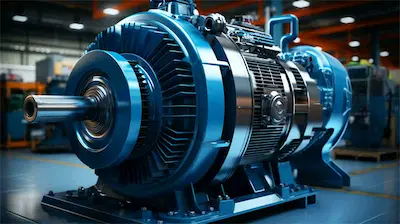

Axial flux motors are extremely efficient motors. As a leading manufacturer in China, our company excels in precision manufacturing of custom axial flux stator laminations. In addition, we can produce custom high-speed and high-efficiency motors. Whether you need a large motor, a small motor, or segmented stator laminations, we can meet your needs.

We can customize stamping dies to produce high-quality disc motor cores to your specifications. In addition, we also provide comprehensive stator winding services. The versatility of our manufacturing processes makes us a reliable partner for your unique requirements.

Customize Axial Flux Stator Lamination Stacks

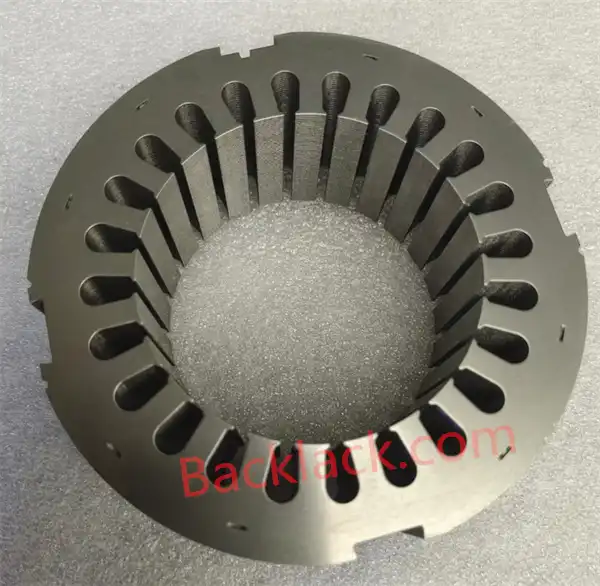

We offer custom axial flux motor stator cores for electric motors and generators, both for traditional axial flux stator designs with electrical steel laminations, and for cutting-edge soft magnetic composite axial motor stators, amorphous axial flux stator cores, and skewed disc motor stators.

Whether you need a large motor, a small motor, a segmented stator lamination, or a custom high-speed and high-efficiency motor, our expertise guarantees that the exacting needs of your project are met. The motor cores are carefully designed to provide optimal performance and reliability in a variety of applications.

Our custom axial flux stator solutions meet a variety of application needs, including electric vehicles, new energy commercial vehicles, new energy passenger vehicles, automotive hubs, wind turbines, robotics, industrial machinery, and aerospace systems.

Compared to traditional radial motors, our axial stator cores have higher efficiency and power density, facilitating more compact designs and higher performance in a variety of applications.

In addition, we also customize stators for appliance motors, power tool motors, pump motors, elevator traction motors, rail transit motors, direct drive appliance motors, drone motors, electric vehicle motor applications, etc.

Materials Of Axial Flux Motor Stators

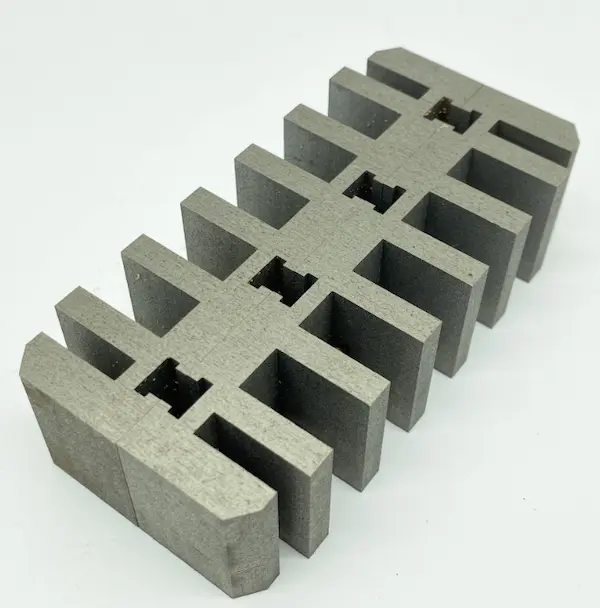

For axial flux motor stators, three main materials are usually used: silicon steel sheets, amorphous alloys and Soft Magnetic Composite(SMC) materials.

Silicon steel sheets are well known for their excellent magnetic properties and are usually used for their high magnetic permeability and low iron loss, making them ideal for effectively guiding the magnetic flux in the stator.

Amorphous alloy materials can completely replace silicon steel sheets. Amorphous materials can reduce the core loss of the motor by 0.80-0.93, and their high-frequency iron loss is 1/8-1/10 of that of silicon steel sheets, reducing the temperature rise of the motor and increasing the efficiency by 0.03~0.10.

Soft Magnetic Composite(SMC) materials have high magnetic permeability and low coercivity, and can be quickly magnetized and demagnetized under the action of alternating current. Through powder metallurgy processing, secondary processing such as punching, grinding, drilling, etc. can be greatly reduced.

Design And Manufacture Capabilities For Axial Flux Motor Core Laminations

Materials Procurement Expertise

YOUYOU company specializes in sourcing and providing expertise in various types of electrical steels including Non-Grain Oriented (NGO), Grain Oriented (GO) and Cold Rolled Motor Laminated (CRML) steels. Silicon steel materials are available in laminate thicknesses ranging from 0.05mm to 0.65mm.

Advanced Stamping Capabilities

We have extensive capabilities in advanced stamping processes, including progressive stamping, large blank compound stamping, and rotary groove stamping. Our global reach and capabilities meet a variety of production needs, demonstrating manufacturing versatility.

Enhanced Motor Performance and Quality

We specialize in providing precision lamination solutions designed to improve motor performance and reduce core losses, thereby increasing overall motor efficiency. We are committed to helping customers achieve cost savings in the manufacturing process.

On-time, Complete Delivery

High-volume production facilities are designed for quality and efficiency, ensuring timely and complete delivery of customer orders. Reliably meet production schedules and maintain consistent order fulfillment.

Provide Technical Support

Our professional design and engineering teams can work with customers throughout the product development process. From conception to manufacturing, we always strive to be a trusted partner in product design and development.

Other Related Premium Services

YOUYOU company offers a range of value-added services beyond basic lamination manufacturing, including annealing, bonding, welding, riveting, splinting, shaft plugging, insulation coating, wire winding, die casting, deburring, wire cutting and laser cutting.

OUR SERVICES

Manufacturing Process Of Axial Flux Stators

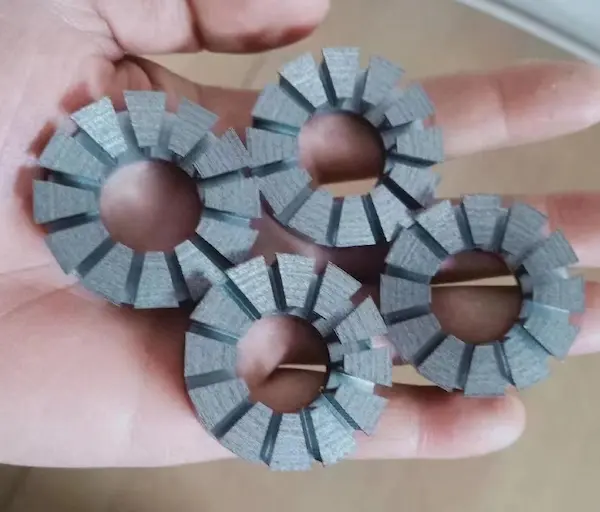

The Axial Flux Stator adopts special stamping and winding equipment, and the slot shape is stamped by special stamping die. The servo synchronous control system is used to accurately control the stamping frequency and winding speed to achieve consistent alignment of the product from the inner diameter to the outer diameter.

Silicon steel sheets are the key material for producing high-performance axial flux stator cores. We also use more advanced self-bonding lamination technology, and adhesive bonding can ensure optimal alignment, further reducing eddy current losses and improving electromagnetic efficiency.

We have been committed to the research and development of Axial Flux Stators production process for many years. We have a complete Axial Flux Stators production line and provide one-stop solutions for Axial Flux Stators, including stamping, winding, drilling, bonding, welding, annealing, winding, etc.

OUR SERVICES

Axial Flux Stators Winding Process

Axial flux stator winding involves finely winding coils in a direction parallel to the rotor axis. This unique configuration optimizes the flux path, increasing power density and overall motor efficiency.

In the axial flux stator winding process, the coils are precisely wound around the stator's laminated core, ensuring a compact and efficient design. The winding arrangement facilitates a short magnetic path, reduces energy losses and improves the motor's power-to-weight ratio.

This winding technique is particularly beneficial in applications where space and weight constraints are critical, such as electric vehicles and aerospace systems.

As a leader in axial flux technology, youyou specializes in providing high-quality stator winding solutions to improve the performance of electric motors in various industries.

Quality Control for Axial Flux Stators

As an axial flux motor stator lamination manufacturer in China, we strictly inspect the raw materials used to make the laminations.

Technicians use measuring tools such as calipers, micrometers, and meters to verify the dimensions of the laminated stack.

Visual inspections are performed to detect any surface defects, scratches, dents, or other imperfections that may affect the performance or appearance of the laminated stack.

Because disc motor lamination stacks are usually made of magnetic materials such as steel, it is critical to test magnetic properties such as permeability, coercivity, and saturation magnetization.

Other Stacking Techniques For Electrical Steel Lamination Stacks

Riveting

Riveting uses mechanical fasteners to hold the laminations together. This method is reliable and easy to implement but can add weight and create stress points within the stack.

Laser Welding

This technique uses a high-powered laser to weld the laminations together at specific points. Laser welding provides a strong bond and precise alignment but can introduce localized heating.

Interlocking

Interlocking involves creating tabs and slots on the edges of the laminations, allowing them to snap together without the need for additional bonding agents.

FAQS

How do axial flux stator laminations differ from traditional stator laminations?

Traditional stator laminations in radial flux motors differ from stator laminations in axial flux motors. Axial flux motor stator laminations allow the flux to flow parallel to the motor's axis of rotation, rather than perpendicularly. This design allows for a more compact and lightweight motor construction.

What are the advantages of using an axial flux motor stator core?

Axial stator cores offer several advantages over traditional radial flux motors. These advantages include higher power density, higher efficiency, and enhanced heat dissipation. Axial stator cores excel in these areas compared to radial flux motors. Additionally, axial flux motors can offer a more compact design, making them suitable for applications where space is limited.

How does an axial flux stator affect the overall performance of an axial flux motor?

The production of axial flux motor stator core laminations affects all aspects of motor performance, including efficiency, torque output, and operating temperature. Their design and quality directly affect the electromagnetic characteristics of the motor, resulting in improved power output, reduced losses, and increased reliability.

Can axial flux motor stators be customized for specific applications?

Yes, we often offer customization options to tailor stator designs to meet the specific requirements of different applications. This may involve optimizing parameters such as number of stator slots, winding configuration, and magnetic material properties.

What is the purpose of an axial flux motor stator core?

The axial flux motor stator core provides a magnetic path for the magnetic flux generated by the rotor, helping to convert electrical energy into mechanical motion. It supports the winding coils and affects the overall efficiency and performance of the motor.

What factors affect the performance of an axial flux motor stator core?

Key performance factors include material quality, lamination thickness, and the precision of the manufacturing process. In addition, proper alignment and insulation of the laminations affect the efficiency and reliability of the stator core.

Looking for Axial Flux Motor Stator Laminations Manufacturer from China?

Looking for a reliable Axial Flux Motor Stator Laminations Manufacturer from China? Look no further! Contact us today for cutting-edge solutions and quality stator laminations that meet your specifications.

With our expertise, advanced technology, and commitment to excellence, we ensure that every product has the best performance and durability.

Contact us today for a seamless experience and learn why we are your preferred disc motor stator laminations manufacturer from China. Your satisfaction is the driving force of our work!

Recommended For You