JNHF-Core

Gradient high-silicon steel sheet with low silicon content at the center portion and 0.065 silicon near the outer surface areas.

Gradient high-silicon steel sheet with low silicon content at the center portion and 0.065 silicon near the outer surface areas.

|

Low Core Loss Low Core Loss |

For high-frequencies in excess of 5 kHz, outshines even JNEX-Core for low core loss. |

|---|---|

|

Highly Workable |

Excellent workability for pressing, bending,stamping, etc. |

|

Non-oriented |

There is virtually no difference in the characteristics between the rolling direction (L-direction) and the transverse direction (C direction). Therefore, this can be used in a wide range of applications, from stationary machines to rolling machines. |

|

High-saturation magnetic flux density |

Has a high saturation magnetic flux density of 1.85 ~ 1.94 T Using this material in a reactor takes full advantage of the superior DC superimposition characteristics. |

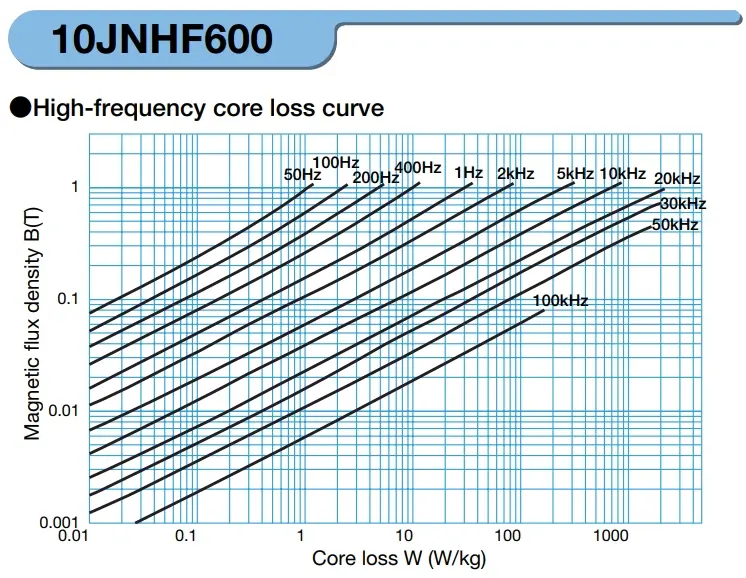

High Frequency Core Loss Curve of 10JNHF600

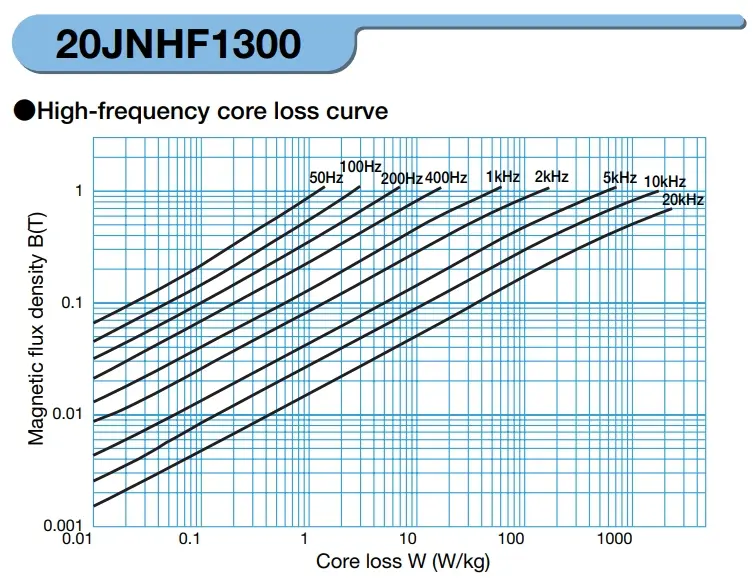

High Frequency Core Loss Curve of 20JNHF1300

A gradient Si steel sheet shows low iron loss in the high-frequency range and lower iron loss deterioration under compressive stresses, therefore, it is suitable for use as the core material of high-speed motors, which have seen considerable downsizing in recent years. By performing shearing and shrink-fitting, the advantages of gradient Si steel as a motor material are investigated in this study. In both shearing and compressive stress experiments, gradient Si steel showed lower iron loss compared to conventional nonoriented electrical steel (0.2 mm thick). By numerical simulation, the efficiencies of the shrink-fitted motors using gradient Si steel and 0.03 Si steel were calculated. The motor using the gradient Si steel showed significantly higher efficiency than that using the 0.03 Si steel. Moreover, even under city driving conditions, gradient Si steel showed good efficiency, because of lower iron loss deterioration. Therefore, gradient Si steel can be used for a wide variety of motors in addition to high-frequency devices.

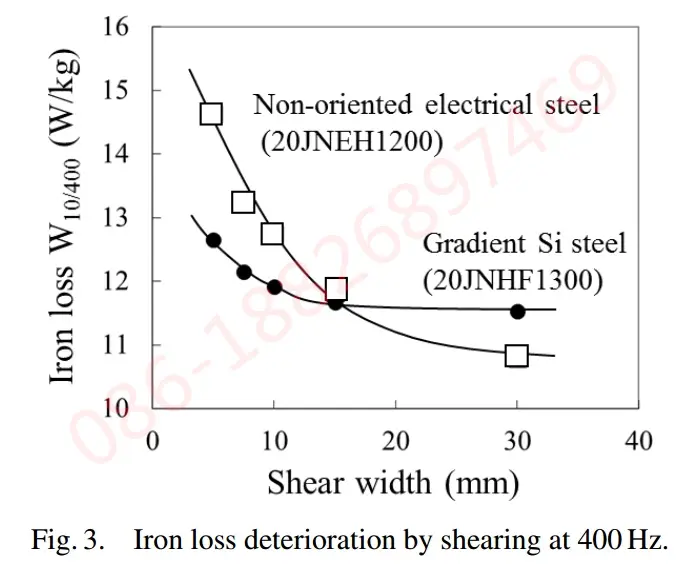

Iron Loss Deterioration By Shearing At 400Hz of 20JNHF1200 and 20JNHF1300

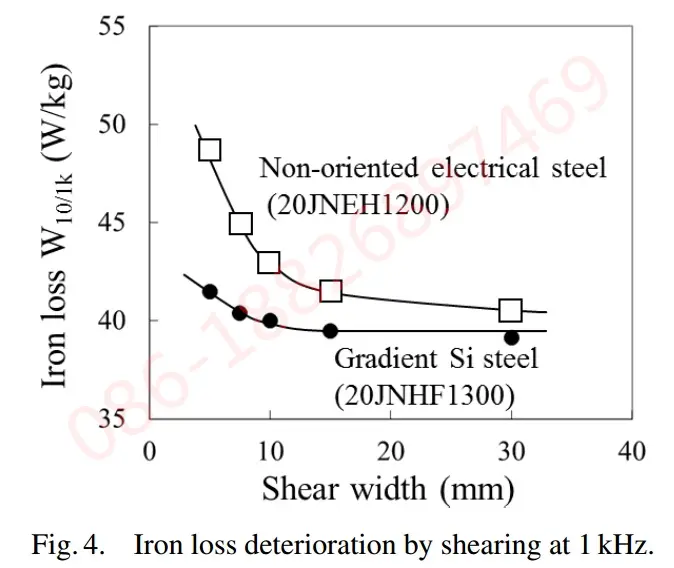

Iron Loss Deterioration By Shearing At 1Khz of 20JNHF1200 and 20JNHF1300

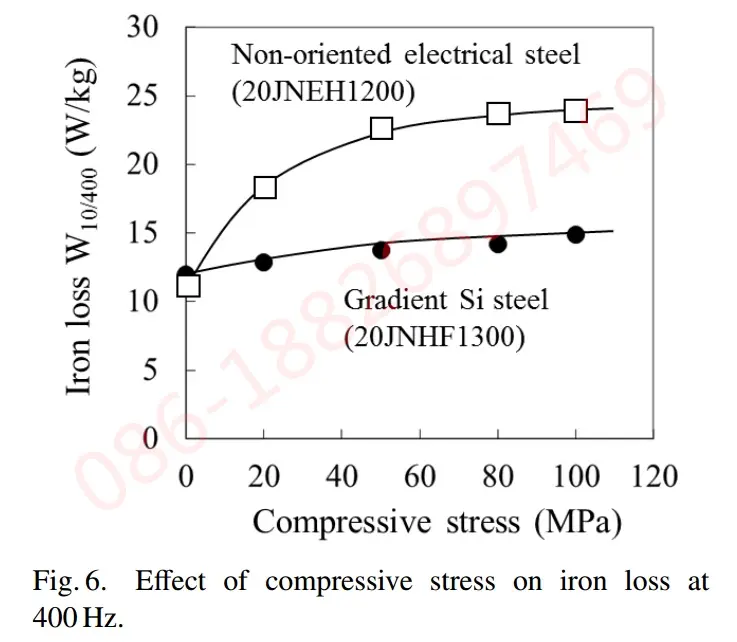

Effect of Compressive Stress On Iron Loss At 400Hz of 20JNHF1200 and 20JNHF1300

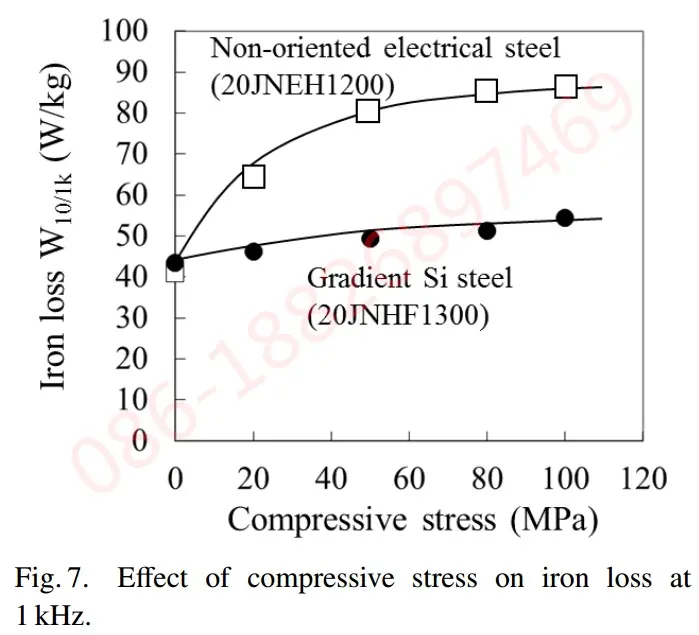

Effect of Compressive Stress On Iron Loss At 1Khz of 20JNHF1200 and 20JNHF1300

Materials in stock of Super Core 10JNEX900/10JNHF600/20JNHF1300

You might also be interested in

Glued motor core, more compact assembly, improve the efficiency and performance of the motor, while also reducing noise and vibration.

Stator glue bonding + EDM method. Fast proofing, testing motor core performance superiority.

Lamination glue is an adhesive used in the production of electronic products, can be used to stack multiple sheets together to form a whole.