Why BLDC Motors Dominate Heavy Drones? A Quick Comparison to Brushed Motors

Before diving into motor cores, it’s critical to understand why BLDC motors are the gold standard for heavy drones. While brushed motors are cheaper upfront, they fail to meet the durability and efficiency needs of heavy-lift missions. The table below compares BLDC motors vs. brushed motors for heavy drone applications—key insights that align with top YOUYOU TECH search queries for heavy UAV propulsion systems:

| Performance Metric | BLDC Motors (Ideal for Heavy Drones) | Brushed Motors (Not Suitable for Heavy Drones) | Key Advantage for Heavy Drones |

|---|---|---|---|

| Efficiency | 85–95% (high, minimizes battery drain) | 60–75% (low, wastes energy) | Extends flight time (20–60+ mins for commercial missions) |

| Torque Density | High (up to 100+ kg thrust, low RPM) | Low (cannot support heavy payloads) | Powers cargo delivery, agricultural spraying, and heavy sensor loads |

| Durability & Maintenance | Low maintenance, 1800+ hours lifespan, no brush wear | High maintenance, 200–500 hours lifespan, frequent brush replacement | Withstands harsh environments (dust, moisture, extreme temps) |

| Heat Generation | Low (electronic commutation reduces heat buildup) | High (brush friction causes overheating) | Prevents motor failure during long-haul, high-load flights |

| Noise Level | Low (smooth, quiet operation) | High (brush friction creates noise) | Ideal for noise-sensitive missions (surveillance, urban cargo delivery) |

The data speaks for itself: BLDC motors are the only choice for heavy drones—and their performance hinges entirely on the motor core. As a custom core manufacturer, we specialize in solving the unique challenges of heavy drone BLDC motors by designing cores that amplify their natural advantages.

Custom vs. Off-the-Shelf Motor Cores: The Critical Difference for Heavy Drone BLDC Motors

One of the most common mistakes heavy drone manufacturers make is using off-the-shelf motor cores to save time. While this may work for consumer drones, heavy-lift missions demand cores tailored to specific motor specs (3510, 4114, 5008, 240110 models) and mission requirements. Below is a detailed comparison of our custom motor cores vs. off-the-shelf alternatives—optimized for YOUYOU TECH searches like “custom BLDC core vs off-the-shelf” and “heavy drone motor core performance”:

| Key Performance Factor | Our Custom Motor Cores (Heavy Drone-Optimized) | Off-the-Shelf Motor Cores | Impact on Heavy Drone BLDC Motors |

|---|---|---|---|

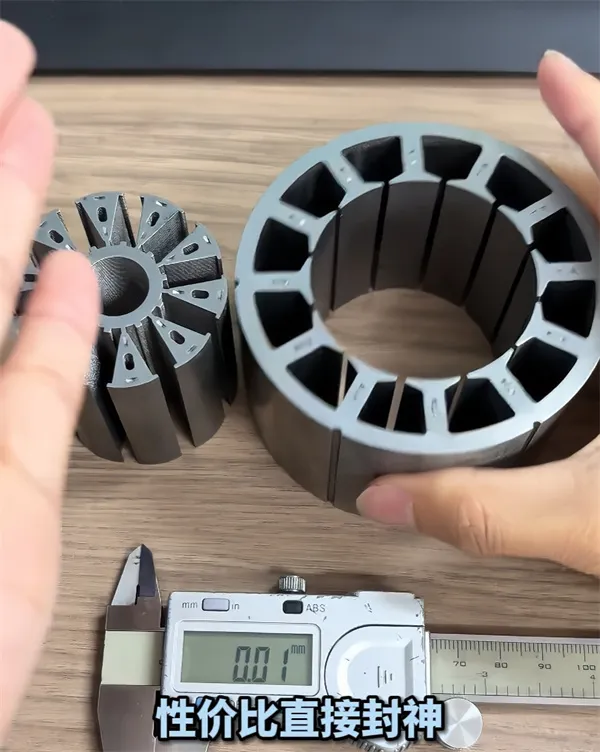

| Material Quality & Lamination | High-grade silicon steel (0.2–0.35mm thin laminations), amorphous alloy options; precision annealing to reduce stress; corrosion-resistant coatings | Low-grade silicon steel (0.5mm+ thick laminations); no annealing; basic coating (if any) | Custom cores reduce iron loss by 30–40%, improving efficiency and reducing heat buildup; off-the-shelf cores waste energy and overheat |

| Torque Optimization | Custom slot shapes (optimized for magnetic flux), tailored stack height, and magnetic circuit design to maximize torque density (173N·m+ for high-thrust models) | Generic slot shapes, one-size-fits-all stack height; no torque optimization | Custom cores enable 25–35% higher torque output without increasing motor size; off-the-shelf cores limit payload capacity |

| Iron Loss (Eddy Current + Hysteresis) | Minimized (≤2.5W/kg at 50Hz); optimized lamination stacking to reduce eddy currents | High (≥5W/kg at 50Hz); poor lamination stacking | Custom cores extend battery life by 20–30%; off-the-shelf cores reduce flight time and require larger batteries (adding weight) |

| Durability & Environmental Resistance | Withstands -40°C to 85°C, high vibration, dust, and moisture; structural design optimized for heavy-lift flight stress | Limited temperature range (-20°C to 60°C); poor vibration resistance; no corrosion protection | Custom cores last 2–3x longer; off-the-shelf cores fail prematurely in harsh industrial/remote environments |

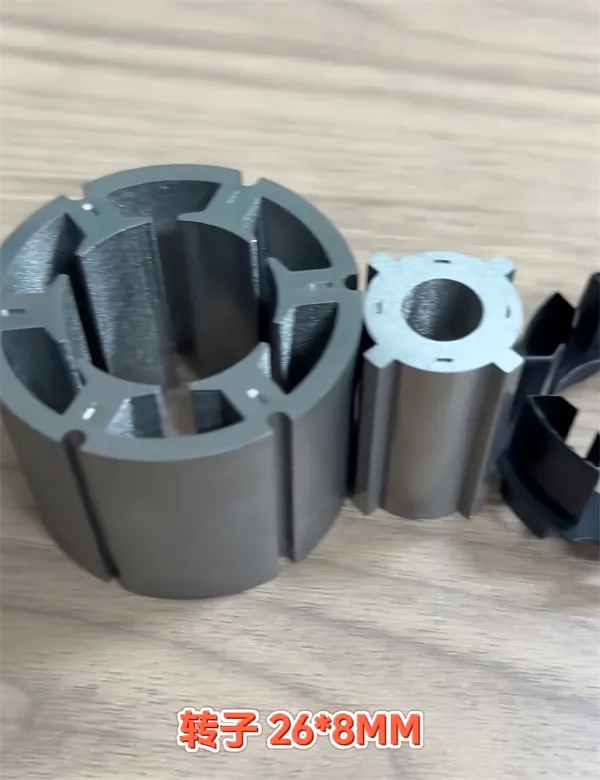

| Motor Size Compatibility | Tailored to common heavy drone BLDC motor sizes (3510, 4114, 5008, 240110) and custom OEM designs; seamless integration with stator/rotor | Generic sizes; often require modifications to fit heavy drone motors | Custom cores eliminate fitment issues and reduce assembly time; off-the-shelf cores cause delays and performance gaps |

| Cost-Effectiveness (Long-Term) | Higher upfront cost, but lower total cost of ownership (fewer replacements, less maintenance, better motor performance) | Lower upfront cost, but higher long-term cost (frequent replacements, motor failures, lost missions) | Custom cores reduce total operational costs by 40%+ for heavy drone fleets |

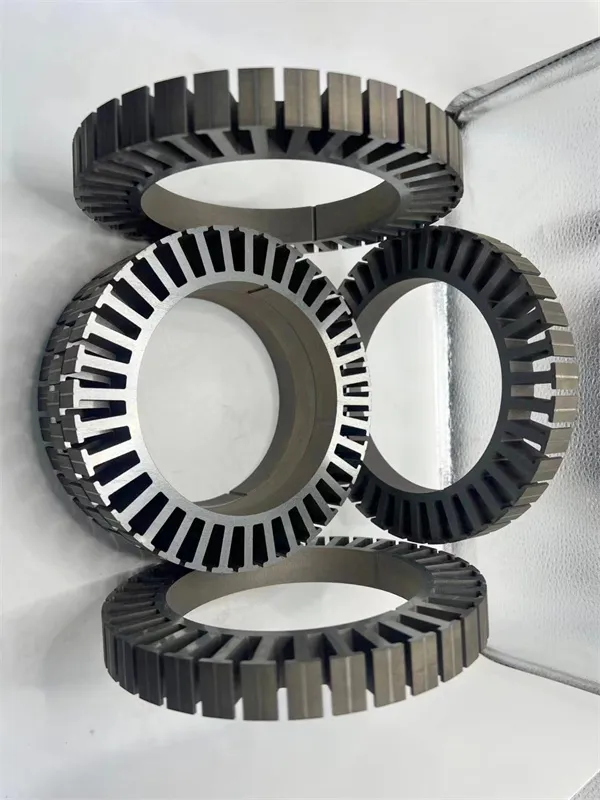

Our Custom BLDC Motor Core Solutions for Heavy Drone Manufacturers

As a dedicated motor core custom manufacturer, we don’t just “make cores”—we partner with heavy drone OEMs to design solutions that solve their most pressing challenges. Based on the latest industry trends (per YOUYOU TECH search) and our experience with global heavy drone brands, our core offerings include:

Material Customization

Choose from high-grade silicon steel, amorphous alloy, or customized magnetic materials (based on your motor’s power, torque, and environmental needs). We source materials that meet ISO 9001 and IATF 16949 standards, ensuring consistent performance across every batch.

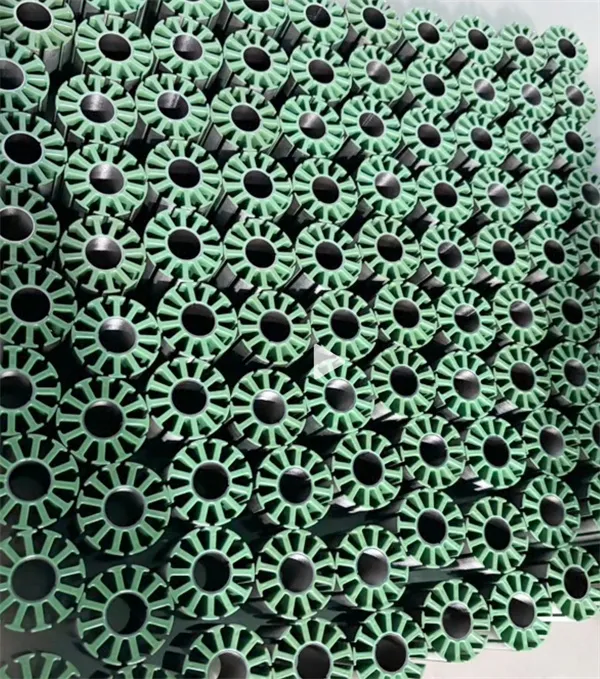

Precision Design & Prototyping

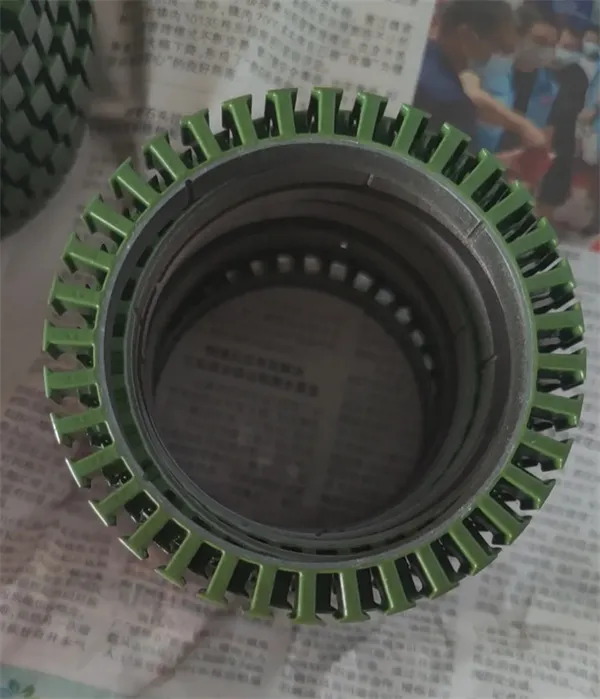

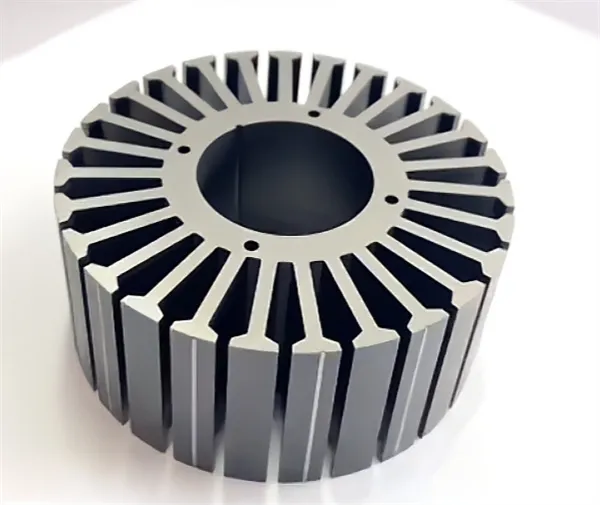

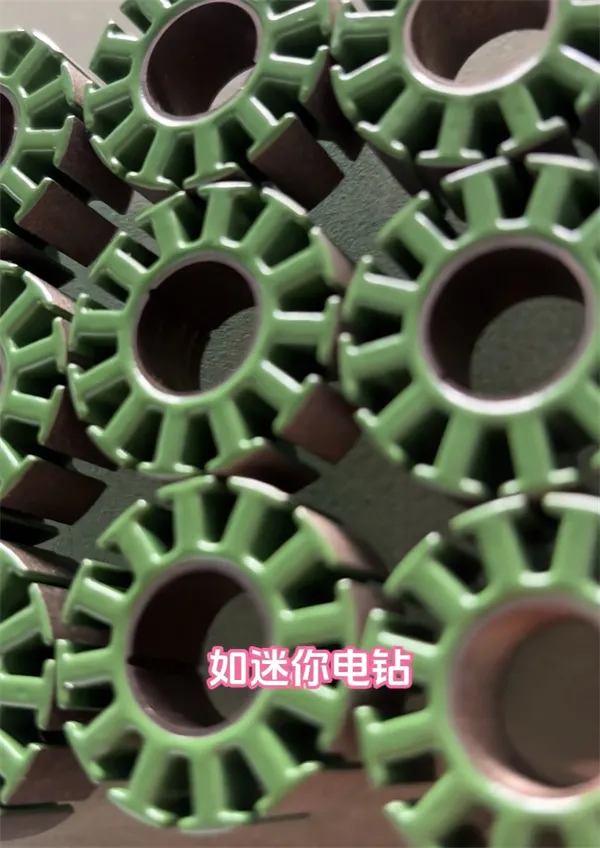

Our engineering team works with your specs to optimize slot design, lamination thickness, and stack height—then creates rapid prototypes (7–10 days) to test performance before full-scale production. We specialize in cores for both inner-rotor (high-speed fixed-wing heavy drones) and outer-rotor (low-RPM, high-torque multirotors) BLDC motors.

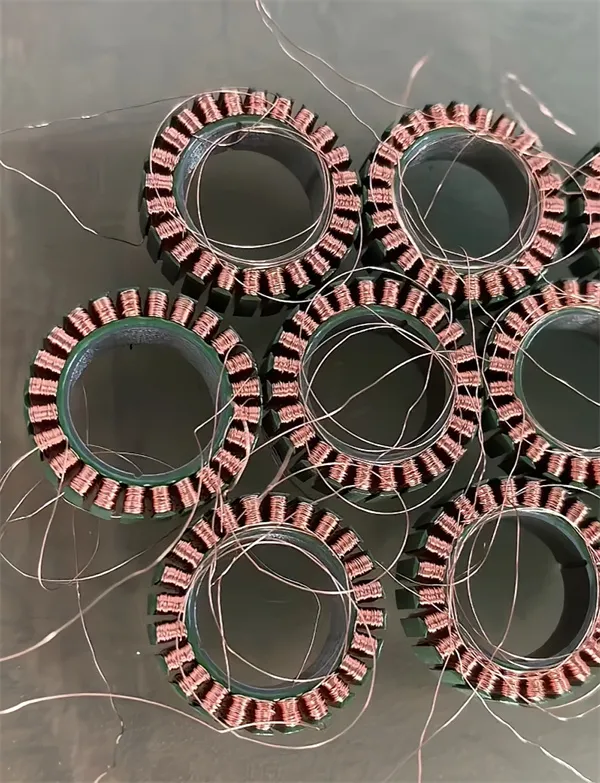

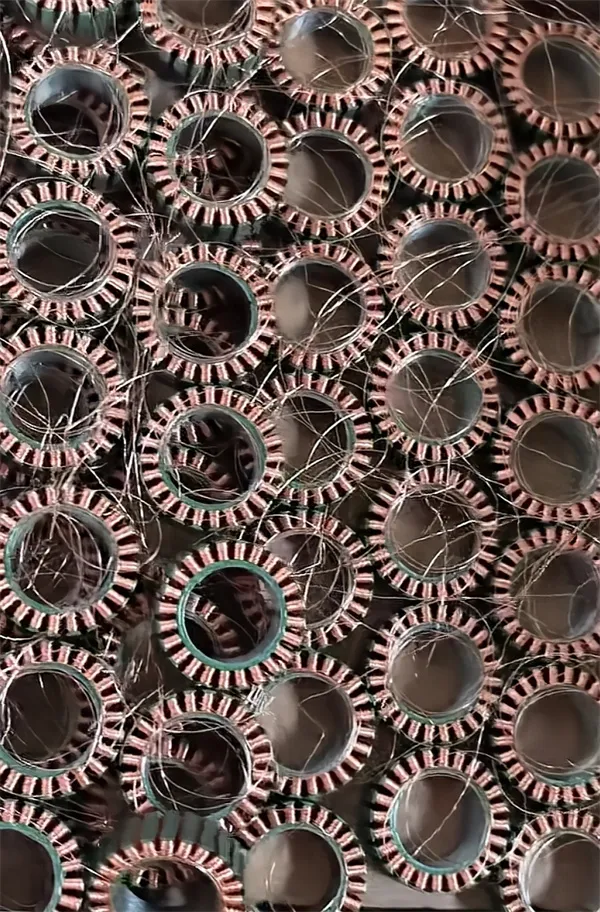

Industrial-Grade Manufacturing

We use advanced stamping (high-precision dies for slot accuracy), automated stacking, and strict quality control (magnetic performance testing, iron loss testing, dimensional checks) to ensure every core meets your exact standards. Our production capacity supports both small-batch prototypes and large-scale OEM orders (10,000+ units/month).

Mission-Specific Optimization

Whether you need corrosion-resistant cores for agricultural drones, high-torque cores for cargo drones, or low-noise cores for surveillance drones, we tailor our designs to your unique mission requirements.

Material Comparison: Which Core Material Is Best for Your Heavy Drone BLDC Motor?

Another top YOUYOU TECH search query for heavy drone BLDC motors is “best material for BLDC motor cores.” The right material depends on your motor’s power, flight time, and environment—so we’ve compiled a comparison of the most common core materials we use for heavy drone applications:

| Core Material | Iron Loss (W/kg at 50Hz) | Torque Density | Durability | Best for Heavy Drone Applications |

|---|---|---|---|---|

| High-Grade Silicon Steel (0.2mm) | 1.8–2.5 | High | Excellent | General-purpose heavy drones (cargo, inspection, agriculture) – most popular choice |

| Amorphous Alloy | 0.8–1.5 | Very High | Excellent | Long-flight missions (≥40 mins), high-power motors (400V+, 127A) |

| Silicon Steel (0.35mm) | 2.6–3.5 | Medium-High | Good | Cost-sensitive heavy drones (entry-level industrial UAVs) |

Why Partner With Us for Your Heavy Drone BLDC Motor Cores?

The heavy drone industry is growing fast—and the competition is fierce. To stand out, you need BLDC motors that outperform the rest—and that starts with a custom core from a manufacturer who understands your needs. Here’s why heavy drone OEMs worldwide choose us:

- Heavy Drone Expertise: We don’t serve every industry—we specialize in motor cores for heavy drones and BLDC motors, so we understand the unique challenges of high-load, long-flight missions.

- TECH-Optimized Performance: Our cores are designed to align with the most searched-for heavy drone BLDC motor features (high torque, low iron loss, durability) – helping your motors perform better and your brand rank higher.

- End-to-End Support: From initial design and prototyping to production and quality control, we’re with you every step of the way. Our engineering team is available to answer questions and refine designs until you’re satisfied.

- Proven Track Record: We’ve partnered with OEMs building heavy drones for logistics, agriculture, defense, and inspection—delivering cores that power motors with 100kg+ thrust and 1800+ hours of trouble-free operation.

Ready to Elevate Your Heavy Drone BLDC Motor Performance?

Whether you’re designing a new heavy drone BLDC motor, upgrading an existing model, or need a custom core for a niche mission, we’re here to help. Our team will work with you to understand your specs, optimize your core design, and deliver a solution that meets your performance, budget, and timeline needs.

Request a Technical ConsultationContact us today to discuss yor heavy drone BLDC motor core requirements. Let’s build a core that powers your drone’s success—and helps you stand out in the booming heavy drone market.

About Youyou Technology

Youyou Technology Co., Ltd. specializes in the manufacture of Self-bonding precision cores made of various soft magnetic materials, including Self-bonding silicon steel, ultra-thin silicon steel, and Self-bonding specialty soft magnetic alloys. We utilize advanced manufacturing processes for precision magnetic components, providing advanced solutions for soft magnetic cores used in key power components such as high-performance motors, high-speed motors, medium-frequency transformers, and reactors.

The company Self-bonding precision core products currently include a range of silicon steel cores with strip thicknesses of 0.05mm(ST-050), 0.1mm(10JNEX900/ST-100), 0.15mm, 0.2mm(20JNEH1200/20HX1200/ B20AV1200/20CS1200HF), and 0.35mm(35JNE210/35JNE230/ B35A250-Z/35CS230HF), as well as specialty soft magnetic alloy cores including Hiperco 50 and VACODUR 49 and 1J22 and 1J50.