I. Four Core Competitive Advantages of Ultra-Thin Self-Adhesive Cores

Compared to traditional mechanical connections, self-adhesive cores achieve tight layer-to-layer bonding through specialized adhesive curing under high temperature and pressure, bringing comprehensive performance leaps to motors.

1. Extreme High-Speed Adaptability and Mechanical Strength (Strength & Speed)

- Advantage: The core forms a quasi-integral structure, with interlayer bonding strength typically reaching 5-20MPa. This significantly enhances overall rigidity and mechanical strength.

- Analysis: EV motors are pushing toward extreme speeds of 20,000 RPM and higher. Traditional cores risk lamination expansion, deformation, or "bursting" under immense centrifugal force. Self-adhesive technology ensures structural stability during ultra-high-speed operation, completely eliminating the risk of Stator Rubbing, and serving as the foundation for high-speed motor reliability.

2. Significantly Reduced Iron Loss, Breaking Efficiency Limits (Efficiency & Iron Loss)

- Advantage: Completely eliminates mechanical stress damage and heat-affected zones on the silicon steel's magnetic properties caused by traditional riveting and welding.

- Analysis: The electromagnetic performance of silicon steel is highly sensitive to stress. Riveting and welding processes disrupt the magnetic domain structure, causing increased localized Eddy Current and Hysteresis Losses. Self-adhesive technology uses physical bonding to maximize the retention of the low-loss characteristics of ultra-thin, high-grade silicon steel (e.g., 0.1/0.2mm and below), resulting in more efficient operation in alternating magnetic fields, directly boosting motor efficiency and EV range.

3. Superior NVH Performance for "Silent" Driving (Noise, Vibration, Harshness)

- Advantage: The adhesive layer acts as a damping element, effectively suppressing minute movement and vibration between laminations.

- Analysis: Electromagnetic forces cause core vibration during motor operation, a major source of noise. The self-adhesive coating acts like a dampening pad, filling minute gaps and absorbing/buffering vibration energy. This drastically reduces operating noise, especially enhancing the quiet and tranquil experience of EV driving.

4. Improved Thermal Uniformity and Stability (Thermal Performance)

- Advantage: The cured adhesive layer provides a more efficient heat conduction path than air.

- Analysis: Traditional cores have tiny air gaps, and air is a poor heat conductor. The self-adhesive coating establishes an efficient thermal bridge, allowing heat generated inside the core (especially the teeth) to be conducted more quickly and uniformly to the casing, improving the motor's continuous power output capability and preventing local hotspots.

II. Industry-Leading Technology: High-Precision In-Die Gluing

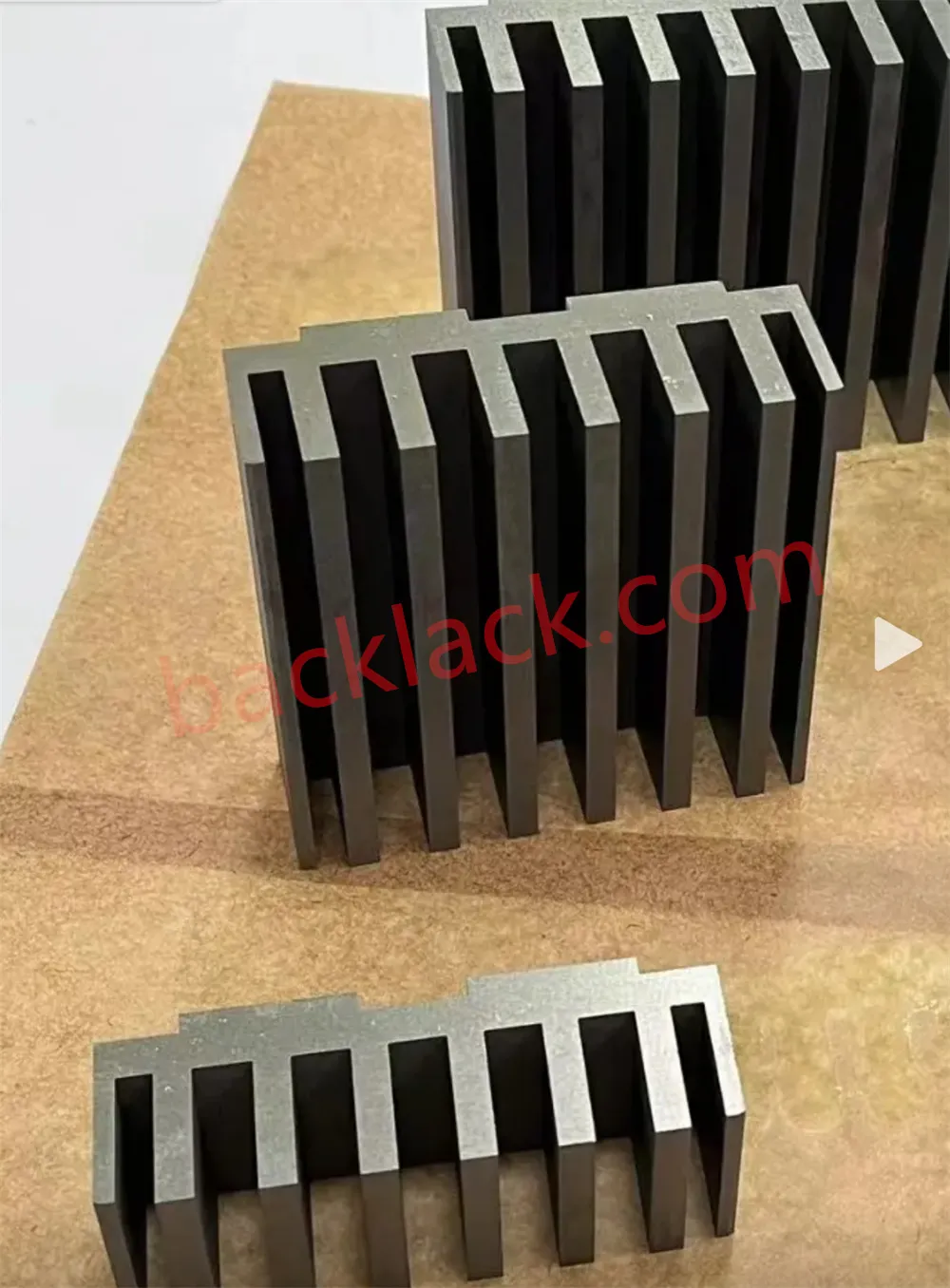

To ensure the top-tier performance and mass production consistency of bonded cores, the manufacturing process is crucial. We have adopted world-class In-Die Gluing technology, setting a new industry benchmark.

**[Patented Technology Advantages]** In-Die Gluing is a revolutionary process: Utilizing specialized dispensing equipment and molds, glue is precisely applied to specified locations on the silicon steel sheet simultaneous with high-speed stamping. We focus on:

- High-Precision Control: Prevents glue overflow, ensuring lamination insulation and magnetic integrity.

- Enhanced Tooth Bonding: Patented technology allows for gluing on the teeth, even **dual-point gluing**, significantly increasing the tooth stiffness required for motor winding processes.

- Production Efficiency: The gluing process is synchronized with stamping, greatly reducing cycle time for efficient mass production and cost control.

III. Technology Comparison: Self-Adhesive Core vs. Traditional Core

| Comparison Metric | Traditional Silicon Steel (Riveting/Welding) | Ultra-Thin Self-Adhesive/Bonded Core |

|---|---|---|

| **Mechanical Strength** | Fair, prone to expansion at high speed | **Excellent**, quasi-integral structure, suitable for 20000+ RPM |

| **Iron Loss/Efficiency** | Highly affected by processing stress, increased losses | **Very Low**, magnetic properties maintained, high efficiency |

| **NVH Performance** | Noise from sheet micro-movement | **Superior**, damping reduces noise, tranquil driving experience |

| **Process Complexity** | Requires extra riveting or welding steps after stamping | **Simplified**, direct stacking and single thermal curing after stamping |

| **Applicable Thickness** | Riveting ultra-thin sheets (e.g., 0.1mm) is difficult | **Perfectly Compatible**, designed for ultra-thin silicon steel |

IV. Conclusion and Outlook: Driving Industrial Innovation

The self-adhesive bonded core is the result of a perfect combination of material science and precision manufacturing. Although the material cost is relatively higher, its comprehensive value in terms of high-speed reliability, system efficiency improvement, and NVH optimization makes it an irreplaceable technological choice for high-specification applications like EV drive motors, high-end servo motors, and drone motors.

**Youyou Company** has invested in state-of-the-art equipment such as baking ovens and automated induction heating lines to ensure the mass production capability and quality stability of bonded cores. Moving forward, we will continue to collaborate with top domestic and international steel mills to jointly develop ultra-thin, low-loss, high-flux super motor solutions, providing customers with more efficient and competitive products.

About Youyou Technology

Youyou Technology Co., Ltd. specializes in the manufacture of Self-bonding precision cores made of various soft magnetic materials, including Self-bonding silicon steel, ultra-thin silicon steel, and Self-bonding specialty soft magnetic alloys. We utilize advanced manufacturing processes for precision magnetic components, providing advanced solutions for soft magnetic cores used in key power components such as high-performance motors, high-speed motors, medium-frequency transformers, and reactors.

The company Self-bonding precision core products currently include a range of silicon steel cores with strip thicknesses of 0.05mm(ST-050), 0.1mm(10JNEX900/ST-100), 0.15mm, 0.2mm(20JNEH1200/20HX1200/ B20AV1200/20CS1200HF), and 0.35mm(35JNE210/35JNE230/ B35A250-Z/35CS230HF), as well as specialty soft magnetic alloy cores including Hiperco 50 and VACODUR 49 and 1J22 and 1J50.