In the rapidly evolving world of electric vehicles (EVs) and high-efficiency motors, self-bonding technology in motor lamination stacks stands out as a game-changer. This innovative approach is revolutionizing how motor laminations are designed and manufactured, offering significant improvements in motor performance and efficiency.

At its core, bonding technology involves unique methods of layering and bonding thin metal sheets to form the core of electric motors.

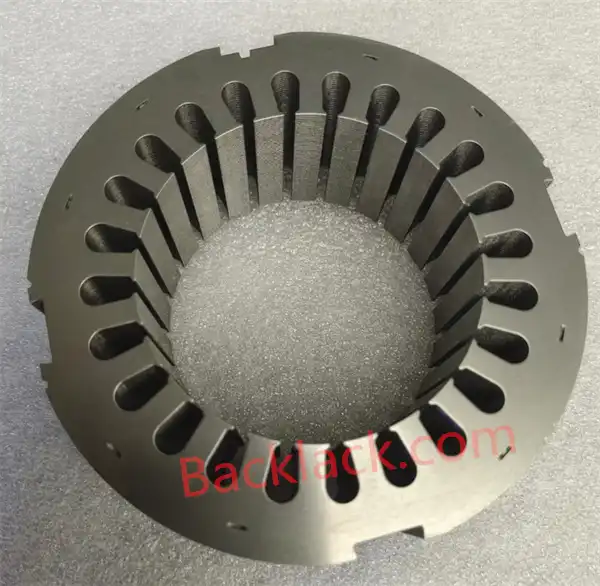

Self-bonding motor lamination stacks represent a key innovation in engineering that fundamentally changes motor design and efficiency. Essentially, these lamination stacks are multiple layers of electrical steel that are fused together without traditional welding or fastening, resulting in a more compact, more efficient motor structure.

This introduction will delve into the mechanics of self-adhesive laminates, highlighting their key role in driving modern technology and engineering practices. Through this blog, we aim to explore the various applications, benefits and emerging trends of this bonding technology, shedding light on its importance across industries and its potential to shape future engineering breakthroughs.

Basic Principles Of Self-Bonding Motor Lamination Stacks

In the field of electric motor manufacturing, self-bonded motor lamination stacks stand out for their unique structure and efficiency-enhancing properties. The core of these lamination stacks consists of multiple layers of electrical steel, which is known for its high magnetic permeability and low iron losses. The self-bonding process generally involves the following steps:

Material Selection

Choosing the right grade of electrical steel is crucial. This material must exhibit excellent magnetic properties and be compatible with the bonding process.

Coating Application

A thin layer of bonding material, often a specialized resin, is applied to the steel sheets. This coating is key to the self-bonding process.

Stacking

The coated sheets are precisely stacked, ensuring alignment for optimal magnetic performance.

Heating and Pressing

The stack is then subjected to heat and pressure. This activates the bonding agent, fusing the layers into a solid, cohesive unit.

Cooling

After bonding, the stack is cooled under controlled conditions to solidify the bond and maintain the desired shape.

This innovative bonding method improves motor performance in several ways. First, it reduces the air gap between laminations, thereby minimizing energy losses due to eddy currents. Second, the absence of traditional fasteners or welds eliminates additional energy losses and mechanical weaknesses. Finally, the streamlined manufacturing process makes the motor not only more efficient, but also more compact and lighter, making it ideal for a wide range of applications where space and weight are key considerations.

Applications In Various Industries

Self-bonding motor lamination stacks have revolutionized multiple industries with their efficiency and performance enhancements.

Aerospace

These laminates have revolutionized the aerospace industry. Aircraft engines, which require high efficiency and reliability, utilize these laminates to improve performance. In addition, other aerospace components also utilize this technology to reduce weight and improve operating efficiency, which is critical to aircraft design.

Industrial Machinery

In the field of industrial machinery, high-performance machines and robots increasingly rely on these lamination packs. They provide the necessary efficiency and durability, which is essential in the demanding environments of industrial applications.

Consumer Electronics

The impact of self-adhesive laminates is also being felt in consumer electronics. Home appliances using these laminates are becoming more energy efficient and reliable, contributing to cost savings and environmental sustainability.

Transportation

In the transportation sector, these laminates play a key role. Electric and hybrid vehicles benefit from their lightweight and efficient properties, which improves battery life and overall vehicle performance. In addition, maglev trains that rely on magnetic levitation are another major application. The precision and efficiency of self-adhesive laminates make a significant contribution to the high-speed and energy-efficient operation of these trains.

Military Applications

The military sector has benefited greatly from these technologies, especially in the aerospace, submarine and specialty vehicle sectors. In these high-stakes environments where performance and reliability are critical, the enhanced durability and efficiency of self-adhesive laminates are essential.

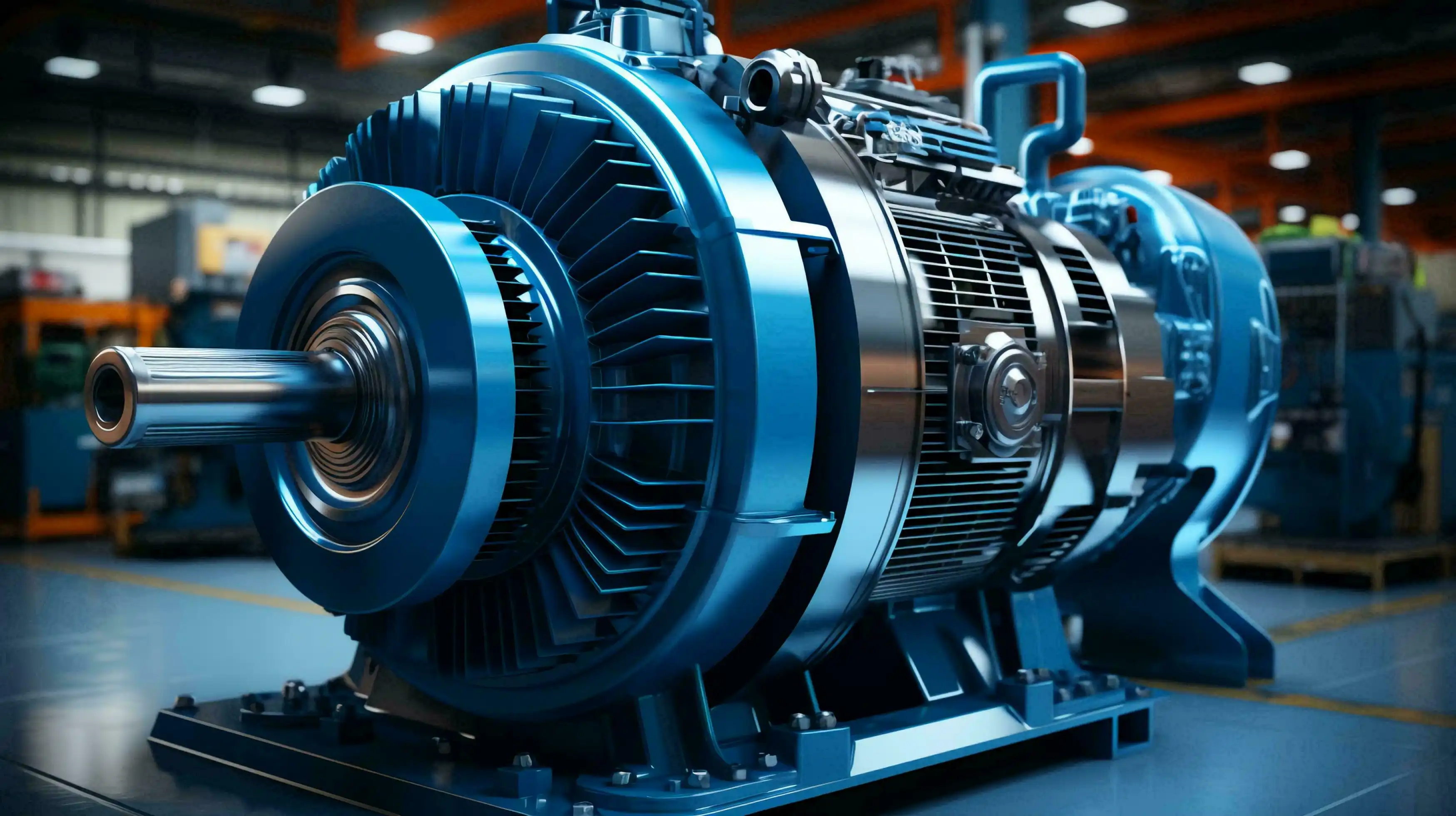

Motor Facilities

Finally, in electromechanical equipment, the use of these battery packs in high-efficiency generators, motors, and transformers represents a significant advance. They improve energy efficiency and operational reliability, which is critical for these applications.

Unmanned Aerial Vehicles (UAVs)

Drones also use these stacks. The need for lightweight, efficient components in drones makes self-adhesive motor stacks ideal for these applications, allowing for longer flight times and increased maneuverability.

Self-bonding motor lamination stacks have revolutionized multiple industries with their efficiency and performance enhancements.

Advantages Of Self-Bonding In Motor Design

Self-bonding in motor design brings a host of advantages, crucial for modern engineering needs.

Increased Efficiency

Foremost, self-bonding significantly boosts energy efficiency. By eliminating air gaps between laminations, it reduces energy losses due to eddy currents. This improvement is vital in applications where energy conservation is paramount, leading to noticeable reductions in operational costs and environmental impact.

Enhanced Durability

Durability is another key benefit. Self-bonding creates a more cohesive and robust motor structure, free from the weaknesses that traditional fastening methods might introduce. This robustness translates into longer lifespans and greater reliability of motors, essential in industries where equipment longevity is critical.

Reduced Size And Weight

The compactness of self-bonded motor laminations is a game-changer, especially in space-constrained applications. The streamlined design results in motors that are not only smaller but also lighter. This reduction in size and weight is particularly beneficial in portable devices and vehicles, where every gram counts towards overall efficiency and performance.

Noise Reduction

Lastly, self-bonding contributes significantly to noise reduction in motor operations. The tight lamination bonds minimize vibration, a common source of noise in motors. This reduction is crucial in consumer electronics and other applications where operational quietness enhances user experience and meets stringent noise regulations.

In summary, the integration of self-bonding in motor design heralds a new era of motor efficiency, durability, compactness, and noise reduction, meeting the evolving demands of modern technology.

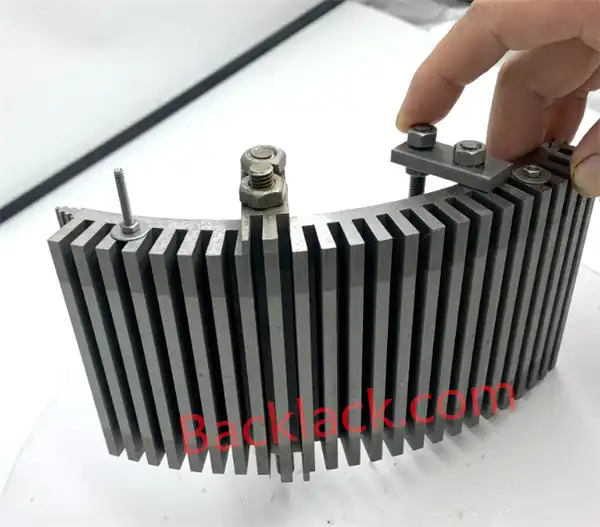

Conventional Stacking Techniques For Electrical Steel Lamination Stacks

Interlocking

Interlocking involves creating tabs and slots on the edges of the laminations, allowing them to snap together without the need for additional bonding agents.

Riveting

Riveting uses mechanical fasteners to hold the laminations together. This method is reliable and easy to implement but can add weight and create stress points within the stack.

Laser Welding

This technique uses a high-powered laser to weld the laminations together at specific points. Laser welding provides a strong bond and precise alignment but can introduce localized heating.

FAQS

What Are The Adhesive Materials Of Self-Bonding Motor Core?

The adhesive materials of self-bonding motor cores are typically EB540, EB546, EB548, EB549, and EB549 fast.

EB549 and EB549 fast are primarily used in new energy vehicle drive motors and small to medium-sized motor cores, providing excellent performance and reliability in these applications.

Applications Of Self-Bonding Motor Laminations

Self-bonding lamination stacks are most commonly used in new energy vehicle motors. They are also ideal for various other applications, including industrial motors, traction motors, renewable energy systems, and high-performance electric motors, offering enhanced efficiency, reduced noise, and improved durability across different sectors.

How Do Self-Bonding Motor Laminates Work?

Lamination bonding represents a groundbreaking advancement in motor manufacturing. Self-bonding motor laminations work through a heat treatment process that activates their bonding properties. When subjected to heat, the laminations bond together at the molecular level, creating a seamless and strong connection.

Can Self Bonding Stack Laminations Be Customized?

Yes, self-bonding motor components can be customized to meet specific requirements and optimal motor performance, such as size, shape, and magnetic properties. This allows for greater flexibility in motor design and optimization.

What Are The Advantages Of Bonding Technology Compared To Other Stacking Methods?

Unlike traditional methods that rely on interlocking or welding points to secure laminations, This bonding lamination technology is used to reduce interlaminar loss and corrosion.

Where Is The Bonded Motor Stack Applied?

Bonded motor lamination stacks are applied in various industries and applications due to high efficiency, compact design, and precision. Mainly including electric vehicles, drones, robotics, etc.

How Does Self-Bonding Differ From Traditional Adhesive Bonding?

Self-bonding involves integrating adhesive materials into the laminations themselves, enabling bonding to occur during the manufacturing process without the need for additional adhesives. This results in a seamless and durable bond.

Can Bonding Laminations Be Used For Segmented Stators In Electric Motors?

Yes, bonding laminations can be used for segmented stators, providing precise bonding between individual segments to create a unified stator assembly.

What Types Of Motors Can Benefit From Self-Bonding Motor Laminates?

Self-bonding motor laminations can benefit a wide range of motors, including brushless DC motors, permanent magnet synchronous motors, and induction motors, among others.

Can Self Bonding Stack Laminations Be Customized?

Yes, self-bonding motor components can be customized to meet specific requirements and optimal motor performance, such as size, shape, and magnetic properties. This allows for greater flexibility in motor design and optimization.

How Do Self-Bonding Motor Laminates Compare To Conventional Bonding Methods?

The laminations use bonding varnish/backlack to bonded to create a stable core. Unlike traditional methods that rely on interlocking teeth or welding points to secure laminations, This bonding lamination technology is used to reduce interlaminar loss and corrosion.

Enhance Your Motor Efficiency With Our Self-Bonding Laminations!

Ready To Connect With YOUYOU’s Expert Team?

Recommended For You