What is 1J22 Soft Magnetic Alloy?

1J22 is a high-saturation magnetic induction soft magnetic alloy primarily composed of iron (Fe) and cobalt (Co). It belongs to the iron-cobalt-molybdenum (Fe-Co-Mo) family of materials. Its most prominent features are:

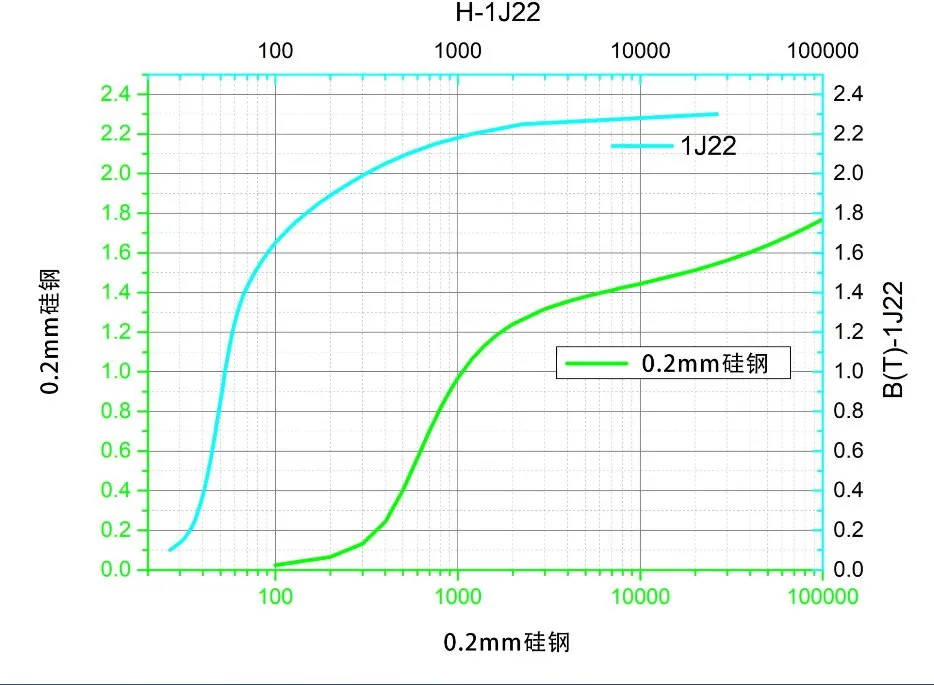

- Extremely high saturation magnetic induction (Bs): It can reach over 2.4T, far exceeding ordinary silicon steel (approximately 2.0T) and most ferrite materials. This means it can carry a stronger magnetic field within the same volume.

- Excellent magnetic permeability: It exhibits high permeability in low and medium magnetic fields, helping to improve motor efficiency and response speed.

- Excellent processability: It can be formed into thin sheets or complex shapes through cold rolling and stamping, making it suitable for precision electromagnetic components.

These properties make 1J22 an ideal choice for aerospace, high-end motors, precision sensors, medical equipment (such as MRIs), and new energy vehicle drive systems.

Challenges of Traditional Silicon Cores

Despite the excellent performance of the 1J22, traditional iron core manufacturing faces numerous challenges:

- High inter-laminar insulation requirements: To reduce eddy current losses, iron cores are typically constructed from hundreds or even thousands of laminated sheets, each of which requires an insulation coating.

- Complex and costly processes: Coating, drying, alignment, and press-fitting are tedious, and yield is controlled by multiple steps.

- Mechanical stress affects magnetic properties: Excessive press-fitting force can reduce the material's magnetic permeability.

Limited space utilization: The insulation layer and press-fitting gaps consume additional space, limiting power density increases.

Self-bonding Cores: An Innovation That Breaks Bottlenecks

It is against this backdrop that self-bonding core technology emerged—providing a new path for the efficient application of high-performance materials like 1J22.

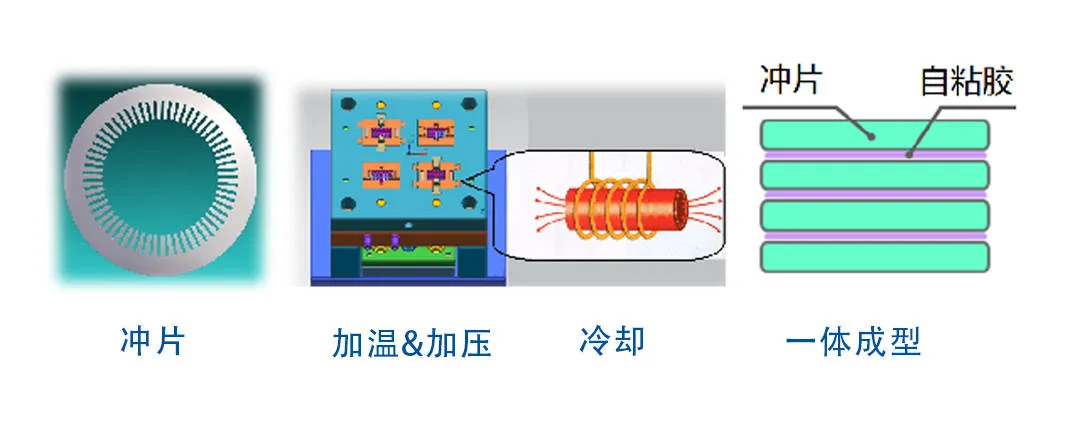

The core principle of self-bonding cores is to apply special surface treatments (such as micro-oxidation, nano-coating, or the introduction of organic/inorganic binders) to the alloy sheets. This allows them to automatically bond to each other after lamination through heating or room-temperature curing, eliminating the need for additional insulating varnish or mechanical fasteners.

Synergistic Advantages of 1J22 + Self-Bonding Technology:

-

Extreme Thinning and High Fill Factor

Thinner 1J22 strip (e.g., less than 0.1mm) can be used. The extremely thin self-bonding layer significantly improves the core's fill factor, packing more magnetic material per unit volume and increasing magnetic flux density.

-

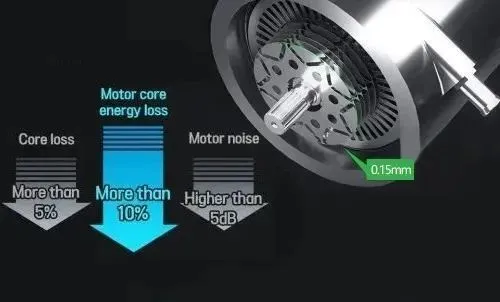

Significantly reduces eddy currents and iron losses.

The self-bonding layer also provides insulation, effectively blocking eddy current paths between laminations. It excels especially under high-frequency conditions, helping the motor achieve ultra-high efficiency.

-

Simplifies manufacturing processes and reduces costs.

Eliminating traditional insulation coating and drying steps shortens production cycles, reduces energy consumption and VOC emissions, and aligns with green manufacturing trends.

-

Strong structural stability

The bonded core offers strong integrity and superior vibration and impact resistance compared to traditional laminated cores, making it suitable for high-speed motors and harsh operating conditions.

-

Increased design freedom

Complex three-dimensional magnetic circuit structures can be realized, supporting customized pole shapes to meet the design requirements of new motors (such as axial flux and harmonic motors).

Application Scenarios: Driving the Future of Power

- New Energy Vehicle Drive Motors: Improve power density and efficiency, extending flight range.

- UAVs and Electric Aviation: Core materials for lightweight, highly responsive motors.

- High-end Industrial Servo Motors: Enable precise control and fast dynamic response.

- Renewable Energy Converters: Ideal for high-frequency transformers and inductors.

Conclusion: A Dual Revolution in Materials and Processes

1J22 soft magnetic alloy itself is a masterpiece of materials science, and self-bonding core technology provides the key to unlocking its full potential. The combination of the two represents more than just a performance boost; it represents a systemic revolution from materials to manufacturing.

The future has arrived, and the "heart" of power systems is becoming smaller, stronger, and smarter. The 1J22 self-bonding core may be the "secret weapon" behind high-efficiency motors, quietly driving humanity towards a green, intelligent, and efficient energy era.

About Youyou Technology

Youyou Technology Co., Ltd. specializes in the manufacture of Self-adhesive precision cores made of various soft magnetic materials, including Self-adhesive silicon steel, ultra-thin silicon steel, and Self-adhesive specialty soft magnetic alloys. We utilize advanced manufacturing processes for precision magnetic components, providing advanced solutions for soft magnetic cores used in key power components such as high-performance motors, high-speed motors, medium-frequency transformers, and reactors.

The company Self-adhesive precision core products currently include a range of silicon steel cores with strip thicknesses of 0.05mm(ST-050), 0.1mm(10JNEX900/ST-100), 0.15mm, 0.2mm(20JNEH1200/20HX1200/ B20AV1200/20CS1200HF), and 0.35mm(35JNE210/35JNE230/ B35A250-Z/35CS230HF), as well as specialty soft magnetic alloy cores including Hiperco 50 and VACODUR 49 and 1J22 and 1J50.