Self-adhesive Core Technology

Self-adhesive cores are a novel motor core technology. They utilize a special adhesive applied to the surface of silicon steel sheets, which are then stacked and cured to form a solid, integrated core, replacing traditional mechanical fastening and welding methods. This technology significantly reduces voids within the core, mitigates the effects of magnetic degradation during core processing, and reduces eddy current and hysteresis losses, thereby improving motor efficiency and reliability.

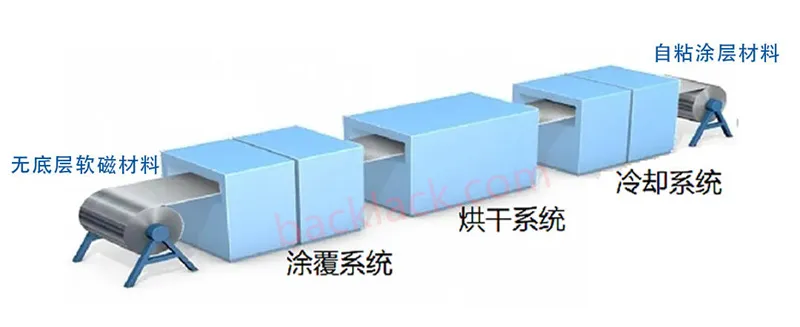

Self-adhesive Core Process

The key to this process lies in the proper selection and application of Self-adhesive coatings, along with strict control, to ensure the quality and stability of the stator core.

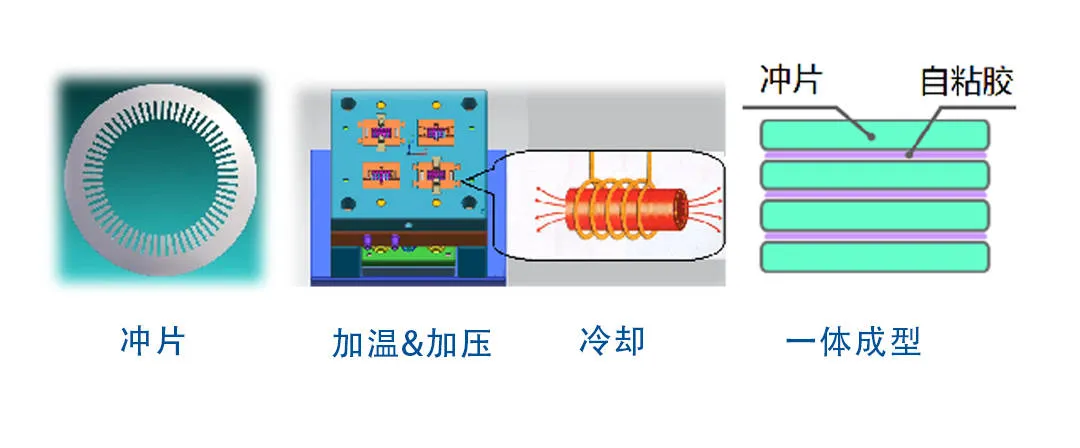

The Self-adhesive core process uses a special coating and high-temperature curing to create a tight bond between the laminations, significantly enhancing the overall structural strength.

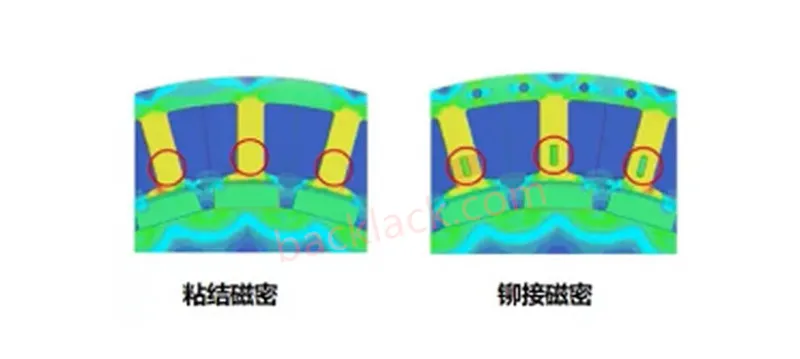

Compared to traditional riveting methods, Self-adhesive cores offer greater stability. They reduce eddy currents and vibration during high-speed rotation, further improving motor efficiency and lowering noise and vibration levels, thereby enhancing overall motor performance.

Self-adhesive cores also reduce the need for fasteners such as end plates and clamping rings, thereby increasing the effective length of the core within the available space.

Technical Difficulties of Self-adhesive Cores

Using ultra-thin silicon steel sheets minimizes iron losses, confining eddy currents to narrow gaps and increasing circuit resistance, thereby reducing eddy currents and iron losses. This is why motors are constructed from laminated thin silicon steel sheets coated with insulating varnish, rather than a single piece of magnetic material.

However, ultra-thin silicon steel sheets are difficult to form riveted joints, and laser welding can cause cracking and uneven stress in the core, negatively impacting motor performance. Therefore, Self-adhesive cores are an ideal solution for assembling ultra-thin silicon steel sheets.

One of the challenges of Self-adhesive cores is ensuring consistent coating thickness on the silicon steel sheets. Furthermore, high requirements for material storage and longevity require sophisticated processing and testing equipment.

Furthermore, the selection of suitable Self-adhesive coating materials requires careful consideration. Youyou Technology has unique advantages in materials, achieving self-sufficiency in thin silicon steel sheets of 0.05-0.15 mm and using materials from Baosteel and Shougang for standard Self-adhesive silicon steel sheets of 0.2 mm and above.

Advantages of Youyou Technology's Self-adhesive Cores

Youyou's Self-adhesive cores, featuring full-surface lamination technology, are suitable for high-speed, high-efficiency motors in various scenarios. They offer irreplaceable advantages in thermal management, core structural strength, temperature resistance, noise, vibration resistance, and design flexibility.

Main Advantages:

- No interlamellar eddy currents: Eliminate the influence of circulating currents throughout the core, further reducing eddy current losses.

- High thermal conductivity: Highly thermally conductive material is used between core layers, enabling rapid heat dissipation and uniform temperature rise.

- Reduced noise: The bonding strength between core layers is far superior to that achieved by processes such as rivet welding, minimizing electromagnetic noise caused by magnetostriction.

- Low core stress: Maximizes material performance without deformation or thermal effects, minimizing performance degradation due to processing.

- Design flexibility: Compatible with core designs with specialized structures, offering flexible machinability.

- Stability: The core operates at temperatures exceeding 200°C, and its resistance to vibration and external forces is far superior to that of other processes. Improved production efficiency: The entire process is fully automated, eliminating manual labor.

- Core miniaturization: Eliminating the need for riveting and welding, the smallest core size is now under 10mm.

Applications of Youyou Technology's Self-adhesive Cores

Youyou's Self-adhesive cores offer significant advantages and are currently being used in a wide range of applications, including aircraft motors, hydrogen fuel cell air compressor motors, drone motors, low-altitude aircraft motors, robotic motors, automotive main drive motors, small appliance motors, magnetic levitation motors, and industrial motors.

About Youyou Technology

Youyou Technology Co., Ltd. specializes in the manufacture of Self-adhesive precision cores made of various soft magnetic materials, including Self-adhesive silicon steel, ultra-thin silicon steel, and Self-adhesive specialty soft magnetic alloys. We utilize advanced manufacturing processes for precision magnetic components, providing advanced solutions for soft magnetic cores used in key power components such as high-performance motors, high-speed motors, medium-frequency transformers, and reactors.

The company Self-adhesive precision core products currently include a range of silicon steel cores with strip thicknesses of 0.05mm(ST-050), 0.1mm(10JNEX900/ST-100), 0.15mm, 0.2mm(20JNEH1200/20HX1200/ B20AV1200/20CS1200HF), and 0.35mm(35JNE210/35JNE230/ B35A250-Z/35CS230HF), as well as specialty soft magnetic alloy cores including Hiperco 50 and VACODUR 49 and 1J22 and 1J50.

Conclusion

As a new technology for improving motor efficiency, Self-adhesive core technology holds broad application prospects and represents a significant development trend. It will drive the motor industry toward greater efficiency, environmental friendliness, and performance, and will be widely applied in even more fields.