With the development of renewable energy technology, wind power generation has attracted widespread attention for its environmental protection and sustainability. As one of the key components of wind turbine generators, the axial flux stator lamination stacking process is the core of its efficient and stable operation. One of the technologies. This article will provide an in-depth analysis of the axial flux stator lamination stacking process used in wind turbine generators and its key technologies.

1. Overview of axial flux stator lamination stack

The axial flux stator lamination stack is an important structure inside the motor. It stacks multiple layers of thin silicon steel sheets through a precision lamination process to form a closed magnetic circuit to achieve effective conversion of electrical energy and mechanical energy. In wind turbine generators, this structure is particularly suitable for high-power, low-speed working environments, and can effectively improve motor efficiency and reduce losses.

2. Detailed explanation of process flow

2.1 Material selection

High-quality silicon steel sheets are selected as the basic material. It has good magnetic permeability and low loss characteristics, which is crucial for reducing iron losses during the operation of the turbine generator.

2.2 Lamination stamping

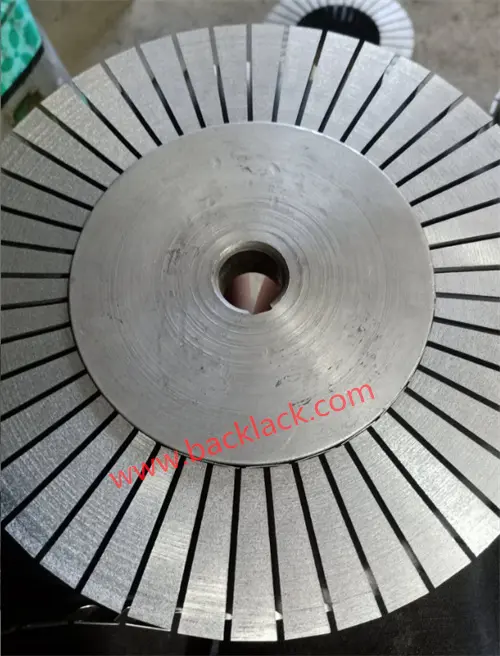

Precision molds are used for stamping processing to ensure that the size of each silicon steel sheet is accurate. At the same time, taking into account the eddy current effect, the silicon steel sheets will be grooved or beveled to reduce losses.

2.3 Stack assembly

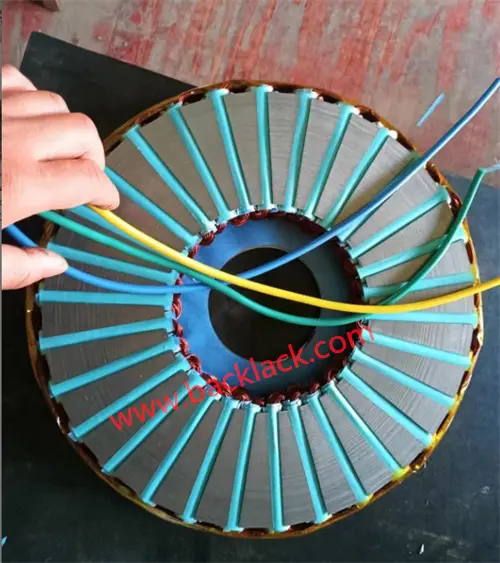

After insulation treatment, the silicon steel sheets are stacked closely and orderly in a specific order to form the stator core. During this process, it is necessary to ensure that a small gap is maintained between adjacent silicon steel sheets to reduce eddy current losses and ensure uniform distribution of the overall magnetic field.

2.4 Fastening and fixing

Use high-strength resin adhesive or mechanical pressure to tightly fix the stack of laminations together to prevent the laminations from loosening due to vibration and other factors during operation.

2.5 Winding embedding

In wind turbine generators, due to the harsh working environment and the need for long-term reliable operation, higher requirements are placed on the axial flux stator lamination stack. Therefore, during the design and production process, issues such as corrosion resistance, high temperature resistance, fatigue resistance, and heat dissipation must be fully considered, and corresponding measures such as anti-corrosion coatings, insulation material upgrades, and structural design enhancements must be taken to ensure that the stator lamination stack can be used in complex processes. Long-lasting stability and efficient operation under all conditions.

5. Summary

the axial flux stator lamination stacking process for wind turbine generators is a technical practice that integrates multi-disciplinary knowledge such as material science, precision manufacturing and electrical engineering. Each link directly affects the overall generator Performance and service life are worthy of our continued in-depth research and exploration.

PuTian YouYou Technology Co., Ltd. has many years of production capacity and customized axial flux motor cores. Welcome to Contact our technology.