Industry application cases

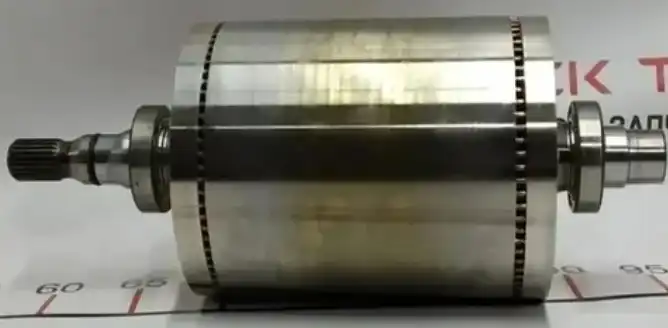

New energy vehicle motor

Tesla's drive motor uses bonding lamination technology to achieve higher torque density and heat dissipation efficiency.

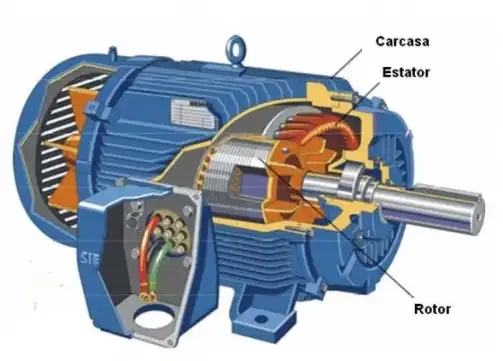

Industrial servo motor

ABB's SynRM (synchronous reluctance motor) reduces iron loss through bonding process and improves energy efficiency to IE5 standard.

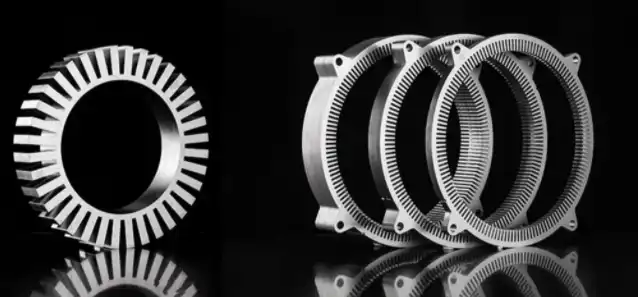

Household appliances

The variable frequency air conditioner compressor motor significantly reduces operating noise due to bonding technology.