What Is Hiperco 50 Lamination Stack?

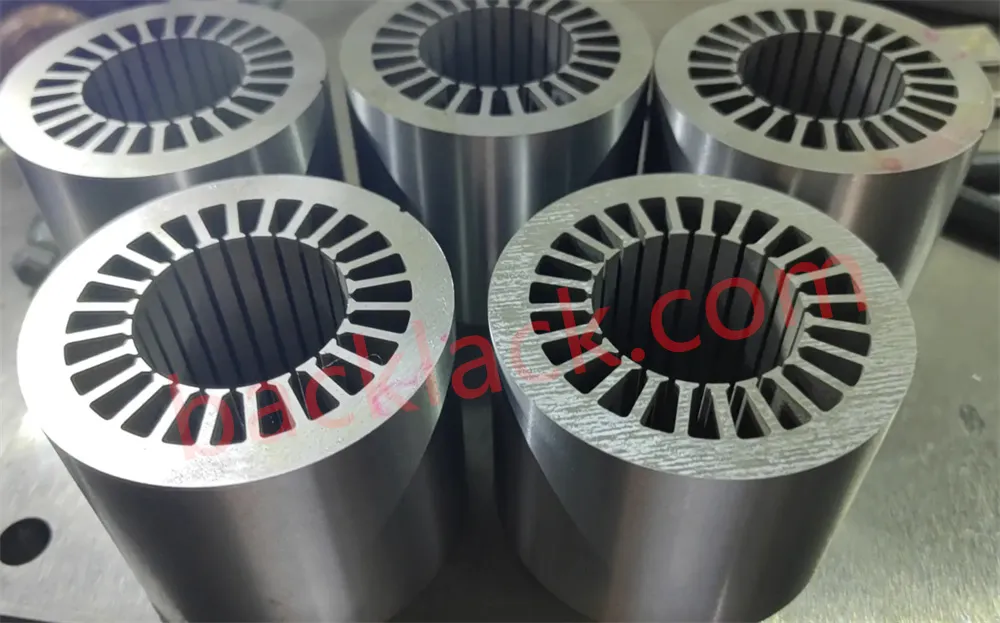

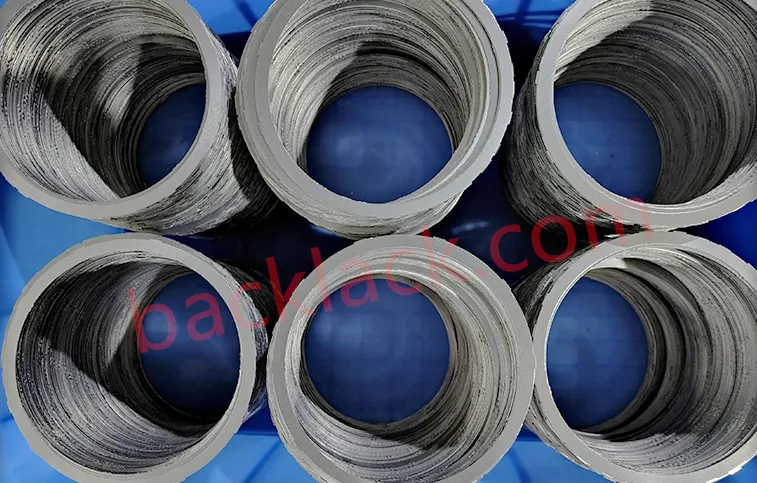

Hiperco 50—also known as 1J22, Permendur, or Vacoflux 50—is a cobalt-iron-vanadium soft magnetic alloy that stands out for its unmatched magnetic saturation (up to 24 kilogauss), significantly higher than standard electrical steel. A Hiperco 50 lamination stack is a layered assembly of thin Hiperco 50 strips, precision-cut and stacked to form the core of motors, generators, and transformers. The lamination design minimizes eddy current losses, while the inherent properties of Hiperco 50 ensure maximum magnetic flux density, making it ideal for compact, high-power motor applications.

Manufactured in compliance with ASTM A801 Alloy 1 standards, our Hiperco 50 lamination stacks leverage the alloy’s unique combination of magnetic and mechanical performance—low coercivity, strong mechanical stability, and excellent machinability when processed correctly. Whether you need small-scale prototypes or large-volume production, we customize every detail to match your specifications.

Key Benefits of Hiperco 50 Lamination Stacks for Your Motors

When you choose custom Hiperco 50 lamination stacks from our factory, you’re investing in motor performance that outperforms traditional electrical steel cores. Here’s what sets them apart:

Ultra-High Magnetic Saturation

With 24 kilogauss magnetic saturation, Hiperco 50 lamination stacks enable higher flux density, allowing you to design smaller, lighter motors without sacrificing power—critical for EVs, aerospace generators, and compact industrial equipment.

Lower Core Losses

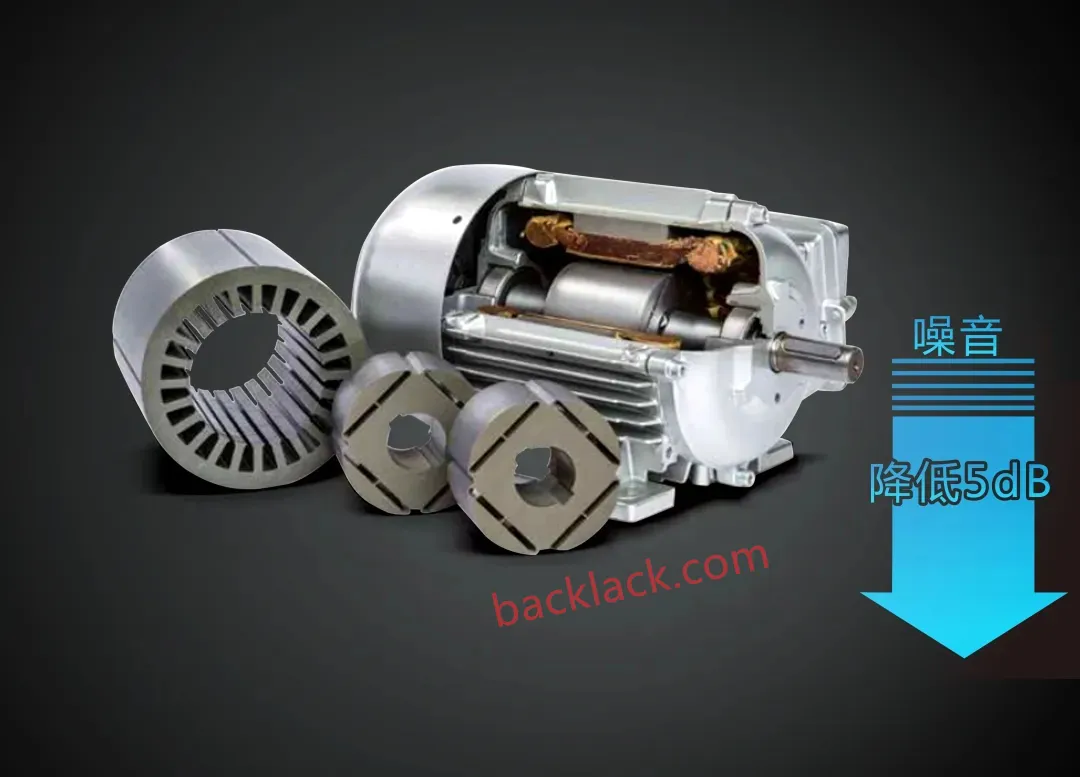

Compared to standard electrical steel, Hiperco 50 reduces eddy current and hysteresis losses, improving motor efficiency and reducing energy consumption—perfect for high-frequency applications like power electronics and precision drives.

Superior Mechanical Strength

Hiperco 50’s cobalt-iron-vanadium composition delivers exceptional tensile strength and durability, even under elevated temperatures and mechanical stress—ideal for harsh environments like aerospace and heavy-duty industrial motors.

Customizable Performance

Through precise heat treatment (including controlled annealing) and grain growth management, we tailor the magnetic and mechanical properties of your Hiperco 50 lamination stack to your exact motor requirements.

Wide Temperature Tolerance

Hiperco 50 maintains its magnetic performance at high temperatures, making it suitable for motors operating in extreme conditions—from aircraft engines to industrial heating systems.

To better illustrate the advantages of Hiperco 50 lamination stacks, we’ve compiled a detailed comparison with standard electrical steel—one of the most commonly used materials for motor cores. This table clearly shows why Hiperco 50 is the preferred choice for high-performance motor applications.

| Performance Parameter | Hiperco 50 Lamination Stack | Standard Electrical Steel |

|---|---|---|

| Magnetic Saturation (Kilogauss) | Up to 24 | 15-18 |

| Core Loss (at 50Hz, 1.5T) | Low (≤3.5 W/kg) | Higher (4.5-6.0 W/kg) |

| Tensile Strength (MPa) | ≥690 | 400-550 |

| Temperature Tolerance | Excellent (maintains performance up to 200°C) | Moderate (performance degrades above 150°C) |

| Ideal Application | Aerospace, EVs, high-power precision motors | General industrial motors, low-power appliances |

Our Custom Hiperco 50 Lamination Stack Manufacturing Capabilities

As a dedicated motor core custom factory, we understand that every motor design is unique. That’s why we offer end-to-end customization for Hiperco 50 lamination stacks, backed by advanced manufacturing technology and strict quality control:

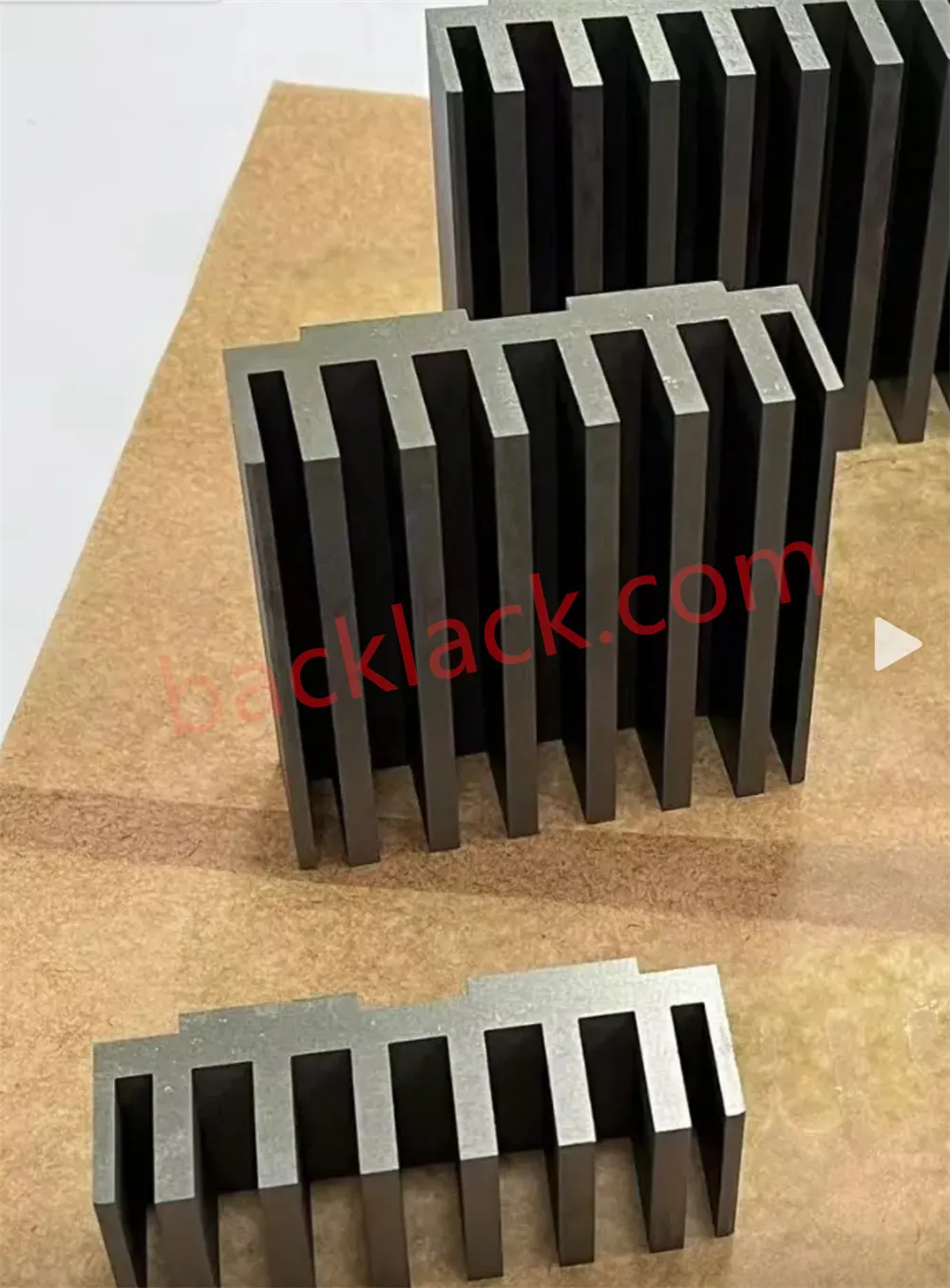

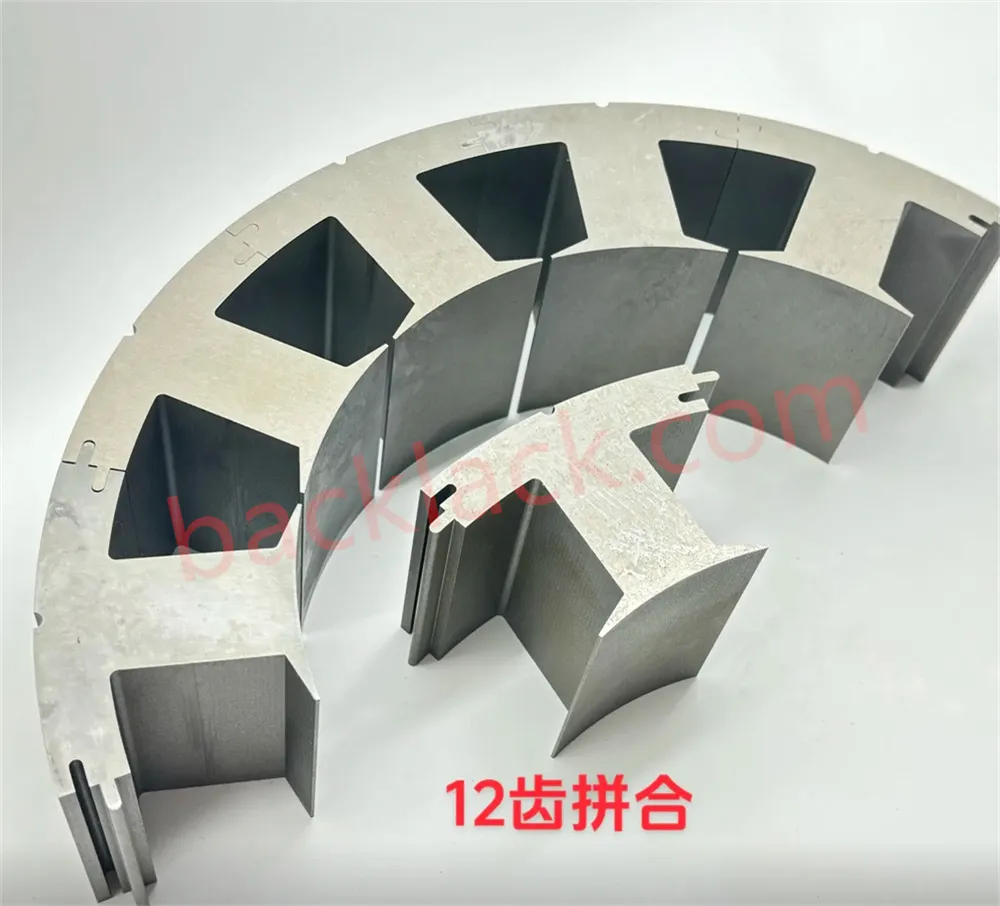

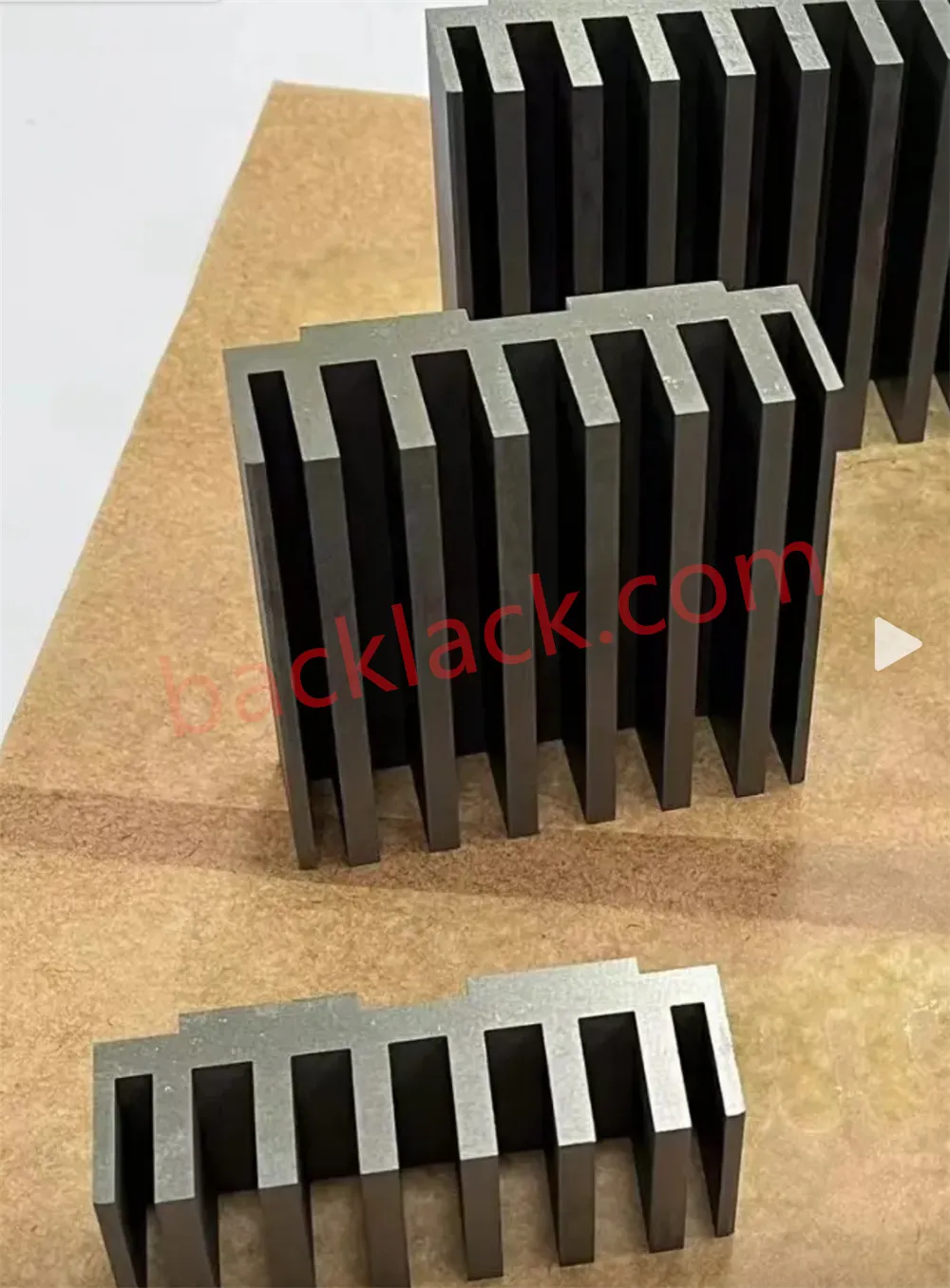

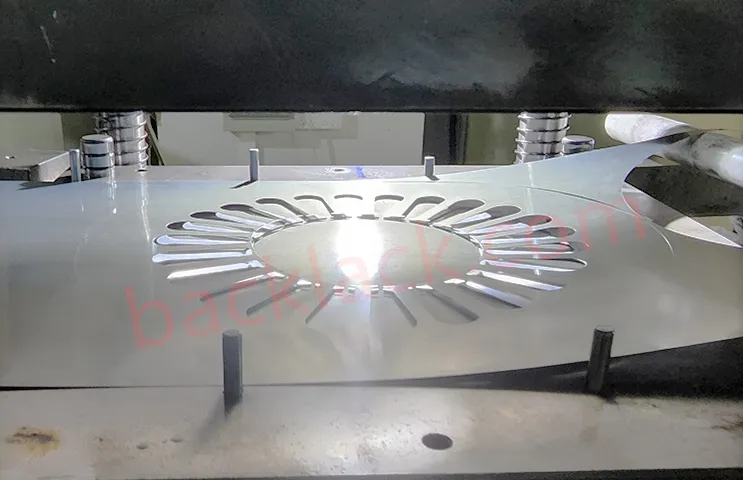

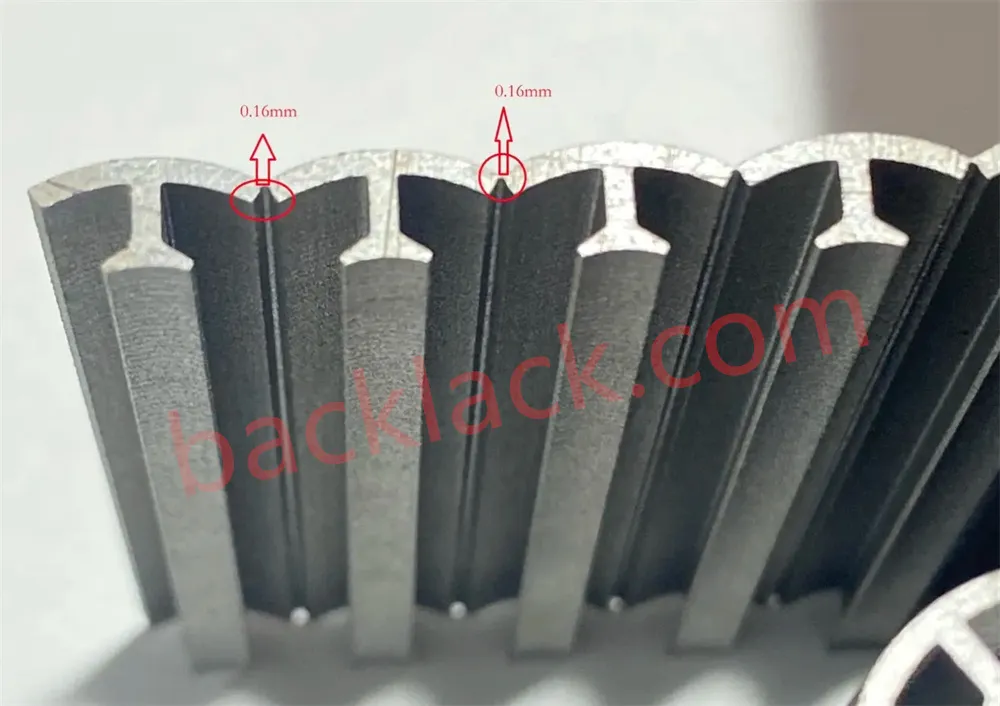

- Precision Cutting & Stamping: We use state-of-the-art laser cutting and high-speed stamping equipment to produce Hiperco 50 laminations with tight tolerances (thickness tolerance ±10% for strips over 0.05mm, ±15% for 0.01-0.05mm), ensuring perfect alignment and stack integrity.

- Custom Thickness & Sizes: We work with Hiperco 50 strip, coil, and plate materials, offering lamination thicknesses from 0.1mm to 0.5mm and custom sizes to match your rotor, stator, or transformer core design.

- Heat Treatment Expertise: Our team specializes in Hiperco 50 heat treatment—including 880°C rapid quenching and controlled annealing—to optimize magnetic properties and mechanical strength, ensuring consistent performance across every stack.

- Surface Treatment Options: We offer insulation coatings (e.g., epoxy, varnish) to further reduce eddy current losses and prevent corrosion, extending the lifespan of your motor core.

- Quality Assurance: Every Hiperco 50 lamination stack undergoes rigorous testing—magnetic performance, dimensional accuracy, and mechanical strength—to meet ASTM A801 standards and your specific quality requirements.

Applications of Custom Hiperco 50 Lamination Stacks

Hiperco 50 lamination stacks are trusted in industries where high performance and reliability are non-negotiable. Our custom cores are used in:

Aerospace & Defense

Aircraft generators, rotor/stator cores for aerospace motors, and precision electromagnetic components that require compact design and high-temperature resistance.

Electric Vehicles (EVs) & Hybrid Vehicles

High-power density traction motors, where smaller, lighter cores improve battery efficiency and overall vehicle performance.

Industrial Automation

Precision servo motors, high-frequency transformers, and magnetic amplifiers for robotics, CNC machines, and industrial drives. 24 hours.

Power Electronics

Choke coils, inducers, and high-efficiency transformers that demand low core losses and high magnetic flux density. major updates.

Consumer Electronics

Actuators for haptic devices, speakers, and sensors, where Hiperco 50 delivers the highest force density for compact components.

Why Choose Our Factory for Your Hiperco 50 Lamination Stack Needs?

When it comes to custom Hiperco 50 lamination stacks, experience, precision, and customization matter. Here’s why manufacturers worldwide trust us:

- Specialized Expertise: We focus exclusively on motor core manufacturing, with years of experience working with Hiperco 50 and other high-performance soft magnetic alloys like Permendur and Vacoflux 50.

- Flexible Production: From small-batch prototypes to mass production, we adapt to your order size and timeline, ensuring on-time delivery without compromising quality.

- Cost-Effective Solutions: Our optimized manufacturing processes and direct material sourcing (including Carpenter Hiperco 50 alloys) help reduce costs while maintaining premium quality.

- Customer-Centric Service: Our engineering team works closely with you from design to delivery, helping you select the right Hiperco 50 specifications and optimize your lamination stack for maximum performance.

Looking for a manufacturing partner?

Ready to elevate your motor performance with custom Hiperco 50 lamination stacks? Whether you have a detailed design drawing or need help optimizing your core design, our team is here to assist. As your trusted Hiperco 50 lamination stack manufacturer, we’re committed to delivering solutions that meet your unique needs and exceed your expectations.

Request a Technical ConsultationContact us now to discuss your project, request a free quote, or learn more about how our custom Hiperco 50 lamination stacks can transform your motor design. Let’s build high-performance, energy-efficient motors together—one precision lamination at a time.

About Youyou Technology

Youyou Technology Co., Ltd. specializes in the manufacture of Self-bonding precision cores made of various soft magnetic materials, including Self-bonding silicon steel, ultra-thin silicon steel, and Self-bonding specialty soft magnetic alloys. We utilize advanced manufacturing processes for precision magnetic components, providing advanced solutions for soft magnetic cores used in key power components such as high-performance motors, high-speed motors, medium-frequency transformers, and reactors.

The company Self-bonding precision core products currently include a range of silicon steel cores with strip thicknesses of 0.05mm(ST-050), 0.1mm(10JNEX900/ST-100), 0.15mm, 0.2mm(20JNEH1200/20HX1200/ B20AV1200/20CS1200HF), and 0.35mm(35JNE210/35JNE230/ B35A250-Z/35CS230HF), as well as specialty soft magnetic alloy cores including Hiperco 50 and VACODUR 49 and 1J22 and 1J50.