In modern industry, motors and generators are indispensable equipment, providing continuous power and electrical energy for our lives. However, to achieve greater energy efficiency and reliability, manufacturing the stator laminations for these devices requires precise machining and assembly. In this regard, laser cutting of stator laminations represents a key innovation.

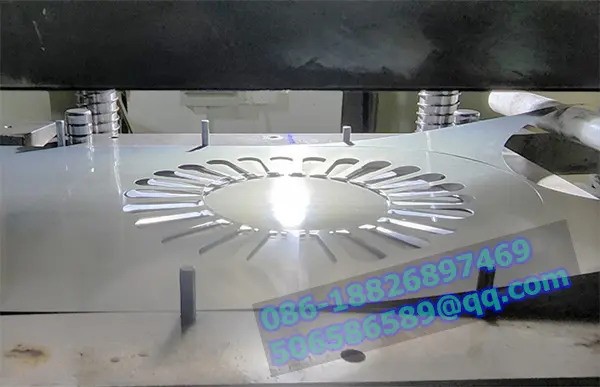

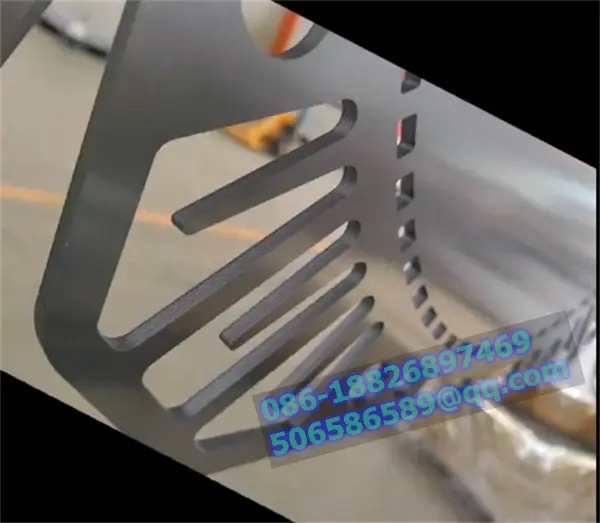

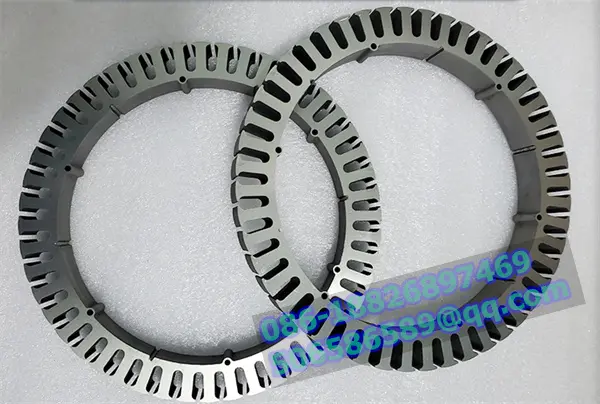

Laser cutting of stator laminations is an efficient processing method by directing a laser beam to cut through thin metal sheets to obtain the desired shape and size. The accuracy of this cutting method ensures that the laminations fit together perfectly, reducing energy loss. Laser cutting of stator laminations offers many advantages over traditional machining methods.

First, with the help of advanced software and automation technology, laser cutting stator laminations can quickly and accurately cut the required shape, minimizing material waste. This not only improves production efficiency but also reduces manufacturing costs. Second, laser cutting the stator laminations ensures that each lamination has the same laminate structure and meets the required specifications. This makes the stator lamination manufacturing process more reliable and consistent.

The application of laser cutting stator lamination technology is of great significance to the motor and generator industry. It not only improves the efficiency of energy conversion, but also enhances equipment reliability and performance. By reducing energy losses and gaps, laser-cut stator laminations provide a more stable and efficient solution for the energy conversion process of electric motors and generators.

In addition, laser-cut stator lamination technology is ideal for rapid prototyping of electric motors and generators. Its ability to easily customize and iterate designs gives manufacturers greater flexibility and room for innovation. This is critical to advancing electric motor and generator technology, giving us a more sustainable and environmentally friendly future.

In summary, laser-cut stator lamination technology is a key innovation in the electric motor and generator industry. It improves the efficiency of energy conversion and the reliability of equipment through efficient processing and assembly processes. As technology continues to develop, laser cutting stator laminations will continue to drive advancements in motor and generator technology, creating a greener and more sustainable energy future for us.