Key Requirements for High-Performance Linear Motor Laminations

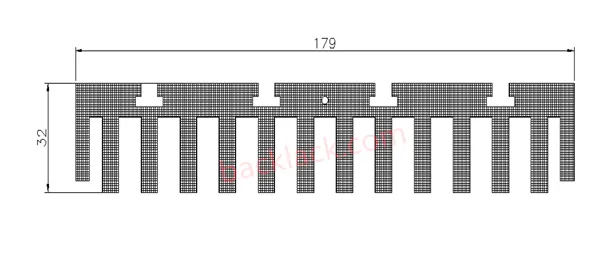

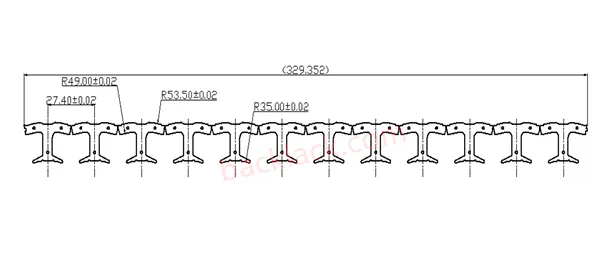

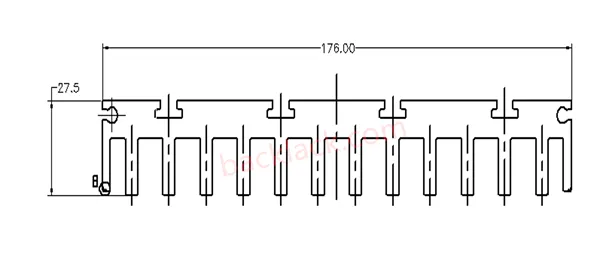

Linear motors differ from traditional rotary motors in their direct-drive design, which demands laminations that can withstand high magnetic flux densities and maintain tight dimensional tolerances. Unlike rotary motor laminations, linear motor cores often have elongated structures and complex slot geometries, requiring stricter manufacturing control. Here are the non-negotiable requirements for top-tier linear motor laminations:

- Superior Magnetic Properties: Laminations must use low-loss electrical steel to minimize eddy current and hysteresis losses, especially critical for high-speed linear motion applications where energy efficiency is paramount.

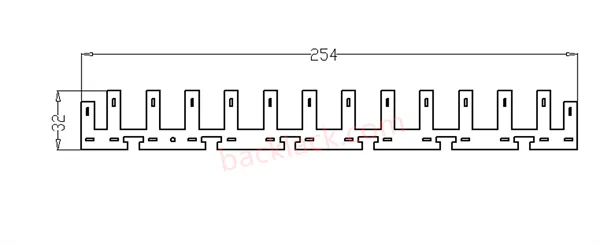

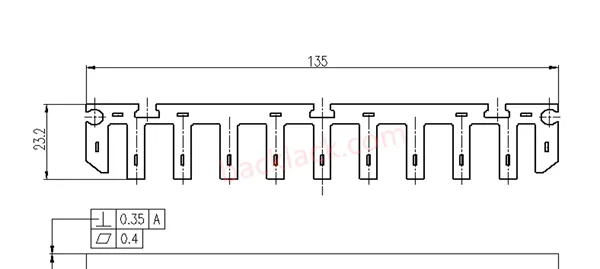

- Precision Dimensional Control: Slot width, tooth thickness, and lamination flatness must be consistent across batches to ensure uniform magnetic fields, avoiding cogging torque and motion instability.

- Robust Lamination Bonding: The stacked core must have strong interlayer adhesion (via welding, riveting, or bonding) to resist vibration and maintain structural integrity under dynamic loads.

- Corrosion & Wear Resistance: For harsh industrial or automotive environments, laminations may require surface treatments to prevent rust and extend service life.

Failing to meet these requirements can lead to costly consequences—from reduced production throughput in automation lines to shortened battery life in EVs. That’s why partnering with a manufacturer that masters these nuances is a strategic investment.

Our Manufacturing Advantages: Crafting Linear Motor Laminations You Can Trust

With over a decade of experience in motor core processing, we’ve refined our workflows to deliver linear motor laminations that exceed industry standards. Here’s how we stand out:

-

Premium Material Sourcing & Pre-Production Testing

We source high-grade non-oriented electrical steel (NOES) from trusted suppliers, including grades like 35W250, 50W470, and custom low-loss alloys for specialized applications. Every batch of raw material undergoes rigorous testing using a magnetic properties tester and spectral analyzer to verify:

Material Test Item Our Standard Industry Average Iron Loss (50Hz, 1.5T) ≤2.5 W/kg ≤3.2 W/kg Magnetic Permeability (μ) ≥1500 μ₀ ≥1200 μ₀ Thickness Tolerance ±0.002 mm ±0.005 mm -

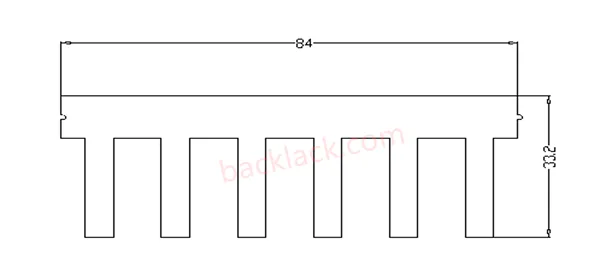

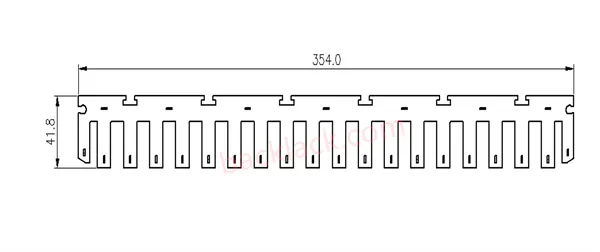

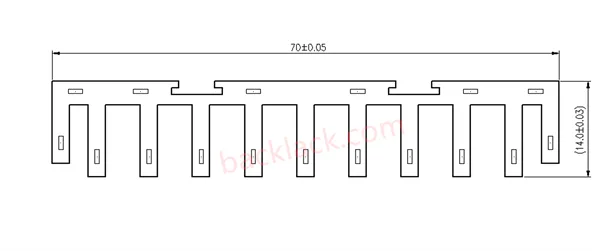

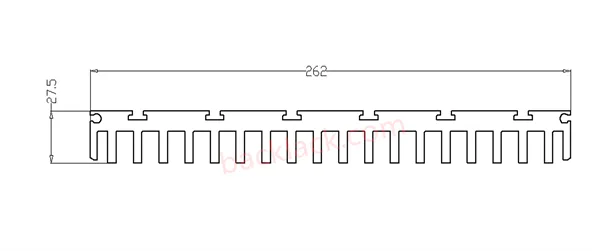

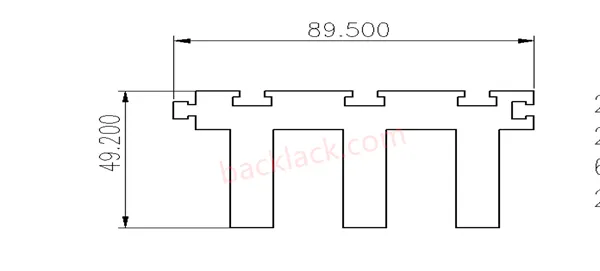

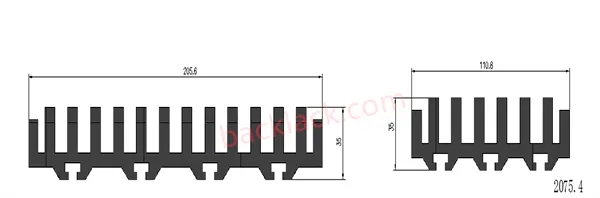

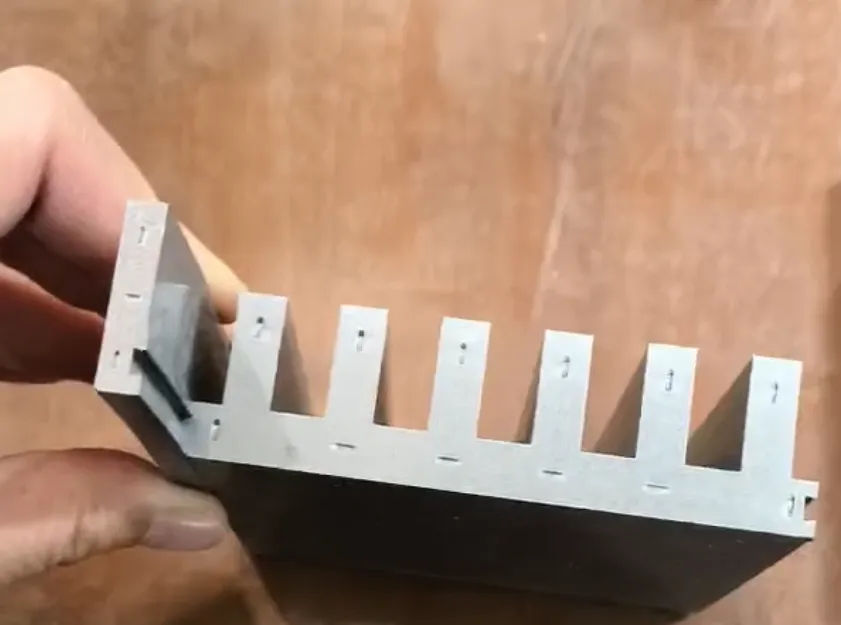

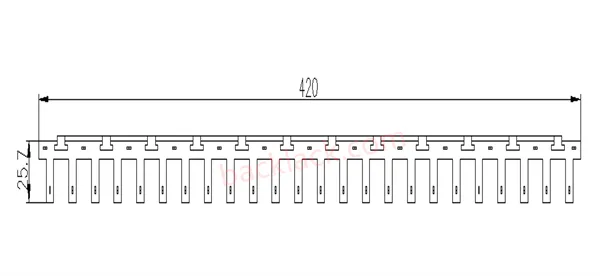

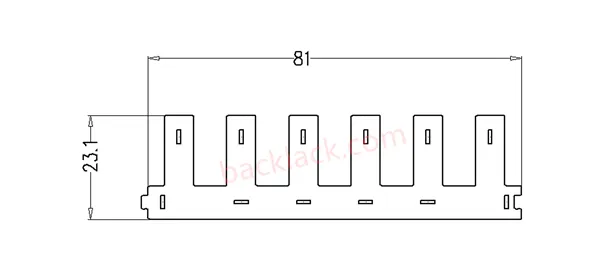

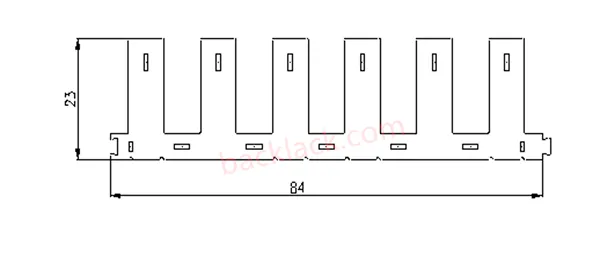

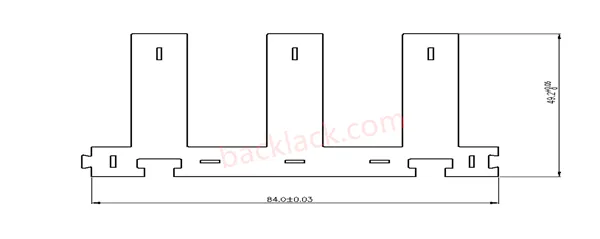

Precision Stamping with Advanced Equipment

Stamping is the most critical step in linear motor lamination production, and we’ve invested in state-of-the-art equipment to master it:

CNC precision stamping presses (200-500 tons) with servo feed systems, enabling stamping accuracy of ±0.003 mm—critical for complex slot designs in linear motor stators.

Progressive die sets custom-designed for each lamination type, allowing simultaneous blanking, slotting, notching, and punching in one pass to ensure dimensional consistency.

Automated burr removal systems that keep burr height below 0.005 mm, preventing short circuits during winding and reducing assembly friction.

We also implement real-time quality checks during stamping, using vision inspection systems to scan 100% of parts for dimensional errors and surface defects.

-

Advanced Lamination & Assembly Techniques

After stamping, we use two primary lamination methods to meet different application needs:

Lamination Method Process Details Advantages Ideal Applications Stack Welding Argon arc welding at 4-6 points per lamination layer, controlled via CNC High structural strength, resistance to high vibration EV powertrains, industrial automation Insulated Bonding Thermal curing of epoxy adhesive between layers Low iron loss, uniform stack density Precision CNC machines, medical robotics All stacked cores undergo flatness testing (≤0.008 mm per 100 mm length) and perpendicularity checks to ensure seamless integration into linear motor assemblies.

-

Fully Customized Solutions for Every Industry

No two linear motor applications are the same, which is why we offer end-to-end customization:

Design Collaboration: Our engineering team works with you to optimize lamination geometry for your motor’s power, speed, and space constraints—using FEA (Finite Element Analysis) to simulate magnetic performance.

Material Customization: We select or source specialty materials (e.g., high-temperature electrical steel for EVs, corrosion-resistant alloys for marine applications) based on your environment.

Volume Flexibility: We handle small-batch prototypes (10-50 units) and large-scale production (10,000+ units per month) with consistent quality.

Value-Added Services: Post-assembly services include winding, varnishing, and final magnetic testing to deliver ready-to-install cores.

Our Linear Motor Laminations in Action: Key Industry Applications

Our customized linear motor laminations power critical systems across industries. Here’s how they deliver value in real-world scenarios:

-

Industrial Automation

For a leading manufacturer of pick-and-place robots, we developed linear motor laminations with optimized slot design to reduce cogging torque by 35%. The result: faster cycle times (from 0.8s to 0.5s per pick) and a 15% increase in production throughput. Key specs:

Stamping accuracy: ±0.002 mm

Stack height: 80 mm (tolerance ±0.1 mm)

Material: B35A230/35W230 electrical steel

-

Electric Vehicles (EVs)

We supplied high-temperature resistant linear motor laminations for an EV manufacturer’s battery cooling systems. The laminations use 50W470 electrical steel with a silicone coating, enabling operation at 150°C (vs. the industry standard 120°C). This improved cooling efficiency by 20%, extending battery life by 8%.

-

Medical Robotics

For a surgical robot developer, we created low-noise linear motor laminations using insulated bonding. The cores produce less than 38 dB of noise during operation—critical for sterile, low-distraction operating rooms. The laminations also meet Class 100 cleanroom standards.

Case Study: Boosting Efficiency for a Solar Panel Manufacturing Line

A solar panel manufacturer was struggling with frequent downtime in their linear motor-driven wafer cutting machines, caused by premature lamination wear. Their existing laminations had inconsistent slot dimensions, leading to uneven magnetic fields and overheating.

Our solution: Custom linear motor laminations with precision stamping (±0.003 mm tolerance) and stack welding for durability. We also optimized the slot geometry to improve magnetic flux distribution. Here’s the impact after 6 months of use:

| Metric | Before Our Laminations | After Our Laminations | Improvement |

|---|---|---|---|

| Machine Downtime | 8 hours/week | 1 hour/week | 87.5% reduction |

| Motor Efficiency | 88% | 95% | 7% increase |

| Wafer Cutting Yield | 95.2% | 99.1% | 3.9 percentage points increase |

| Lamination Service Life | 6 months | 24 months | 300% extension |

Why Choose Us as Your Linear Motor Lamination Partner?

At our motor core processing factory, quality isn’t just a buzzword—it’s embedded in every step of our manufacturing process. We’re proud to offer:

- Fast lead times: 7-10 days for prototypes, 2-4 weeks for mass production.

- Global supply chain capabilities, with shipping to 20+ countries.

- Dedicated after-sales support: Our team provides technical assistance and performance monitoring for all orders.

Looking for a manufacturing partner?

Whether you’re designing a new linear motor for industrial automation, upgrading an EV powertrain, or building precision medical equipment, we have the expertise to deliver laminations that elevate your product’s performance.

Request a Technical ConsultationContact us today to share your linear motor lamination requirements—we’ll provide a free quote and design consultation to help you find the perfect solution.

About Youyou Technology

Youyou Technology Co., Ltd. specializes in the manufacture of Self-bonding precision cores made of various soft magnetic materials, including Self-bonding silicon steel, ultra-thin silicon steel, and Self-bonding specialty soft magnetic alloys. We utilize advanced manufacturing processes for precision magnetic components, providing advanced solutions for soft magnetic cores used in key power components such as high-performance motors, high-speed motors, medium-frequency transformers, and reactors.

The company Self-bonding precision core products currently include a range of silicon steel cores with strip thicknesses of 0.05mm(ST-050), 0.1mm(10JNEX900/ST-100), 0.15mm, 0.2mm(20JNEH1200/20HX1200/ B20AV1200/20CS1200HF), and 0.35mm(35JNE210/35JNE230/ B35A250-Z/35CS230HF), as well as specialty soft magnetic alloy cores including Hiperco 50 and VACODUR 49 and 1J22 and 1J50.