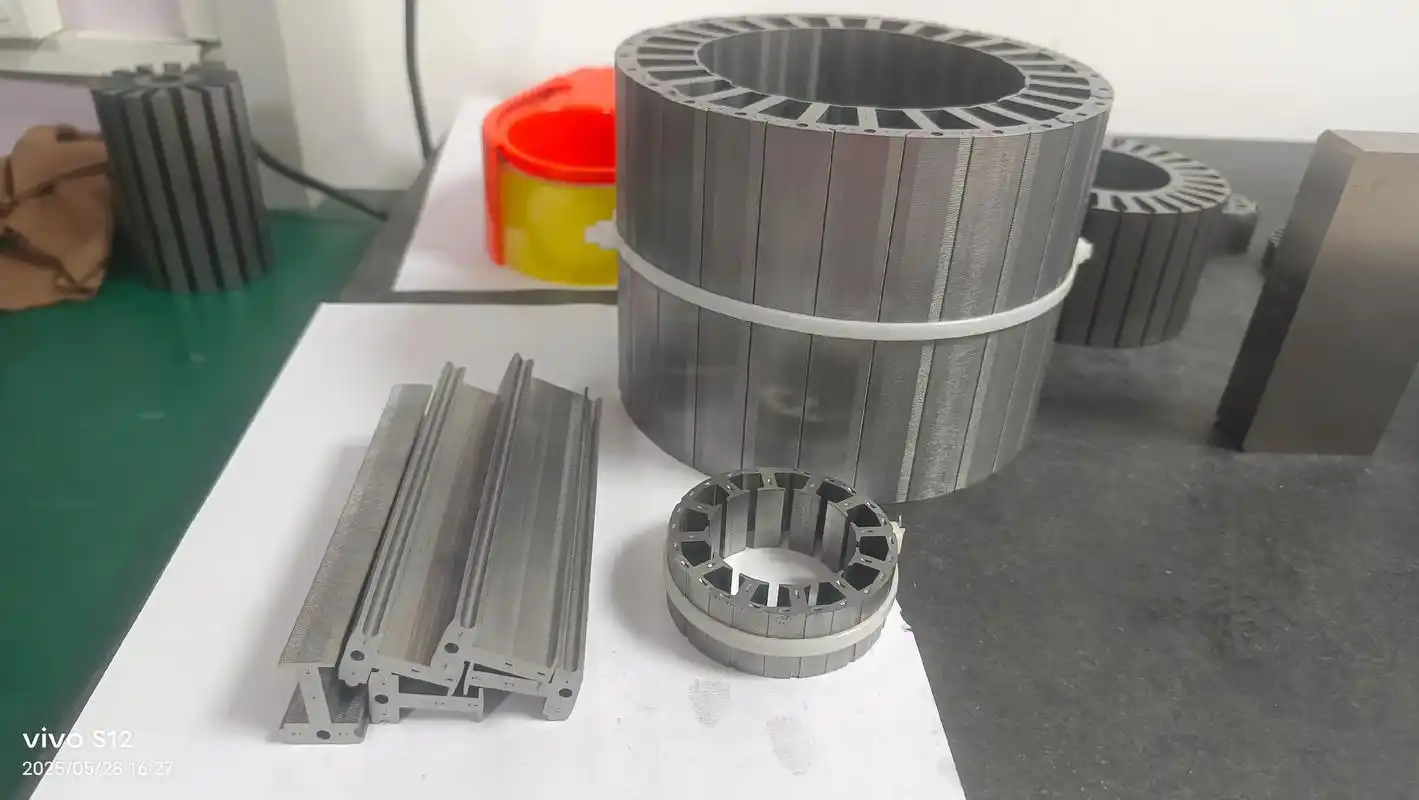

Core Advantages of Segmented Motor Cores

After years of practice in customization and application, segmented motor cores have obvious advantages over integral cores, especially in high-performance, large-size, and customized motor scenarios. Here are the most prominent 6 advantages:

-

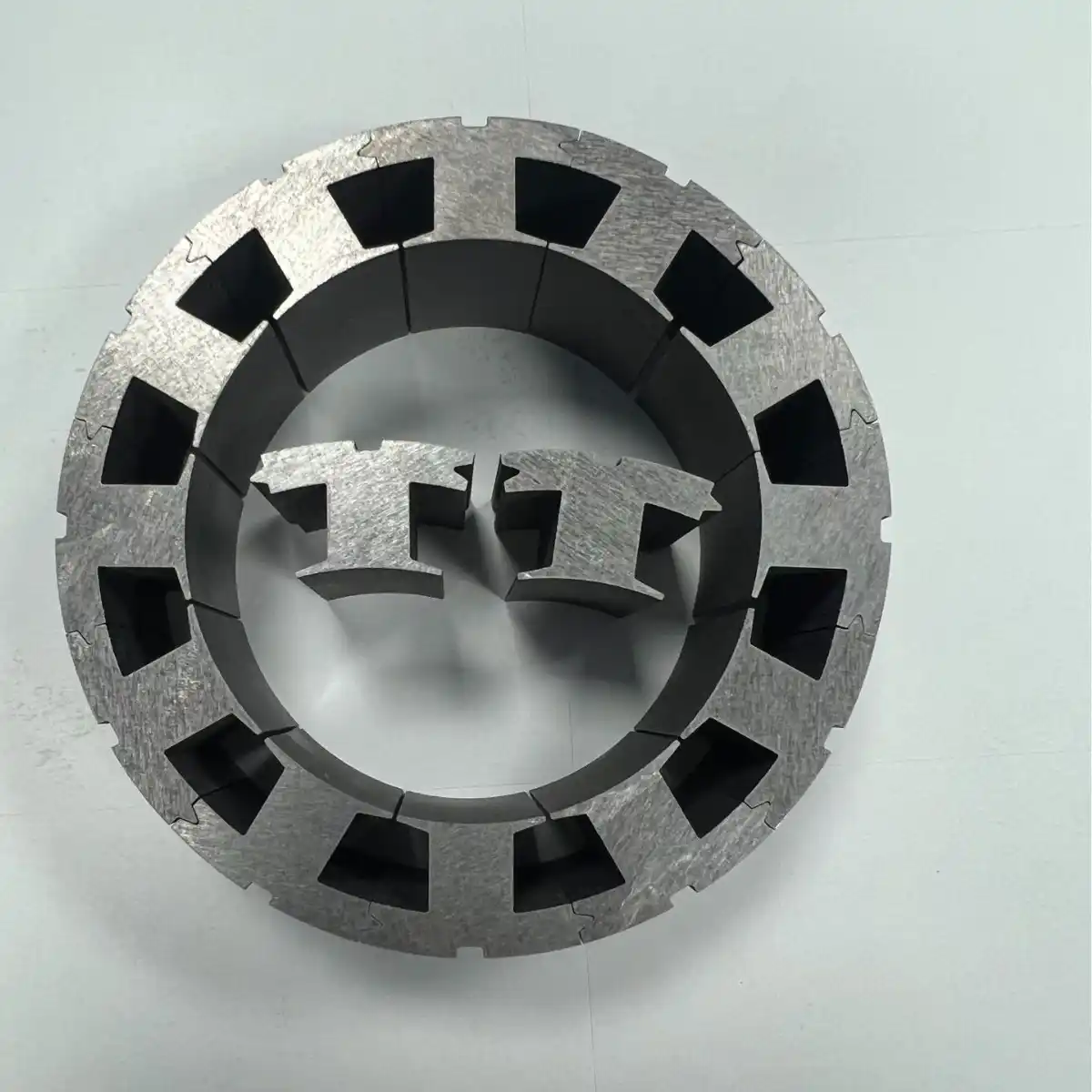

Simplified Winding Process & Higher Slot Fill Rate

The biggest pain point of traditional integral cores is the difficulty in winding—especially for small-slot, high-density winding scenarios. Segmented cores can be wound separately for each segment before assembly, which not only makes the winding operation more manageable and precise but also effectively improves the slot fill rate. For example, in our custom NEV motor core projects, the slot fill rate of segmented cores can reach 70%-75%, while the integral core is usually only 60%-65%. Higher slot fill rate directly improves motor efficiency and power density, reducing energy loss during operation.

-

Improved Material Utilization & Reduced Waste

Traditional integral cores are stamped from a whole piece of silicon steel sheet, and the material around the slots and the central area becomes waste, resulting in low material utilization (usually only 65%-70%). Segmented cores are stamped with small silicon steel sheets matching the size of each segment, which greatly reduces stamping waste. Our factory’s data shows that the material utilization rate of segmented cores can reach 85%-90%, significantly reducing raw material costs—especially for high-performance silicon steel sheets (such as B5000=1.67T) that account for more than 30% of the motor total cost.

-

Easier Transportation & Assembly

For large-size motors (such as industrial motors above 100kW), integral cores are large in size, heavy in weight, and difficult to transport and install—even requiring special equipment to hoist. Segmented cores are small in single-segment size and light in weight, which can be transported separately and assembled on-site, greatly reducing transportation and assembly costs and improving construction efficiency. This advantage is particularly obvious in large-scale equipment such as wind power generators and marine motors.

-

Flexible Material Selection & Optimized Magnetic Performance

Segmentation allows manufacturers to use different silicon steel materials (including oriented silicon steel) for different parts of the stator and rotor, optimizing each component according to its specific functional requirements. For example, high-magnetic-permeability silicon steel sheets can be used for the tooth part to enhance magnetic flux density, and low-loss silicon steel sheets can be used for the yoke part to reduce eddy current loss. This flexible material matching can improve motor efficiency by 3%-5% compared with integral cores using a single material.

-

Reduced Eddy Current Loss & Better Heat Dissipation

The segmented structure, combined with insulation materials (such as insulation paper) between adjacent segments, can effectively reduce electromagnetic eddy currents and turbulence in the core, thereby reducing eddy current loss and core heating. At the same time, the gaps between segments form natural heat dissipation channels, which improve the heat dissipation performance of the core—critical for maintaining optimal motor performance under high-speed or heavy-load conditions, such as NEV motors operating at 20,000rpm.

-

High Adaptability to Customization

As a custom motor core factory, we found that segmented cores are more suitable for personalized customization needs. Whether it is a special-shaped slot design, non-standard size, or special performance requirements (such as high torque, low noise), segmented cores can be adjusted by changing the shape, size, and number of segments, without redeveloping a large integral stamping die—greatly reducing customization costs and shortening the development cycle.

Unavoidable Disadvantages of Segmented Motor Cores

While segmented motor cores have many advantages, they also have some inherent disadvantages due to their modular structure, which need to be paid attention to in practical applications:

Higher Assembly Precision Requirements

The complete core is formed by assembling multiple segments, which requires extremely high assembly precision—especially the coaxiality and flatness of the segments. If the assembly error exceeds 0.1mm, it will lead to uneven magnetic flux distribution, increased noise, and even affect the normal operation of the motor. This requires manufacturers to have advanced assembly equipment and strict quality control systems, which will increase the production cost to a certain extent.

Increased Cogging Torque & Noise Risk

Compared with traditional integral cores, segmented cores may have increased cogging torque due to the joint gaps between segments, which can lead to higher noise levels and reduced average torque in some scenarios. Although this problem can be alleviated by optimizing the segment shape and assembly process (such as segmented skewed pole technology), it cannot be completely eliminated, and is not suitable for ultra-low noise motor scenarios (such as medical equipment motors).

Higher Initial Production Cost for Small-Batch Orders

Although segmented cores can reduce material waste, they need to develop stamping dies for each segment. For small-batch custom orders (such as less than 100 pieces), the die cost per unit product is relatively high—higher than that of integral cores. Therefore, segmented cores are more cost-effective for large-batch production, while integral cores may be more suitable for small-batch, standard-size motor projects.

Potential Impact on Structural Strength

The joint between segments is the weak point of the core structure. Under high-speed rotation (such as NEV rotor cores), the centrifugal force may cause loosening of the segments, affecting the structural stability of the core. Although this problem can be solved by using high-strength bonding agents or clamping structures, it will increase the production process and cost.

Segmented Motor Core vs. Integral Motor Core: Detailed Comparison Table

To help you better distinguish between segmented cores and integral cores, we have sorted out a detailed comparison table based on our actual production and customization experience, covering key indicators such as performance, cost, and application scenarios:

| Comparison Indicator | Segmented Motor Core | Integral Motor Core |

|---|---|---|

| Winding Difficulty | Low, separate winding for each segment; slot fill rate 70%-75% | High, integral winding; slot fill rate 60%-65% |

| Assembly Precision Requirement | High (coaxiality ≤0.1mm) | Low, one-time stamping forming |

| Transportation & Assembly Cost | Low, small and light segments, easy to handle | High, large and heavy, requiring special equipment |

| Eddy Current Loss | Low, insulation between segments reduces eddy currents | High, integral structure leads to more eddy currents |

| Customization Flexibility | High, easy to adjust segment shape/size; low die cost for customization | Low, need to redevelop large stamping dies for customization |

| Cogging Torque & Noise | Slightly higher, need to optimize to reduce noise | Lower, suitable for ultra-low noise scenarios |

| Production Cost (Large Batch) | Low, material saving offsets die cost | High, high material waste |

| Production Cost (Small Batch) | High, die cost per unit is high | Low, no need for multiple segment dies |

| Suitable Application Scenarios | NEVs, high-power industrial motors, large-size equipment, customized motors | Small and medium-sized standard motors, small-batch orders, ultra-low noise equipment (medical, household appliances) |

Future Trends of Segmented Motor Cores (2026-2030)

With the rapid development of new energy, industrial intelligence, and energy conservation and emission reduction policies, segmented motor cores, as a high-efficiency and energy-saving core component, will show three clear development trends in the next 5 years:

Integration of New Materials to Further Reduce Losses

In the future, segmented cores will gradually adopt new high-performance materials to optimize magnetic properties and reduce energy loss. For example, non-amorphous alloy strips (0.02mm thick) can reduce eddy current loss by 70% compared with traditional silicon steel sheets, and nanocrystalline materials can further improve magnetic permeability. At the same time, the combination of different materials (hybrid material segmented cores) will become more common—for example, using oriented silicon steel for the tooth part and non-amorphous alloy for the yoke part to achieve the balance between performance and cost.

Intelligence of Production & Assembly Processes

To solve the problem of high assembly precision requirements, segmented core production will gradually realize full automation and intelligence. Our factory is already piloting the integration of robotic assembly, laser positioning, and online detection technologies—reducing assembly errors to less than 0.05mm, improving production efficiency by 40%, and ensuring the consistency of product quality. In addition, 3D printing technology may be applied to the production of small-batch, special-shaped segmented cores, further reducing die costs and shortening the customization cycle.

Wider Application in New Energy & High-Power Fields

With the acceleration of the global NEV penetration rate and the upgrading of industrial motors to high efficiency and energy saving, segmented cores will become the mainstream choice in these fields. For example, in NEVs, segmented cores can improve motor efficiency and power density, extending the driving range; in wind power and solar power generation equipment, segmented cores can adapt to large-size motor design and harsh working environments. At the same time, with the development of axial flux motors, segmented cores will be more widely used due to their advantages in flatness and magnetic flux distribution optimization.

Development Towards Lightweight & Miniaturization

In fields such as NEVs and aerospace motors, lightweight and miniaturization are important development directions. Segmented cores can realize the optimal design of the core structure (such as hollow segments, thin-walled design) on the premise of ensuring structural strength, reducing the weight of the core by 10%-15% compared with integral cores. This will help reduce the overall weight of the motor and equipment, improving energy efficiency and operational performance.

Conclusion: Is Segmented Motor Core Suitable for Your Project?

As a professional custom motor core manufacturing factory, we believe that there is no absolute "good" or "bad" between segmented cores and integral cores—only "suitable" or "unsuitable". If your project is a large-batch, high-performance, large-size, or customized motor (such as NEV motors, industrial high-power motors), segmented cores are definitely a more cost-effective choice, which can help you reduce costs, improve efficiency, and gain market competitiveness.

If your project is a small-batch, standard-size, or ultra-low noise motor (such as medical equipment motors, small household appliance motors), integral cores may be more suitable. Of course, with the continuous upgrading of our production technology, we can also provide customized solutions for small-batch segmented core orders, reducing your initial investment cost.

If you have any questions about the selection, customization, or application of segmented motor cores, please feel free to contact us—our professional engineering team will provide you with one-to-one technical guidance and quotation services based on your specific project needs.

About Youyou Technology

Youyou Technology Co., Ltd. specializes in the manufacture of Self-bonding precision cores made of various soft magnetic materials, including Self-bonding silicon steel, ultra-thin silicon steel, and Self-bonding specialty soft magnetic alloys. We utilize advanced manufacturing processes for precision magnetic components, providing advanced solutions for soft magnetic cores used in key power components such as high-performance motors, high-speed motors, medium-frequency transformers, and reactors.

The company Self-bonding precision core products currently include a range of silicon steel cores with strip thicknesses of 0.05mm(ST-050), 0.1mm(10JNEX900/ST-100), 0.15mm, 0.2mm(20JNEH1200/20HX1200/ B20AV1200/20CS1200HF), and 0.35mm(35JNE210/35JNE230/ B35A250-Z/35CS230HF), as well as specialty soft magnetic alloy cores including Hiperco 50 and VACODUR 49 and 1J22 and 1J50.