaha “high-precition” yan “laminate” na disision siha ni’ komplikao yan i nisisidåt siha ni’ siña ma na’setbe gi i toleransia. I teknolohian estao lator lag, ha na’guaha “high efficiency” na “power density” yan “high-precision motor” para i diferentes na aplikasion siha ni’ manma’a’ñao.

Aplikasion i teknolohian estao gi motor lator gi man-ma`gas na motor siha.

- Automote

Mas ke dos mit na taotao man-ma-usa gi karetan elektrisidat. I teknolohian estao lator lators, ha na'i i manma'titinas yan i manma'titinas, ya siña i manma'titinas, para u ma na'huyong i takhilo' na siñat yan i manma'gås-ñiha ni' manma'gås-ñiha gi i elektrisidåt. Este siña ha na’maolek i range yan i fina’tinas i vehikulo siha ni’ elektrisidåt.

- Atrospa

Gi i lugåt aerospace, guaha motor siha ni’ manma’usa gi i sisteman elektrisidåt yan drones. I teknolohian estao lator lag na teknolohia para u na’guaha takhilo’ na presisu yan efisiente na nisisidåt para i takhilo’ na operasion, u na’menos i fina’tinas yan i efisiente na aircraft yan drones.

- Industrial na automal

I man-ma`gas na motor siha man-ma`gas gi un` impottante na rol gi automamasion. I teknolohian estao lator lags ha na’guaha takhilo’, presisu yan fiet na mo’na na mo’na para u na’siguru na i manma’gås-ñiha gi i operasion i sisteman automation.

- Media

Gi i ekipon mediku, i “high-sped motors” ma usa gi i “devices” yan sisteman “drawing” gi mediku na ekipo siha. I teknolohian estao lator lators ni’ man-ma-elihe para u fan ma-ayuda gi che’chu’ niha para u fan ma-ayuda gi man-ma-elihe na operasion mediku siha.

I manma'å'ñao yan i Chalan siha

I “ekhiner stator” na teknolohian lag na teknolohia, meggai na bentaha gi i “high-speed motors,” taiguihi i takhilo’ na presisu, takhilo’ na efisiente yan takhilo’ na densidad i fuetsa. Lao, este na teknolohiha lokkue’ ha na’fanhuyong dididi’ na chinathinasso, put hemplo, i gaston manmafa’tinas, komplikao yan konfi’ansa. I man-ma-ayuda na taotao siha debi u fan ma-ayuda este siha na chinatsaga para u fan ma-ayuda gi ma-adelantan inadotna gi teknolohian estarinan motor.

Pot uttimo

I inestudia siha ha fa’nu’i na i teknolohian estao lator guaha impottånte na balotu gi i aplikasion gi alacha na motor siha, ni’ siña ha na’menos i fina’tinas yan i efisiente na motor siha, ti åpmam na tiempo, yan i lina’la’ i taotao siha gi i prudukto. Lao, i teknolohia lokkue’ ha na’fanmanman i taotao siha ya ha nisisita mas inestudia yan desarollo. I mamaila' na cho'cho' debi di u na'fotma i asunton sobriha taiguihi i manmafa'tinas na salåpe', i komplikao na prugråma, yan i siña ma'usa para u na'guaha i mas takhilo' na aplikasion i teknolohian lakus gi i motmot gi i teknolohian motmot gi i mas takhilo' na motor siha.

På'go na Teknok

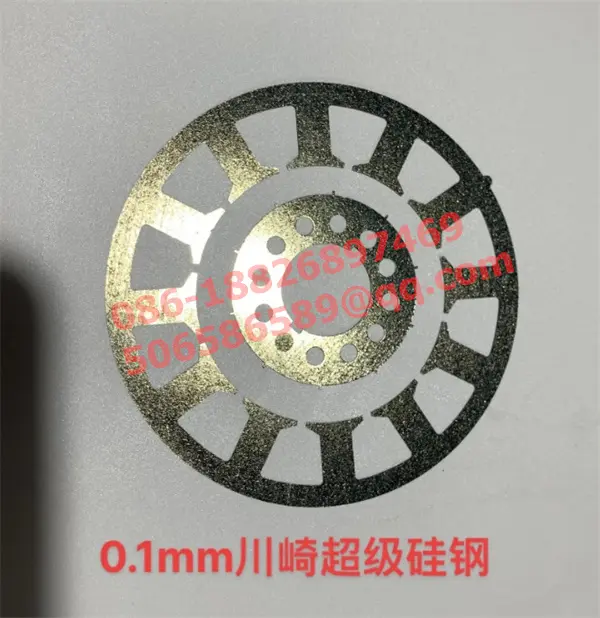

You Technology Co., si Ltd. ha espesiålisa gi i fina'tinas i hånom tåsi ni' ma fa'tinas ginen diferentes na gå'ga' siha ni' manma'gåsi, kontodu silikon silicon, kontodu silikon silicon, yan i steel-thin steel-thin steel-thin, yan i manma'gås-ñiha na alloys ni' manma'gås-ñiha. Ma u'usa i manma'gås-ta na prugråman manmafa'tinas para i presisu na kosas siha, ya ma na'i solusion siha ni' manma'gås-ñiha para i båba na nuebu na magnetic na kosas siha ni' ma'usa gi i mas takhilo' na lugåt siha taiguihi i takhilo' na gå'ga' siha, i motor siha ni' manma'gås-ñiha, i manma'gås-ñiha, i manma'gås-ñiha, yan i manma'gås-ñiha.

I kompaniha ni' para u fanma'gåsi i prudukto siha ni' manma'gås-ñiha på'go na tiempo, ma na'halom un rangkon silicon gi 0.05mm (ST5mm(ST-050), 0.10mm (10JNEX900/ST ST00-100, 0.15mm, 0.2mm (20JEHHHH100/200/200. 235SIN2100