I estamping stamping na prugråma ni' para u na'fanhuyong i taotao siha, unu gi i mas impottånte na siña maayek para u na'siguru na i estao-ña.

I estamping stamping na prugråma ni' para u na'fanhuyong i taotao siha, unu gi i mas impottånte na siña maayek para u na'siguru na i estao-ña.

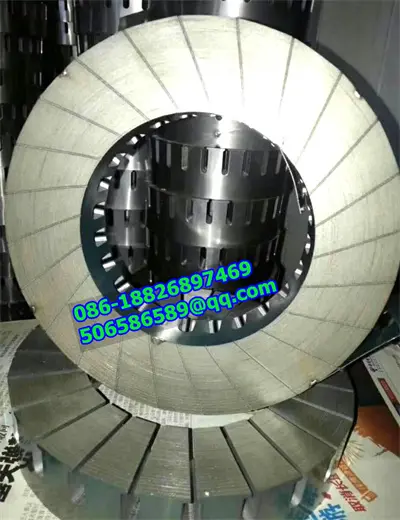

Primet, diseha i estao na core sigun i rekisitos disision yan i nisisidåt siha para i fina’tinas i motor. Este ha na'halom i parametru siha taiguihi i fina'tinas, i mineggai, i tipo' yan i numeron slot siha.

Na'i i stamping molk siha sigun ginen i dibuhon diniseño gi i nuebu na estao. I sello matai, kulan konsiste gi un’ upper esta måtai ya mas takhilo’ i finatai-ña ya ma usa para u ma usa gi i silicon na silicon sheets gi i forma ni’ i estator core.

Selekta na magnetic na materiåt siha, taiguihi i silicon sheets, komo i materiåt siha ni’ manma’a’ñao para i estao-ñiha. Ha bira siha tatte gi silulion na asero gi propiu na simetbe para u mapo’lo gi sello siha manmatai pot estampa.

Put i plåton asero gi i hånom tåsi, yan gi i presion i molde siha gi sanhilo’ yan mas takhilo’ na molde, i silicle steel plate na steel steel ma’ampli’e’ sigun ginen i forma ni’ i molde. Gi duranten i prugråman sello, i siyan asero na steel sheet ma gof åpmam, ma na’setbe yan ma fotma gi i grooves gi i core core.

Despues di ma kumple i sello siha, i nuebu na “scorator” na “core core” para u ma inspekta para u na’siguru na i “size”-ña, i “chan” konforma gi i nisisidåt i disision. Yanggen guaha deviations, inadåpta pat inadåpta siha debi di u ma cho’gue.

Gi i mas takhilo', i stampetor stamp unu gi i mas impottånte na pas gi i fina'tinas i estao-ña gi un motor flux. Ha nisisita i konsiderasion put i materiåt siha put i materiåt, disision yan pruduksion, dimension na eksakto yan otro na faktores, ya guaha siha na difirensia gi i teknolohiha.

You Technology Co., si Ltd. ha espesiålisa gi i fina'tinas i hånom tåsi ni' ma fa'tinas ginen diferentes na gå'ga' siha ni' manma'gåsi, kontodu silikon silicon, kontodu silikon silicon, yan i steel-thin steel-thin steel-thin, yan i manma'gås-ñiha na alloys ni' manma'gås-ñiha. Ma u'usa i manma'gås-ta na prugråman manmafa'tinas para i presisu na kosas siha, ya ma na'i solusion siha ni' manma'gås-ñiha para i båba na nuebu na magnetic na kosas siha ni' ma'usa gi i mas takhilo' na lugåt siha taiguihi i takhilo' na gå'ga' siha, i motor siha ni' manma'gås-ñiha, i manma'gås-ñiha, i manma'gås-ñiha, yan i manma'gås-ñiha.

I kompaniha ni' para u fanma'gåsi i prudukto siha ni' manma'gås-ñiha på'go na tiempo, ma na'halom un rangkon silicon gi 0.05mm (ST5mm(ST-050), 0.10mm (10JNEX900/ST ST00-100, 0.15mm, 0.2mm (20JEHHHH100/200/200. 235SIN2100

As an stator and rotor lamination bonding stack manufacturer in China, we strictly inspect the raw materials used to make the laminations.

Technicians use measuring tools such as calipers, micrometers, and meters to verify the dimensions of the laminated stack.

Visual inspections are performed to detect any surface defects, scratches, dents, or other imperfections that may affect the performance or appearance of the laminated stack.

Because disc motor lamination stacks are usually made of magnetic materials such as steel, it is critical to test magnetic properties such as permeability, coercivity, and saturation magnetization.

I ma'pos na bånda, un fundamental na kosas gi i motor elektriku ya ha cho'gue un rol klaru put i konbetsion i enerhian elektrisidåt gi i mekaniku na enerhian mekaniku. Essentiatmente, ha konsiste este na colas ni’, yanggen manma’a’ñao, ha na’fanhuyong un “rotatic field” ni’ ha na’fanma’a’ñao i motor. I presisu yan i kualidåt i estådu na bånda siha direktamente ha afekta i efisiente, torque, yan gi enteru i motor. Manma ofrese un komprendiyon na rangkon setbisio siha ni’ para u na’siguru na guaha meggai na klasin motor yan aplikasion siha. Yanggen un sodda’ solusion para un dikike’ na prohektos pat un dangkolo na motor industria, i eksperensia-ta ha garantiyi i mas maolek na cho’cho’ yan i lina’la’.

I man-epoxy powder cocky technology ha na’fan-ma’a’ñao i taotao siha ni’ man-ma’a’ñao na u fanma’a’ñao gi un’ banda para u fanma’a’ñao gi un’ solidu na proteksion. asegura na i motor i core mas takhilo’ na resistensia gi i korona, i desgaste yan i “environmental” na faktores. Gi i ma'pos na tiempo, i epoxed powder powder ha na'maolek i thermal efficiency gi i motor, ya ha na'siguru na ti maolek i lina'la'-ña gi i tiempon operasion.Ma'estra ha' este na teknolohiha para u na'i i top-notch na xy xy powder setbisio siha para i nuebu na motor siha. I estao-ta-ta-ta-ta, kombinidu-ta yan i eksperensian-ta gi i ekipo-ta, ha na’siguru na guaha perfekto na aplikasion, ha na’menos i lina’la’ yan i fina’tinas i motor.

I manma'a'a'ñao na taotao siha para u ma na'huyong un insulasion ni' ma na'i i insulation na lugåt para u ma na'setbe i stator siha. Este na teknolohiha ha na'fanhuyong un thermosetting resina, ni' ma na'setbe para u na'fanhuyong un solidu na inadahin pdtgun yan i prugråman diyeksion diyeksion para i fina'tinas yan i uniforme na kontodu i siña maayek na lugåt siha ni' para u na'siguru na guaha siña ma cho'gue para u na'siguru na guaha siña ma cho'gue para u na'siguru na guaha inafekta gi i lina'la'-ñiha gi i sagan-ñiha. i mas maolek na inayek elektrisidåt. I capa ni’ insulasion ha prebeniyi sirrrr siha ni’ manma’ayek, ha na’menos i lina’la’ i taotao siha, ya ha na’menos i enteru na cho’cho’ yan i siña maayek na estao i motor.

Gi i aplikasion motor ni' gof åpmam, i laminasion i nuebu na estao siña ma'usa para u fanma'gåsi. Para u makombida este na problema, i ma'pos na tiempo, gof impottånte. Este na prugråma ha aplika un prutehi na lay ni' guaha 0.01mm asta 0.025mm asta i laminate.Gi i laminate.Gi i tiningo'-ta gi i proteksion i estao para u na'guaha i mas maolek na inafekta gi i disision-mu.

I dikike' na steel na asero siha gi i hånom, guaha 0.05/0.10/0.15/0.20/0.35/0.35.5MM yan otro siha. Ginen dangkulon lalos gi halom Japon yan iya China. Guaha siha silicon gi asero yan 0.065 na silicon gi alacha. Guaha bahu na silikon silicon ni' manma'å'ñao yan manma'å'ñao. I grådu siha gi stock manriku yan todu i siña ma cho’gue.

Adimas di stamping yan laser curting, ecotching wire, forming forms, powder metallorgy yan otro na prosesu siha siña lokkue’ ma usa. I sekundaria na prugråma siha gi i laminasion motor siha, ma na’guaha glue, electrophopasesis, insulasion, ma na’setbe, ma na’setbe, yan otro siha.

Siña un na'hanao i infotmasion-mu, taiguihi i dibuho siha put disision, materiåt, yan otro siha, gi i email. Puedi ta fa’tinas i otden para i motor-ta maseha hafa na dañkulu pat dikike’, achokka’ 1 piesa.

I laminate-ta siha gi motor-ta manmafa’sahnge gi meggai na faktores, kontodu i simetbe yan i komplikao. Tipå-ña, i propetision-ta siha ni’ manma’gås-ta gi i laminasion 7-20 dihas. I tiempon fina'tinas i tataotao para i rotor yan i estao na pilan siha 6 asta 8 simana pat mas tiempo.

Hunggan, manma'ofresi ham OEM yan setbisio ODM. Guaha mas eksperensia-ta gi intendimienton motor core.

I konsepton rotor ha na'setbe i bond, kumeke'ilekña na u ma'usa un prugråman rollo ni' ma'a'agang "insulating ageding agent" gi i sheets gi i motor despues di ma'a'atan pat ma'a'atan i laser. I laminasion siha manmapo’lo gi un estacking fihu gi papa’ presion ya manma’a’ñao gi segundu biahi para u ma kumple i siklon cuer. I tataotao ha na'suha i nisisidåt para i rivet na inafekta siha pat para u na'lå'la' i magnetic core, ni' ha na'menos i pineddong interlaminar. I bonded cores ha na’fanhuyong mas maolek na kondukta, ni’ håfa na ruido, yan ti ha na’fanhuyong i temperatura.

Taimanu. I teknolohian glue ni’ in’ usa para in’ na’i hamyo ni’ man-ma’gas. I adhesive ni’ ta usa i heat resistensia yan ta mantieni integridat achokka’ gi ekstremo na kondision i temperatura, ni’ ha na’fanmagof hit para i aplikasion siha ni’ manma’gås-ta gi high-performance motor.

Glue dold bonding ha na’fanhuyong i man-ma’a’ñao na glue gi laminates, ni’ man-ma’a’ñao gi papa’ presion yan guafi. Este na manera ha na’guaha un bond presisu yan uniforme, asegura na optimal na fina’tinas-ña.

Self-bond ha referi i inetnon i matiriåt ni’ para u na’guaha gi i laminate mismo, ya ha na’fanhuyong i bonding para u ma na’setbe gi i tiempon-ñiha sin i nisisidåt para u na’guaha mas adhesives. Este na siña ha na’fan-ma’gas i lina’la’-ta.

Hunggan, i manma’a’ñao na taotao siha siña ma usa para u ma segmenta na estao, yan presisu na bondsing gi entre i segmento siha para u ma na’huyong un asembly assembly ni’ ti ma na’setbe. Ti guaha eksperensia-ku gi este na areklamento. Man-ma`ug i man-ma`gas gi setbisiun kustomer.

Kao guaha un` fiet na estao yan fiet na Self-adhesives ni man-ma-espiha gi iya Manufacture ginen China? Li'e' na ti un li'e' na Fanå'gue ham på'go na tiempo para i solusion yan i estao i estao-mu ni' siña ha na'setbe i espesifik-mu.

Kontaktu i gurupon tekniku-ta på’go para un na’siguru na guaha solusion na silicon gi i mismo na lugåt siha ya un tutuhon i biahi-mu gi i innovation gi i motor ni’ manma’a’ñao!

Get Started NowRekomendasion para i