1. Strict Raw Material Control: The Foundation of Lean Manufacturing

For our factory, lean core manufacturing is not just a production model, but a systematic project that runs through the entire industrial chain from raw material selection to finished product delivery. We deeply interpret the connotation of lean production, and integrate the concepts of "eliminate waste, continuous improvement" into every link of motor core stamping. In the raw material procurement stage, our factory has built a strict supplier screening and material inspection mechanism — we never compromise on core material quality, and all selections are based on scientific performance comparison to ensure the stability and superiority of incoming materials. The following table shows the specific performance comparison between the high-performance materials we adopt and traditional materials commonly used in the industry:

| Material Type | AC Loss (50Hz, 1.5T) | Residual Magnetism (mT) | Soft Magnetic Performance (High-frequency Adaptability) |

|---|---|---|---|

| High-performance Amorphous Material (Our Choice) | ≤0.3W/kg (1/3 of traditional materials) | ≤50 (1/4 of traditional materials) | Excellent, stable operation at 10kHz+ |

| Traditional Silicon Steel Material | ≥0.9W/kg | ≥200 | General, performance degrades at 5kHz+ |

At the same time, our factory optimizes the procurement and inventory management process through lean thinking, reducing raw material backlogs and capital occupation, and realizing efficient allocation of resources.

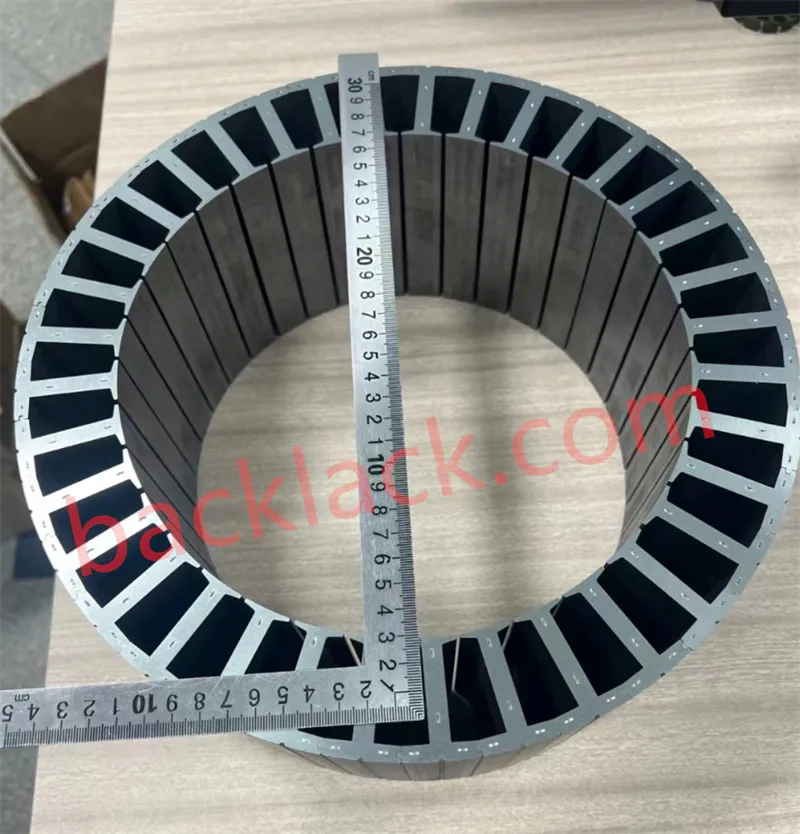

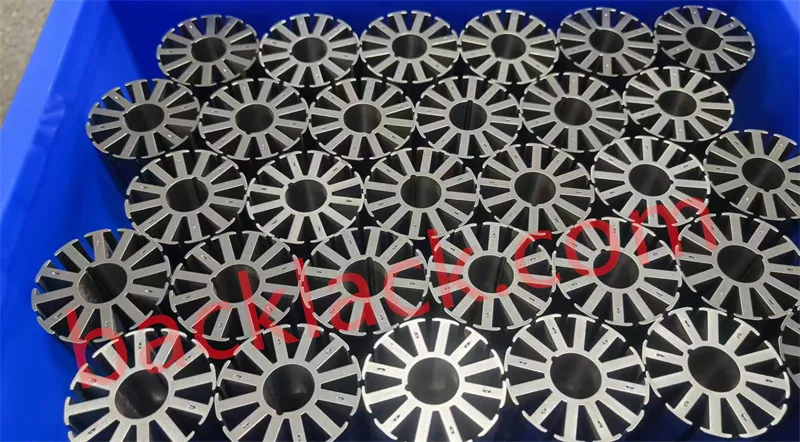

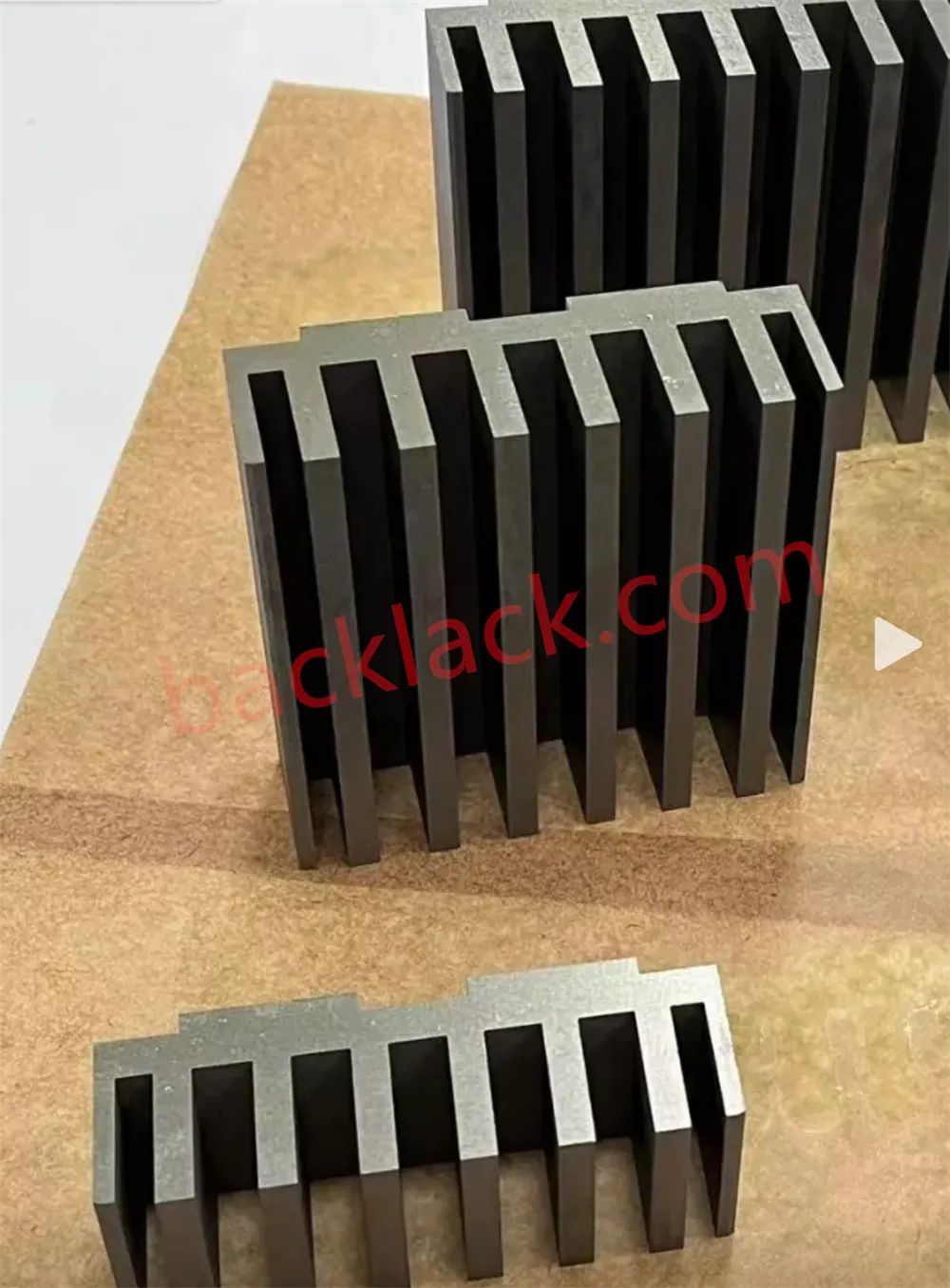

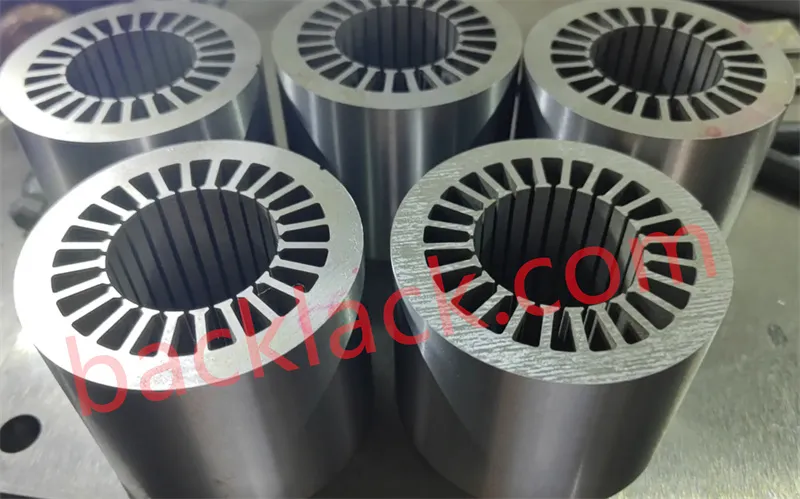

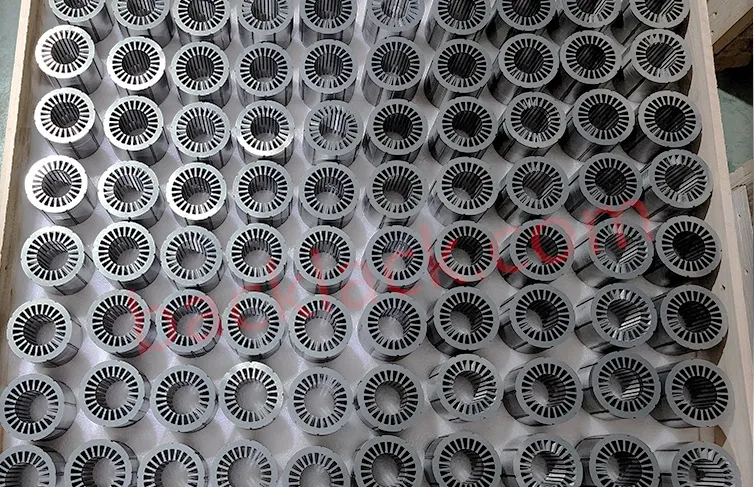

2. Smart Stamping Production: Efficient & Precise Lean Practice

In the core stamping production link, our factory has built a smart production line integrating advanced equipment and intelligent management. Compared with traditional stamping factories, the advantages of our lean production model and high-speed precision stamping technology are clearly reflected in the following specific data:

| Comparison Dimension | Our Factory (Lean/High-speed Precision Mode) | Traditional Stamping Factories (Ordinary Mode)v | Improvement Effect |

|---|---|---|---|

| Production Process Links | 5 streamlined links | 9 redundant links | Processes reduced by 44%, lead time shortened by 30% |

| Production Efficiency | High-speed stamping: 400-1200 times/min (average 800 times/min) | Ordinary stamping: 80-200 times/min (average 140 times/min) | Efficiency increased by 54%+, daily output increased by 471% |

| Dimensional Accuracy & Burr Control | Within IT6 level, burr ≤0.01mm, pass rate 99.8% | IT7-8 level, burr ≤0.05mm, pass rate 95.2% | Precision improved by 2 levels, defect rate reduced by 92% |

| Manufacturing Cost (Per 1000 Pcs) | USD 120 (optimized) | USD 130 (standard) | Cost reduced by 8%, customer procurement cost saved significantly |

To ensure stable production quality, our factory applies lean management tools such as 5S on-site management and Kanban management to standardize every operation detail, reduce human errors, and effectively control the production cycle. Every motor core leaving our factory undergoes strict stamping process parameter monitoring and multi-channel quality inspection, ensuring that its dimensional accuracy, flatness and magnetic performance fully meet your high-standard requirements.

3. Customized Services & One-Stop Process Support

As your reliable process partner, our factory always takes your needs as the core, and provides customized stamping solutions according to your different application scenarios (new energy vehicles, industrial motors, etc.) and technical requirements. Whether you need small-batch, multi-variety customized products or large-batch mass production, we can flexibly adjust the production plan to ensure on-time delivery with zero delay. Our professional technical team has rich experience in motor core stamping — from product design optimization (to improve stamping feasibility) to process plan formulation, from mold development and debugging to after-sales technical support, we provide you with one-stop professional services. We will take the initiative to communicate with you deeply, understand your pain points in production and cost control needs, and work with you to solve technical problems in the process, helping you improve product competitiveness and reduce production costs.

4. Global Service Network & Strict Quality Certification

To drive global customers’ development, our factory has established a sound global sales and service network, providing timely and efficient pre-sales consultation and after-sales support to customers in Europe, America, Asia and other regions. We strictly abide by international quality standards and relevant industry regulations, and have passed ISO9001 quality management system certification and IATF16949 automotive industry quality certification, laying a solid foundation for our products to enter the global market. In the context of global low-carbon development, our factory also actively responds to the call of environmental protection, continuously optimizes the stamping production process, reduces energy consumption by 15% compared with the industry average, reduces waste discharge, and contributes to the sustainable development of the global motor industry together with you.

5. Uninterrupted Pursuit of Lean Manufacturing

For our factory, the road of lean core manufacturing is endless. We will always adhere to the spirit of continuous improvement, keep up with the pace of technological development, continuously introduce advanced stamping production technology and intelligent equipment, and upgrade our lean management level. We firmly believe that with our professional stamping strength, rigorous quality control attitude and sincere service concept, we will become a more reliable process partner for you, work together to promote the innovation and development of the motor industry, and contribute more power to your global market expansion and industrial upgrading.

6. Invitation to Cooperate Hand in Hand

If you are looking for a motor core stamping factory with mature lean production capabilities, reliable product quality, transparent cost control and professional one-stop service, please contact us. Let our factory and your enterprise work hand in hand to create a better future for the global motor industry!

About Youyou Technology

Youyou Technology Co., Ltd. specializes in the manufacture of Self-bonding precision cores made of various soft magnetic materials, including Self-bonding silicon steel, ultra-thin silicon steel, and Self-bonding specialty soft magnetic alloys. We utilize advanced manufacturing processes for precision magnetic components, providing advanced solutions for soft magnetic cores used in key power components such as high-performance motors, high-speed motors, medium-frequency transformers, and reactors.

The company Self-bonding precision core products currently include a range of silicon steel cores with strip thicknesses of 0.05mm(ST-050), 0.1mm(10JNEX900/ST-100), 0.15mm, 0.2mm(20JNEH1200/20HX1200/ B20AV1200/20CS1200HF), and 0.35mm(35JNE210/35JNE230/ B35A250-Z/35CS230HF), as well as specialty soft magnetic alloy cores including Hiperco 50 and VACODUR 49 and 1J22 and 1J50.