Exploration of technical concepts and principles

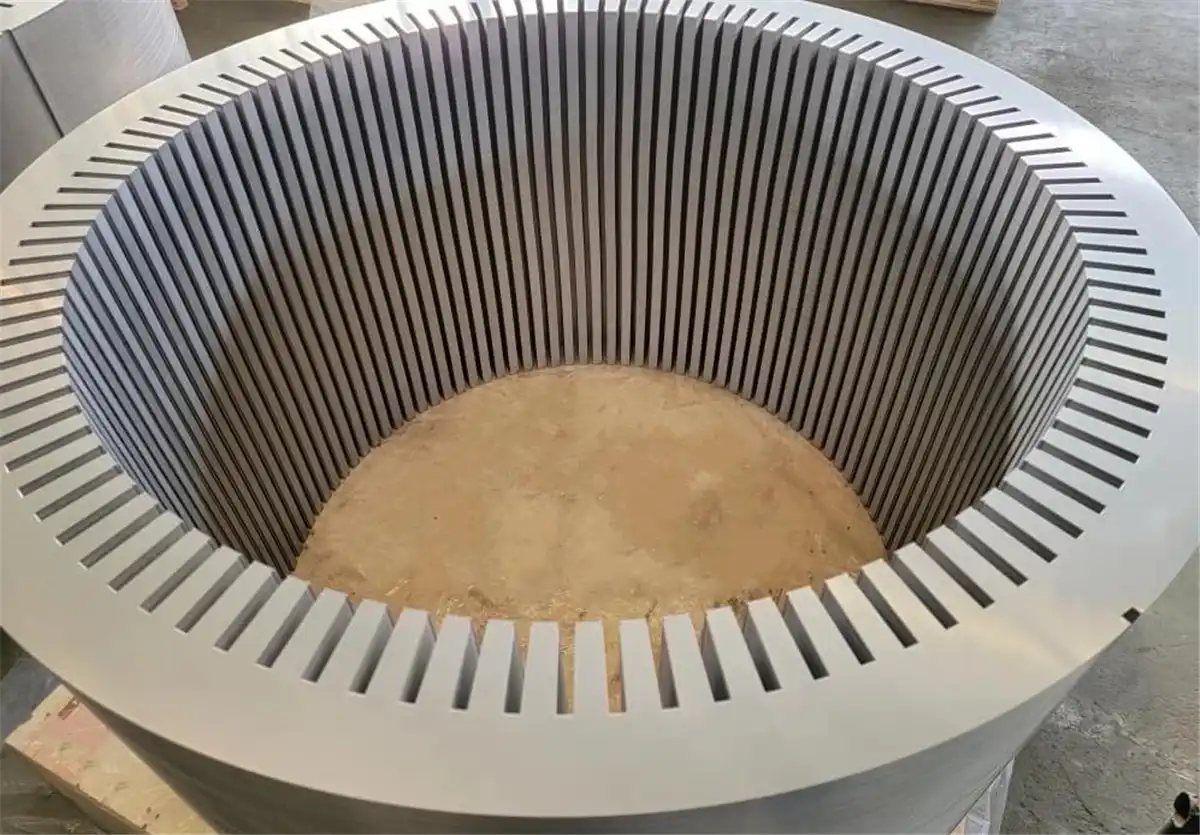

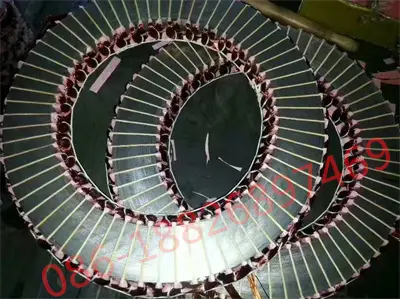

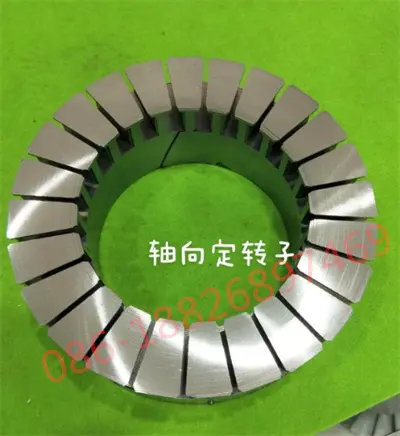

Traditional electric vehicle motors mostly adopt a radial flux design, with the direction of the magnetic field perpendicular to the axis of rotation. In contrast, axial flux motors shorten the magnetic path by adjusting the direction of the magnetic field to be parallel to the axis of the motor. This change greatly increases the power density of the motor. On this basis, the axial flux dual-rotor single-stator motor adopts an innovative dual-rotor layout and a single shared stator design. This design not only optimizes the structure of the motor, but also brings unprecedented performance improvements.

Technical advantages and application value

-

Excellent energy efficiency and power density

The axial flux design shortens the magnetic field path and reduces energy loss. Together with the extra torque output brought by the dual-rotor structure, the motor can provide higher power in a smaller volume. output, greatly improving the endurance and acceleration performance of electric vehicles.

-

Optimized thermal management and heat dissipation

-

Low noise and vibration

Through careful design of the motor structure, the noise and vibration generated by the axial flux dual-rotor motor during operation are much lower than that of traditional motors, providing passengers with a quieter and more comfortable driving experience./p>

-

Simplified structure and easy maintenance

Although the design is novel, it simplifies the mechanical structure, reduces potential failure points, facilitates maintenance and upgrades, and brings convenience to the long-term use and maintenance of electric vehicles.

Challenges faced and coping strategies

Although the axial flux dual-rotor single-stator motor exhibits many advantages, its commercialization path still faces multiple challenges:

-

Cost control

The application of new materials and the demand for precision manufacturing technology have increased production costs, and costs need to be reduced through technological innovation and large-scale production.

-

Design and manufacturing difficulty

High-precision magnet arrangement, complex winding design and strict thermal management requirements place higher demands on the processing technology, which requires continuous optimization of the design process and the adoption of advanced manufacturing technology.

-

System integration and control

The dual-rotor design poses new challenges to the motor control algorithm, requiring the development of an adaptable and responsive control system.

Future Outlook and Industry Impact

Facing the challenges, the future development of axial flux dual-rotor single-stator motors is promising. With the advancement of material science, the maturity of smart manufacturing technology, and the optimization of control strategies, its cost-effectiveness will gradually become apparent, and market acceptance will also increase.

-

Technology maturity and cost reduction

As technology matures and production scale expands, manufacturing costs will gradually decrease, making this technology more popular.

-

Cross-field applications

In addition to electric vehicles, the high efficiency characteristics of axial flux motors also show great potential in aerospace, ship propulsion, industrial equipment and other fields.

-

Promote changes in the industrial chain

The application of new technologies will promote collaborative innovation in the upstream and downstream industrial chains, including material suppliers, equipment manufacturers, software developers, etc., and jointly promote technological progress in the entire electric vehicle industry.

Conclusion

In short, as a major innovation in the power system of electric vehicles, the axial flux dual-rotor single-stator motor not only heralds the future trend of motor technology, but is also an important promoter of electric vehicles and even the entire energy transformation era. With the continuous breakthroughs in technology and the widespread promotion of applications, we have reason to believe that a more efficient, cleaner, and smart mobility era is accelerating.

About Youyou Technology

Youyou Technology Co., Ltd. specializes in the manufacture of backlack precision cores made of various soft magnetic materials, including backlack silicon steel, ultra-thin silicon steel, and backlack specialty soft magnetic alloys. We utilize advanced manufacturing processes for precision magnetic components, providing advanced solutions for soft magnetic cores used in key power components such as high-performance motors, high-speed motors, medium-frequency transformers, and reactors.

The company Self-bonding precision core products currently include a range of silicon steel cores with strip thicknesses of 0.05mm(ST-050), 0.1mm(10JNEX900/ST-100), 0.15mm, 0.2mm(20JNEH1200/20HX1200/ B20AV1200/20CS1200HF), and 0.35mm(35JNE210/35JNE230/ B35A250-Z/35CS230HF), as well as specialty soft magnetic alloy cores including Soft Magnetic Alloy 1J22/1J50/1J79.