Thermal Management: The Hidden Key to Motor Performance

When a motor is running, eddy current and hysteresis losses generated in the stator core are converted into heat, causing the temperature to rise. Excessively high operating temperatures can lead to a series of problems:

- Accelerated aging of insulation materials shortens motor life

- Decreased magnetic permeability reduces motor efficiency

- Accumulated thermal stress causes structural deformation and failure

In high-end applications such as electric vehicles and industrial servo systems, heat dissipation has become a major bottleneck hindering the development of high power density and miniaturization in motors.

Adhesive Technology: A Revolution From Structural Fixation To thermal Management

Bonding Process: A Revolution from Structural Fixture to Thermal Management

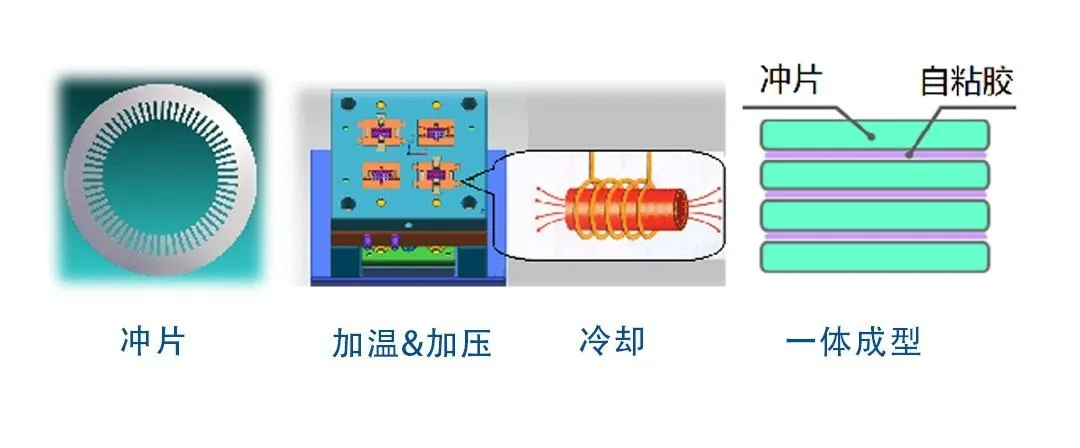

Traditionally, bonding processes were primarily used to secure stator laminations. However, recent research demonstrates that through material innovation and process optimization, bonding can also serve as an excellent heat transfer channel.

Technological Breakthrough

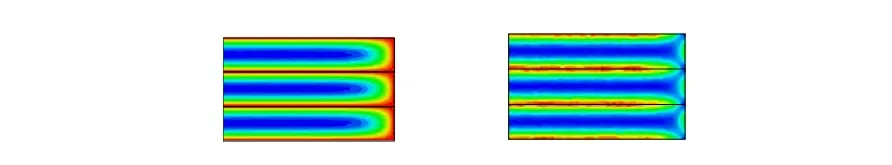

The innovative bonding process creates a continuous, uniform layer of thermally conductive adhesive between the silicon steel laminations, creating an efficient heat dissipation path. This adhesive layer not only secures the laminations but also significantly reduces contact thermal resistance, allowing heat to quickly transfer from the core's interior to the external heat sink.

Material Innovation: The Key to Improving Thermal Conductivity

Choosing the right adhesive is crucial for optimizing core heat dissipation. Advanced thermally conductive adhesives currently on the market offer the following characteristics:

- AcceleratedHigh thermal conductivity: 0.7-1.2 W/m·K, 3-5 times higher than traditional adhesives.

- Low thermal resistance: Optimizes interfacial thermal resistance and enhances heat transfer efficiency.

- Adaptive thermal expansion coefficient: Matches the thermal expansion characteristics of the silicon steel sheet, reducing thermal stress.

- Excellent flow and permeability: Ensures a continuous, bubble-free thermal conductive layer.

In high-end applications such as electric vehicles and industrial servo systems, heat dissipation has become a major bottleneck hindering the development of high power density and miniaturization in motors.

The Influence of Adhesive Process On the Magnetic Circuit of Stator Core

Process Essentials: Key Technical Points for Achieving Excellent Heat Dissipation Performance

-

Precision Glue Application Technology

High-precision automated equipment controls adhesive quantity and application location, ensuring even distribution of adhesive between the laminates and creating a continuous heat conduction path.

-

Curing Process Optimization

A multi-stage temperature profile controls the curing process to prevent air bubbles and internal stress accumulation, ensuring adhesive integrity.

-

Overall Potting

For high-performance applications, overall potting technology is used to encapsulate the entire stator with a highly thermally conductive adhesive, reducing temperature rise by 10-18°C.

Measured Data: Impressive Performance Improvement

The stator core using the optimized gluing process performed exceptionally well in multiple tests:

|

Performance Parameters |

Conventional Process |

Optimized Gluing Process |

Improvement |

|

Thermal Resistance |

1.0 K/W |

0.6 K/W |

40% |

|

Maximum Temperature Rise |

75°C |

52°C |

30.7% |

|

Continuous Power Capacity |

100% |

135% |

35% |

|

Life Expectancy |

10,000 hours |

15,000 hours |

50% |

Application Case: How Industry Leaders Benefit

- Electric Vehicle Drive Motors: A leading electric vehicle manufacturer implemented an optimized adhesive bonding process, resulting in a 32% increase in continuous power output and a 15% weight reduction for its drive motors, directly contributing to increased vehicle range.

- Industrial Servo Systems: A high-end servo motor manufacturer resolved overheating issues under high-load conditions by optimizing its adhesive bonding process, tripling the motor's operating time at rated torque and reducing customer failure rates by 60%.

Self-Bonded Core Helps Reduce Eddy Current Loss and Hysteresis Loss, Improve the Energy Efficiency of the Motor

Future Outlook: Development Trends in Adhesive Heat Dissipation Technology

-

Intelligent Process Control

Integrating AI and machine learning algorithms enables real-time monitoring and adjustment of adhesive process parameters, enabling adaptive optimization and further improving product consistency and performance.

-

Nano-enhanced Materials

Next-generation adhesives incorporating nanoscale thermally conductive fillers (such as boron nitride and graphene) are under development, with the potential to increase thermal conductivity to over 2.0 W/m·K.

-

Integrated Thermal Management

Adhesive processes will be more closely integrated with active cooling technologies such as cooling jackets and heat pipes, forming a multi-layered heat dissipation system to meet the challenges of higher power densities in the future.