Principle of Motor Glue Bonding Lamination Stack Technology

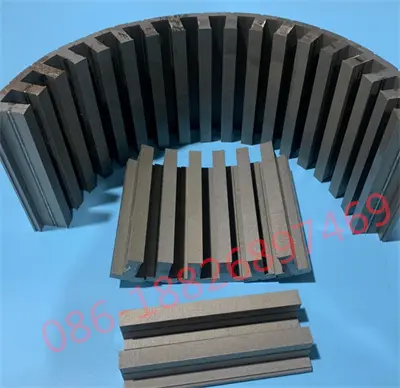

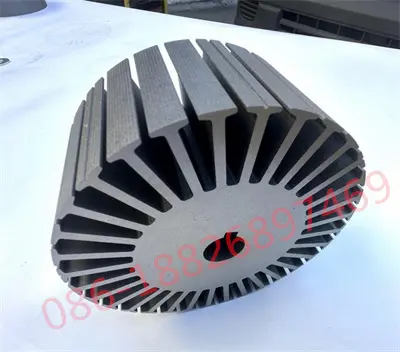

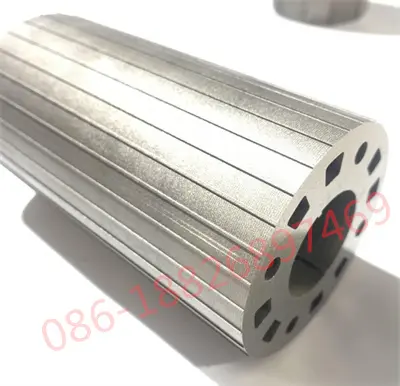

Motor glue bonding lamination stack technology is a manufacturing process that uses high-performance glue to bond and press silicon steel sheets layer by layer, ultimately forming a sturdy and flat lamination stack. This technology combines the advantages of traditional mechanical connections and chemical bonding, ensuring close contact between laminations while improving overall mechanical strength and durability.

Advantages of Motor Glue Bonding Lamination Stack Technology

-

Outstanding Performance Improvement

Through glue bonding, the magnetic flux conduction between silicon steel sheets becomes smoother, thereby significantly improving the energy efficiency and power density of the motor.

-

Excellent Durability

Glue bonding possesses good weather resistance and seismic performance, effectively resisting the impact of various harsh environmental factors and extending the service life of the motor.

-

Significant Noise Reduction

The flat lamination surface greatly reduces the frictional noise and aerodynamic noise during motor operation.

-

Wide Applicability

This technology is applicable to various types of motors, including DC motors, AC motors, stepper motors, etc., meeting the needs of different application scenarios.

-

Environmental Protection and Sustainability

Using environmentally friendly glue reduces environmental pollution during the production process and aligns with the global trend of sustainable development.

Application Cases of Motor Glue Bonding Lamination Stack Technology

-

New Energy Vehicle Field

In the drive motors of new energy vehicles, glue bonding technology effectively improves the power output and torque performance of the motor, helping new energy vehicles achieve longer range and faster acceleration performance.

-

Home Appliance Industry

In the manufacture of home appliance motors, glue bonding technology not only improves the energy efficiency level of the motor but also reduces operating noise, bringing a more comfortable user experience.

-

Industrial Automation Field

Servo motors in industrial automation equipment require extremely high precision and stability. Glue bonding technology ensures the stability and accuracy of the motor during high-speed operation.

Customized Processing Services for Motor Glue Bonding Lamination Stack Technology

To meet the individual needs of different customers, we provide comprehensive customized processing services for motor glue bonding lamination stack technology. From initial technical consultation to detailed product design, and then to professional manufacturing, we maintain close communication with customers throughout the process to ensure that the final product can meet their stringent requirements. In addition, we also provide comprehensive after-sales service and technical support to ensure the long-term stable development of customers.

Conclusion

TechnologicalThe emergence of motor glue bonding lamination stack technology has brought revolutionary changes to the motor manufacturing industry. It not only improves the performance and efficiency of motors but also contributes to environmental protection and sustainability. Looking ahead, we have reason to believe that with the continuous advancement of science and technology and the continuous emergence of innovations, motor glue bonding lamination stack technology will be widely used in more fields, injecting new vitality into the development of human society.

About Youyou Technology

Youyou Technology Co., Ltd. specializes in the manufacture of backlack precision cores made of various soft magnetic materials, including backlack silicon steel, ultra-thin silicon steel, and backlack specialty soft magnetic alloys. We utilize advanced manufacturing processes for precision magnetic components, providing advanced solutions for soft magnetic cores used in key power components such as high-performance motors, high-speed motors, medium-frequency transformers, and reactors.

The company Self-bonding precision core products currently include a range of silicon steel cores with strip thicknesses of 0.05mm(ST-050), 0.1mm(10JNEX900/ST-100), 0.15mm, 0.2mm(20JNEH1200/20HX1200/ B20AV1200/20CS1200HF), and 0.35mm(35JNE210/35JNE230/ B35A250-Z/35CS230HF), as well as specialty soft magnetic alloy cores including Soft Magnetic Alloy 1J22/1J50/1J79.