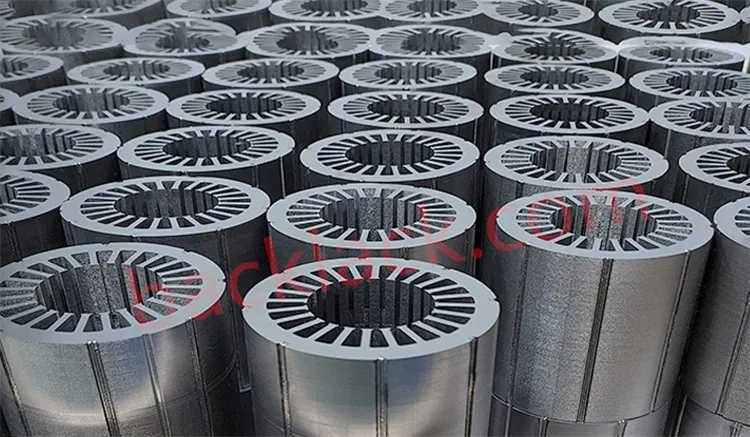

Reduced Eddy Current Losses

Eddy currents are circulating currents induced in conductive materials by changing magnetic fields. These currents generate heat and waste energy, significantly reducing motor efficiency. Stator laminations—thin, insulated silicon steel sheets stacked together—act as barriers to eddy currents. By minimizing the path length for these currents, laminations reduce energy losses by up to 30% compared to solid metal cores. This efficiency boost is crucial for applications like electric vehicles (EVs) and industrial motors, where energy savings translate directly to cost and environmental benefits.

Improved Thermal Management

Heat is a natural byproduct of motor operation, and excessive temperatures can degrade components and reduce lifespan. Stator laminations enhance thermal conductivity, allowing heat to dissipate more effectively. For example, bonded laminations (e.g., laser-welded or adhesive-bonded stacks) eliminate air gaps between layers, improving heat transfer and reducing thermal stress. This feature is vital in high-power applications like HVAC systems and renewable energy generators, where overheating can lead to costly downtime.

Noise and Vibration Reduction

Misaligned or loosely stacked laminations can cause vibrations and audible noise during motor operation. Precision-stacked laminations ensure uniform magnetic flux distribution, minimizing mechanical vibrations. Techniques like interlocking or cleating (using brackets or clips) further stabilize the core, reducing noise by up to 20dB in household appliances like washing machines and refrigerators. This makes laminations indispensable for noise-sensitive environments such as medical equipment or residential HVAC systems.

Enhanced Magnetic Permeability

Silicon steel, the most common lamination material, offers high magnetic permeability, enabling rapid magnetization and demagnetization. This property ensures smooth torque delivery and minimizes hysteresis losses (energy lost during magnetization cycles). For EVs and industrial motors, this translates to higher power density and faster response times.

Cost-Effective and Customizable Design

Laminations allow engineers to tailor motor cores to specific applications. For instance:

- Interlocking stacks are ideal for mass production due to their speed and low labor costs.

- Adhesive bonding suits high-efficiency motors requiring minimal vibration.

- Riveting or bolting secures large-diameter stators for industrial pumps or compressors .

This flexibility enables cost savings in materials, manufacturing, and maintenance.

Extended Durability

By isolating individual laminations, the process prevents corrosion and wear between layers. For example, corrosion-resistant coatings or laser-cut edges enhance longevity in harsh environments like marine propulsion systems or outdoor HVAC units.

Applications Across Industries

Stator laminations are ubiquitous in:

- Electric Vehicles: Enable compact, high-performance motors for extended range.

- Industrial Machinery: Ensure reliability in pumps, compressors, and conveyors.

- Household Appliances: Reduce energy bills and noise in washing machines and air conditioners.

- Renewable Energy: Optimize wind turbine generators and solar inverters.

Conclusion

Motor stator laminations are a cornerstone of efficient, durable, and quiet motor design. From reducing energy waste to enabling compact, high-performance systems, their benefits span efficiency, cost, and sustainability. As industries push for greener technologies, advancements in lamination materials (e.g., amorphous steel) and stacking techniques (e.g., automated precision stacking) will further revolutionize motor engineering.

For manufacturers and engineers, investing in high-quality stator laminations isn’t just a technical choice—it’s a strategic step toward future-ready, energy-efficient solutions.

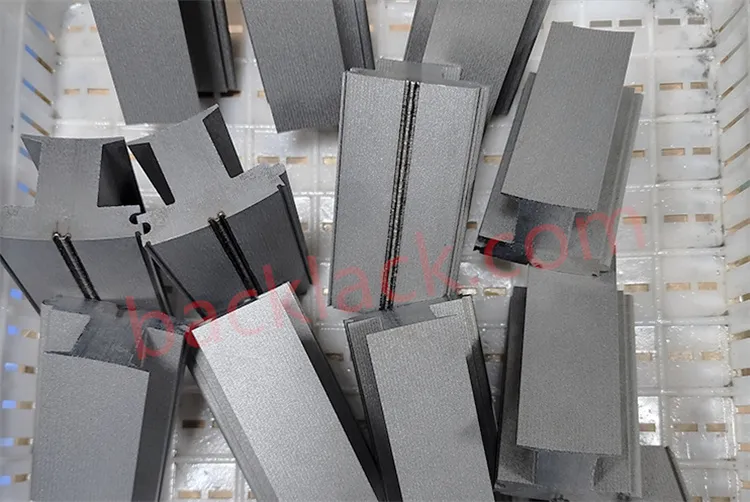

About Youyou Technology

Youyou Technology Co., Ltd. specializes in the manufacture of backlack precision cores made of various soft magnetic materials, including backlack silicon steel, ultra-thin silicon steel, and backlack specialty soft magnetic alloys. We utilize advanced manufacturing processes for precision magnetic components, providing advanced solutions for soft magnetic cores used in key power components such as high-performance motors, high-speed motors, medium-frequency transformers, and reactors.

The company Self-bonding precision core products currently include a range of silicon steel cores with strip thicknesses of 0.05mm(ST-050), 0.1mm(10JNEX900/ST-100), 0.15mm, 0.2mm(20JNEH1200/20HX1200/ B20AV1200/20CS1200HF), and 0.35mm(35JNE210/35JNE230/ B35A250-Z/35CS230HF), as well as specialty soft magnetic alloy cores including Soft Magnetic Alloy 1J22/1J50/1J79.