First, let's get to know 1J50: It's not just any iron

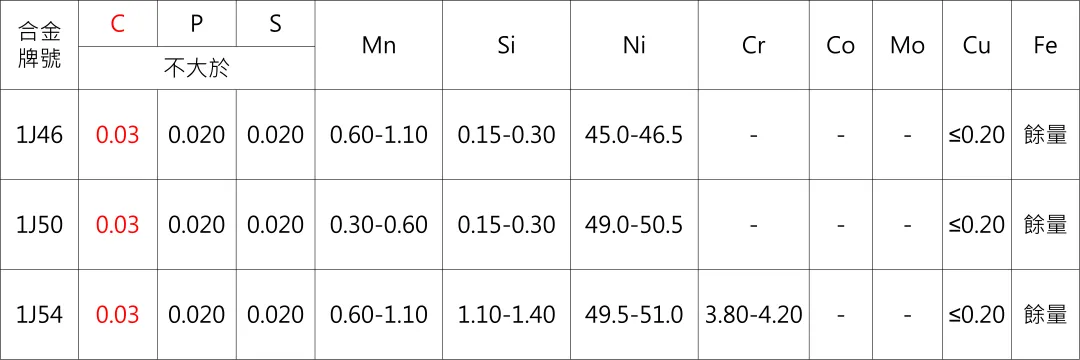

1J50 is an iron-nickel soft magnetic alloy. In domestic standards, the "1" designates soft magnetic properties, the "J" stands for precision, and the "50" indicates a nickel content of approximately 50%. It belongs to the Permalloy family, an elite family of materials known for their high magnetic permeability and low coercivity.

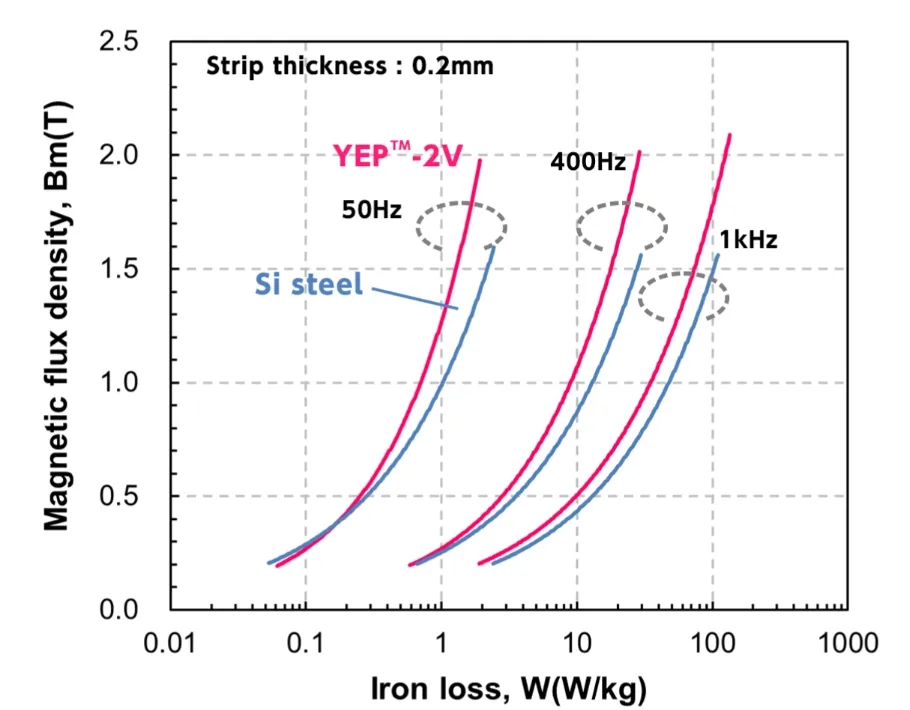

You can think of it as a "superconductor" among magnetic materials (of course, it doesn't have zero resistance, but rather an exceptionally strong ability to conduct magnetic field lines). Compared to ordinary silicon steel sheets (such as DW470), its performance in weak magnetic fields is top-notch.

Five Key Reasons to Choose 1J50

-

Extremely High Saturation Magnetic Induction (Bs)

What is it: Bs is the maximum degree to which a material can be magnetized, determining the strength of the magnetic field it can carry per unit volume.

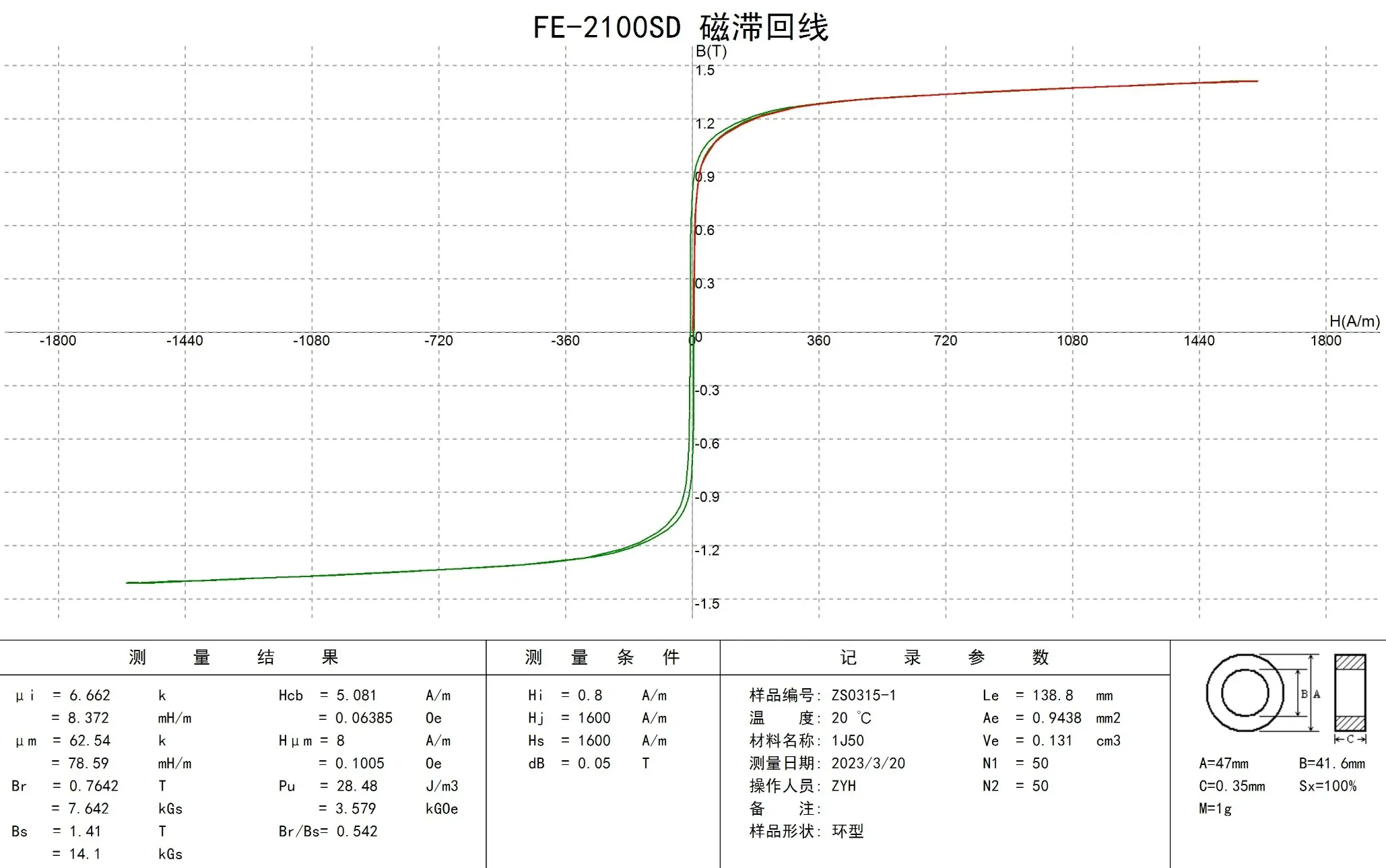

Why is it Important: A high Bs value means that within the same space (stator slots and yoke), the 1J50 can pass a stronger magnetic flux, thereby generating greater torque. This allows for more compact motor designs and high power density. The 1J50's Bs value (approximately 1.5T) is significantly higher than materials like ferrite and comparable to high-grade silicon steel sheets, which is the foundation for its use in power motors.

-

Extremely High Initial Magnetic Permeability (μi) and Maximum Magnetic Permeability (μm)

What is it: Magnetic permeability measures the ease with which a material can be magnetized. The higher the permeability, the lower the excitation current required to establish a magnetic field of the same strength.

Why is it Important: Extremely high magnetic permeability offers two key advantages:

Low excitation current: The current drawn by the motor is very low when it's unloaded or lightly loaded, significantly reducing copper losses (I²R losses) and improving motor efficiency, especially under partially loaded conditions.

High response speed: The magnetic field quickly builds and collapses in response to current changes, giving the motor excellent dynamic response characteristics, making it ideal for applications requiring precise control and fast start-stop times.

-

Extremely Low Coercivity (Hc)

What is it: Coercivity is a measure of a material's resistance to demagnetization. The lower the Hc, the thinner the material's hysteresis loop, making it easier to magnetize and demagnetize.

Why is it Important: Low coercivity directly leads to low hysteresis loss. Hysteresis loss is a significant component of core loss, dissipated as heat. The 1J50's extremely low coercivity minimizes hysteresis loss in alternating magnetic fields, effectively reducing core loss and temperature rise in the motor, thereby improving efficiency and service life.

-

Low Core Loss

Combining these advantages, the 1J50's total core loss (hysteresis loss + eddy current loss) is significantly lower than that of ordinary silicon steel sheets at medium frequencies and flux densities. Although its resistivity is not as high as that of silicon steel, resulting in relatively high eddy current losses at high frequencies, its overall loss performance remains excellent in medium-frequency aviation motors and precision servo motors, which typically operate between 400Hz and 1000Hz.

-

Stable and Consistent Performance

As a "precision alloy," 1J50 undergoes extremely stringent production processes and requirements, ensuring high consistency and stability in its magnetic properties. This is crucial for the mass production of high-performance, high-reliability motors, ensuring that every motor performs as designed.

Trade-offs: 1J50 Disadvantages and Solutions

Of course, no material is perfect, and choosing 1J50 involves trade-offs:

High Cost: The formula, rich in nickel (50%) and molybdenum (approximately 1.8%), makes the raw material cost much higher than silicon steel sheet.

Difficult Processing: 1J50 is a soft material, and punching requires higher tooling and process requirements. More importantly, it must undergo high-temperature hydrogen annealing after processing to relieve stress and restore optimal magnetic properties. This step increases manufacturing cost and complexity.

Limited High-Frequency Applications: Because its resistivity is lower than that of silicon steel, its eddy current losses increase significantly at high frequencies above several thousand Hz, potentially outperforming nanocrystalline, amorphous, or ferrite materials.

Therefore, 1J50 is not used in ordinary household fans or electric vehicle main drive motors (the latter more commonly use silicon steel sheets to balance cost and performance), but is used in fields that have extreme requirements for efficiency, size, weight, response speed and reliability.

Typical Application Scenarios

Aerospace Motors: 400Hz medium-frequency motors in airborne equipment (such as fuel pumps and actuators) have extremely stringent requirements for weight, efficiency, and reliability.

Precision Servo Motors: High-precision CNC machine tools and robotic joints require extremely high control accuracy and fast response.

Military Equipment: High-performance micro motors in radar systems, gyroscopes, and navigation equipment.

High-precision Sensors and Instrumentation: Utilize their high magnetic permeability.

Conclusion

The choice of 1J50 as a motor stator material is essentially a "performance over cost" decision. It trades a high price and complex manufacturing process for unparalleled magnetic properties: high efficiency, low loss, high response, and compact size.

Currently, with technological advances, new materials such as amorphous and nanocrystalline materials are challenging its position. However, in the specific medium-frequency high-performance field, 1J50 remains the irreplaceable "magnetic gold" in the eyes of engineers due to its balanced and stable overall performance.

About Youyou Technology

Youyou Technology Co., Ltd. specializes in the manufacture of Self-bonding precision cores made of various soft magnetic materials, including Self-bonding silicon steel, ultra-thin silicon steel, and Self-bonding specialty soft magnetic alloys. We utilize advanced manufacturing processes for precision magnetic components, providing advanced solutions for soft magnetic cores used in key power components such as high-performance motors, high-speed motors, medium-frequency transformers, and reactors.

The company Self-bonding precision core products currently include a range of silicon steel cores with strip thicknesses of 0.05mm(ST-050), 0.1mm(10JNEX900/ST-100), 0.15mm, 0.2mm(20JNEH1200/20HX1200/ B20AV1200/20CS1200HF), and 0.35mm(35JNE210/35JNE230/ B35A250-Z/35CS230HF), as well as specialty soft magnetic alloy cores including Soft Magnetic Alloy 1J22/1J50/1J79.