- ✅ High Lamination Accuracy · Low Iron Loss

- ✅ Low Noise & Vibration · Stable Working Condition

- ✅ Simplified Process · Short Delivery Time

- ✅ Flexible Customization · Full Coverage

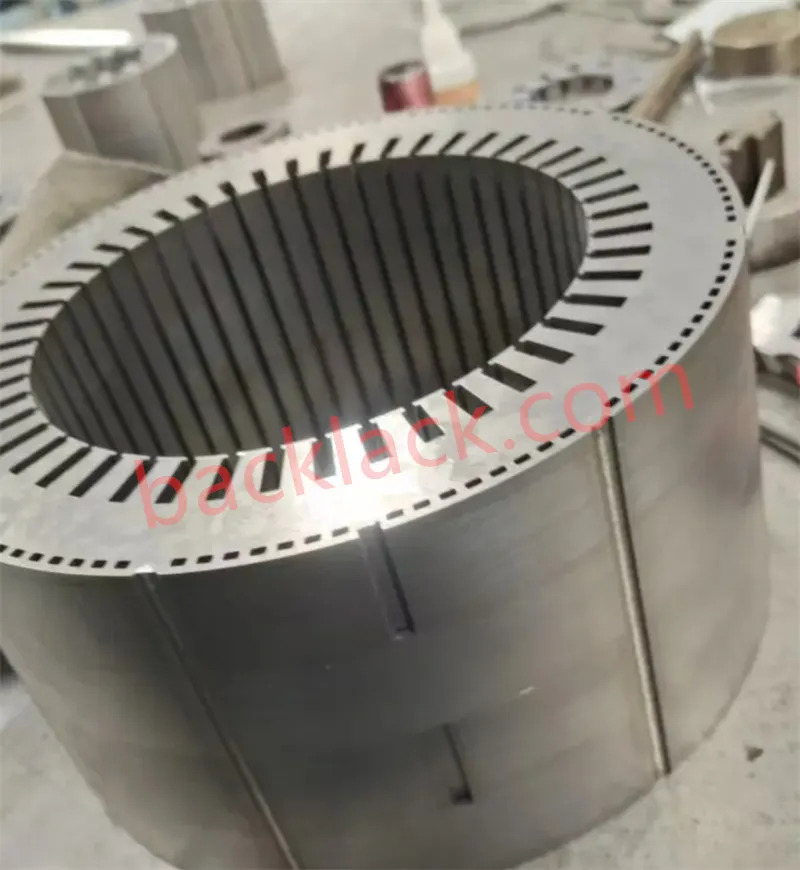

Self-adhesive stator cores adopt an integrated process of in-mold stamping + thermal curing, optimizing the structural design and production process comprehensively to solve many pain points of traditional cores. They have become the preferred core components for high-end motors, serving more than 200 enterprise customers.

1. High Lamination Accuracy + Low Iron Loss, Motor Efficiency Approaches Industry Peak

Traditional stator cores use welding or riveting processes to fix laminations, which inevitably generate mechanical stress, leading to lamination deformation and increased gaps. This not only reduces the lamination factor but also exacerbates iron loss during motor operation, directly affecting motor efficiency. In contrast, the self-adhesive stator cores produced by our factory adopt advanced stamping + thermal curing molding technology. The laminations are closely bonded through special self-adhesive coatings without additional welding or riveting, fundamentally avoiding the defects of traditional processes.

| Comparison Item | Traditional Stator Core | Self-Adhesive Stator Core |

|---|---|---|

| Lamination Factor | 92%-94% | Above 97% |

| Iron Loss Reduction Range | No significant optimization | 15%-20% |

| Process Stress | High mechanical stress | No mechanical stress |

From actual production data, the lamination factor of self-adhesive stator cores can reach above 97%, far exceeding the 92%-94% of traditional cores. Meanwhile, the processing method without mechanical stress maintains the optimal magnetic permeability of silicon steel sheets, reducing iron loss by 15%-20% compared with traditional cores. This means that motors equipped with our self-adhesive stator cores consume less energy at the same power, fully adapting to scenarios with high energy efficiency requirements such as NEVs and energy-saving industrial motors.

2. Low Noise & Vibration, Adapting to the Silent Requirements of High-End Equipment

Motor operating noise and vibration are one of the core pain points of high-end equipment (such as industrial robots, precision CNC machine tools, and EV traction motors), and the root cause of this problem often lies in the stator core. The welding/riveting joints of traditional cores have gaps, which are prone to resonance during high-speed operation, and friction between laminations also exacerbates noise.

| Comparison Item | Traditional Stator Core | Self-Adhesive Stator Core |

|---|---|---|

| Operating Noise | High noise (≥65dB) | Reduced by 8-12dB |

| Vibration Amplitude | Large (≥0.5mm/s) | Reduced by more than 30% |

| Structural Gap | Gaps exist at welding/riveting joints | Seamless bonding of laminations |

Our self-adhesive stator cores are formed by integrated bonding, with laminations closely attached without gaps, fundamentally eliminating resonance and friction noise from the structure. According to actual measurements, the operating noise of high-speed servo motors equipped with self-adhesive stator cores can be reduced by 8-12dB, and the vibration amplitude by more than 30%. At present, we have customized self-adhesive stator cores for multiple industrial robot enterprises, and their silent effect has been highly recognized by customers, becoming a key advantage for their product differentiation competition.

3. Simplified Process + Short Delivery Time, Cost Reduction and Efficiency Improvement Are Visible

As a processing factory, we deeply understand the importance of production efficiency and cost control for customers. The production process of traditional stator cores is cumbersome, requiring multiple procedures, while self-adhesive stator cores achieve process integration, with significant advantages in cost reduction and efficiency improvement.

| Comparison Item | Traditional Stator Core | Self-Adhesive Stator Core |

|---|---|---|

| Production Processes | Multiple processes including stamping, lamination, welding/riveting, grinding, etc. | Integrated stamping + bonding |

| Production Efficiency | Conventional efficiency (100 pieces/day) | Improved by over 40% (140+ pieces/day) |

| Manual Intervention | More (5-8 people/line) | Reduced by 50% (2-4 people/line) |

| Delivery Time | 10-15 days | 3-7 days |

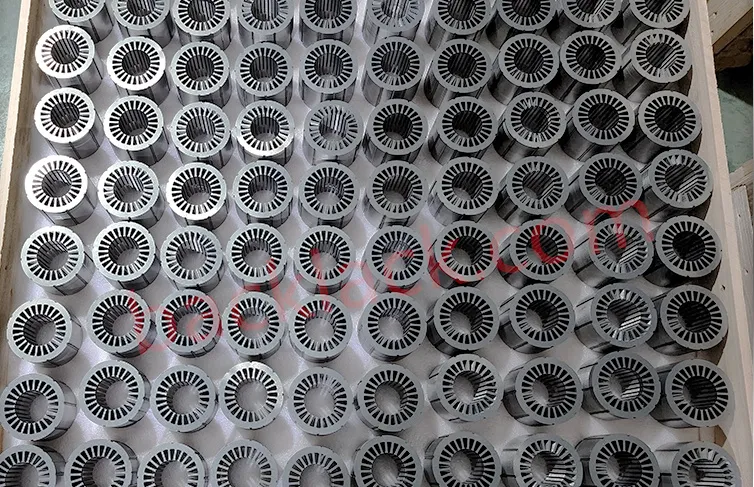

Self-adhesive stator cores realize integrated "stamping + bonding" production. Through an automated stamping production line, we integrate processes such as gluing, stamping, lamination, and curing, improving production efficiency by more than 40% and reducing manual intervention by 50%, greatly lowering human errors. More importantly, the simplified process shortens the product delivery time to 3-7 days (traditional processes require 10-15 days), helping customers respond quickly to market demands. In addition, no additional tooth pressure plates, rivets, or other accessories are needed, further reducing customers' procurement costs.

4. Stable Structure Resistant to Severe Working Conditions, Service Life Greatly Extended

High-end motors often need to operate for a long time under severe working conditions such as high temperature, high speed, and high-frequency start-stop, which puts extremely high requirements on the structural stability and weather resistance of stator cores. The welding points of traditional welded cores are prone to aging and falling off in high-temperature environments, while riveted cores may loosen, seriously affecting the service life of motors.

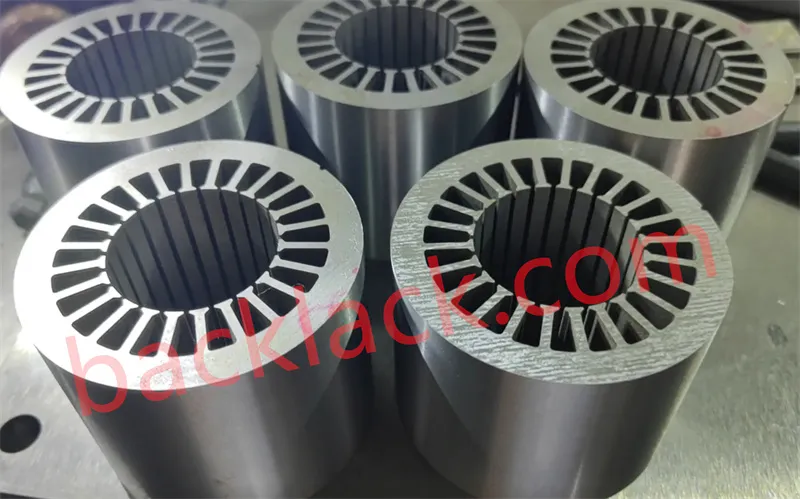

We select high-temperature resistant special self-adhesive coatings, combined with 0.1mm ultra-thin silicon steel sheets. After high-temperature curing, self-adhesive stator cores have excellent performance:

- Bonding strength can reach above 25MPa (equivalent to 2.5 tons per square centimeter)

- Temperature resistance range: -40℃ to 180℃ (covering extreme working conditions)

- Excellent anti-vibration and anti-corrosion performance

- Service life extended by more than 20%

In the long-term test of EV traction motors, motors equipped with our self-adhesive stator cores have maintained good structural stability under continuous high-frequency start-stop (≥100,000 times) and high-temperature operation (120℃) conditions. The maintenance cost is significantly lower than that of motors with traditional cores, winning consistent recognition from customers.

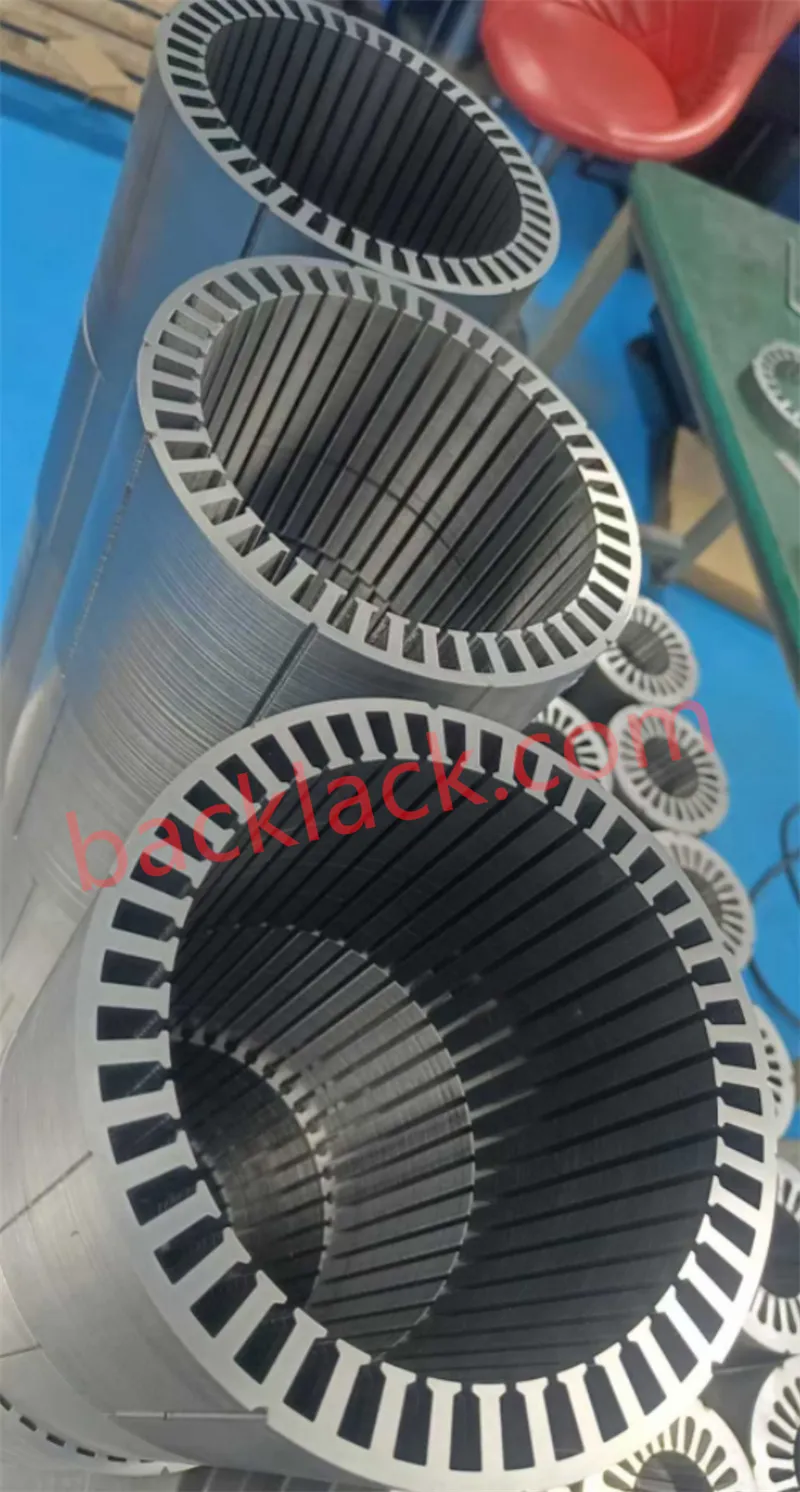

5. Strong Customization Capability, Covering Full-Scenario Motor Requirements

Motors in different industries have vastly different requirements for the size, power, and working conditions of stator cores. The production process of traditional cores is limited by the welding/riveting structure, making customization difficult and costly. In contrast, our self-adhesive stator core production process has higher flexibility, which can customize products of different specifications and shapes according to customer needs, achieving perfect adaptation through precise stamping control and mold design.

Core Customization Range:

- Miniaturized cores for high-speed servo motors (outer diameter ≤50mm)

- High-power cores for EV traction motors (power ≥150kW)

- High-temperature resistant cores for special working conditions (temperature resistance ≥150℃)

- Customized cores with special-shaped structures (non-standard size/shape)

Widely Used Fields:

- New energy vehicles (EV/hybrid vehicle traction motors)

- Industrial robots (joint servo motors)

- Precision machine tools (spindle drive motors)

- Energy-efficient home appliances (inverter air conditioners/washing machine motors)

The qualification rate of customized products is as high as 99.8%

Conclusion

At present, our self-adhesive stator cores have been widely used in multiple fields such as new energy vehicles, industrial robots, precision machine tools, and energy-efficient home appliances, serving more than 200 enterprise customers. The qualification rate of customized products is as high as 99.8%, with a cumulative delivery of over 1 million pieces.

About Youyou Technology

Youyou Technology Co., Ltd. specializes in the manufacture of Self-bonding precision cores made of various soft magnetic materials, including Self-bonding silicon steel, ultra-thin silicon steel, and Self-bonding specialty soft magnetic alloys. We utilize advanced manufacturing processes for precision magnetic components, providing advanced solutions for soft magnetic cores used in key power components such as high-performance motors, high-speed motors, medium-frequency transformers, and reactors.

The company Self-bonding precision core products currently include a range of silicon steel cores with strip thicknesses of 0.05mm(ST-050), 0.1mm(10JNEX900/ST-100), 0.15mm, 0.2mm(20JNEH1200/20HX1200/ B20AV1200/20CS1200HF), and 0.35mm(35JNE210/35JNE230/ B35A250-Z/35CS230HF), as well as specialty soft magnetic alloy cores including Hiperco 50 and VACODUR 49 and 1J22 and 1J50.