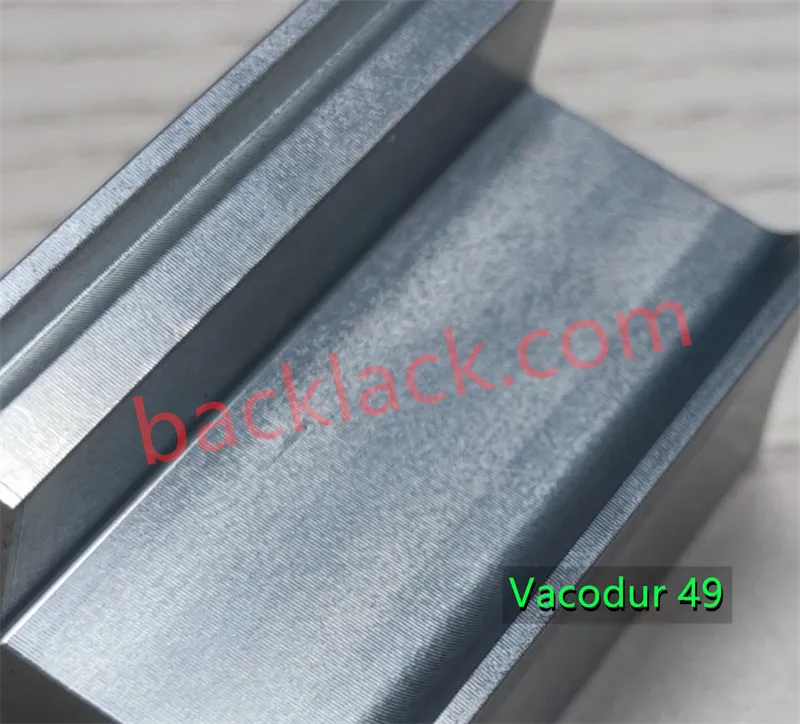

Why VACODUR® 49 Sheet Material Is Ideal for Electric Motor Lamination Stacks

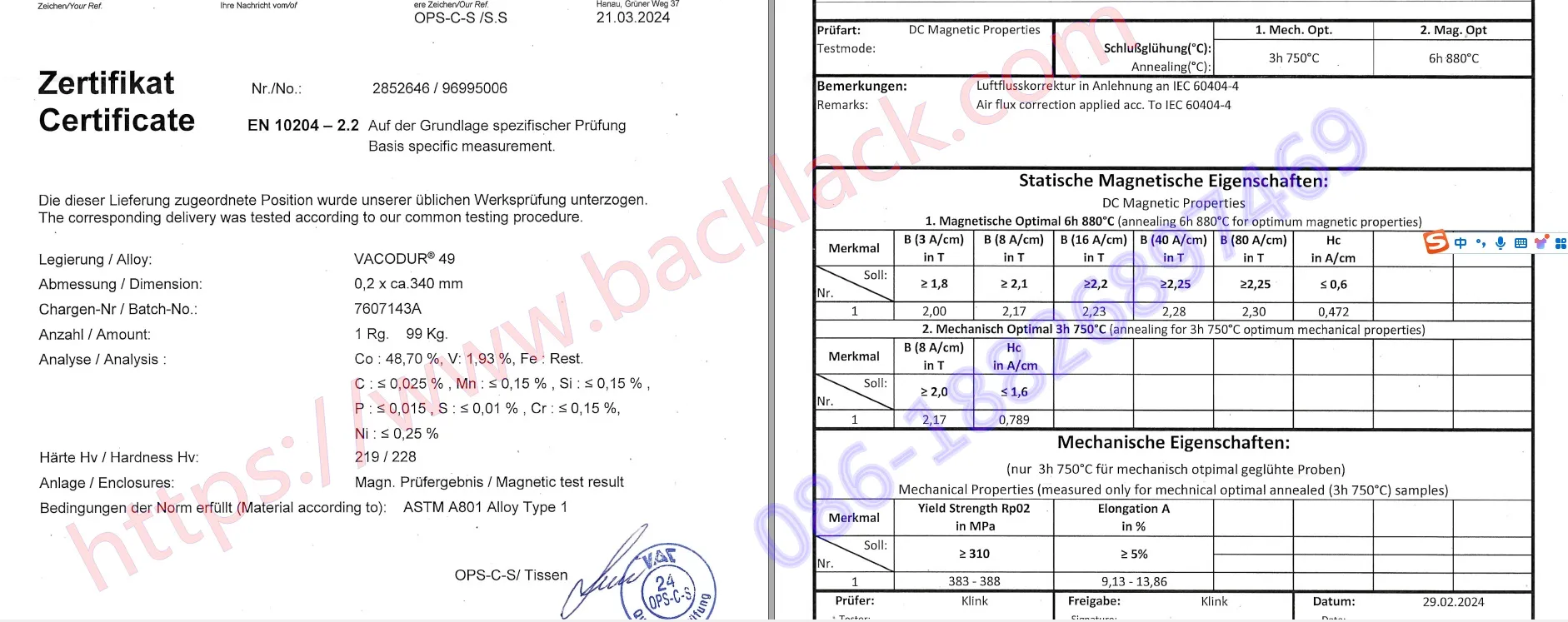

VACODUR® 49—developed by Vacuumschmelze (VAC) and compliant with ASTM A801-09 Alloy Type 1 and IEC 60404-8-6 F11 standards—is a cobalt-iron-vanadium alloy (49% Co, 2% V, balanced Fe with Nb additions) designed to outperform standard silicon steel in the most rigorous electric motor environments. Its unique properties make it unmatched for lamination stacks that require both magnetic excellence and mechanical durability:

- Exceptional Magnetic Saturation: With a saturation polarization of up to 2.30 T (and 2.35 T at 40 kA/m), VACODUR® 49 enables higher flux density in motor cores. This means smaller, lighter lamination stacks can deliver the same or higher power output—critical for compact, high-power-density motors in EVs, aviation, and portable industrial equipment.

- Adjustable Mechanical Strength: A key advantage of VACODUR® 49 is its tunable yield strength, ranging from 210 MPa to 400 MPa through controlled heat treatment. This allows us to optimize stator and rotor laminations from the same sheet: stator laminations are heat-treated for magnetic performance, while rotor laminations get a mechanical optimization to handle high rotational speeds (up to 50,000 RPM in some applications).

- Low Core Losses: Even at high frequencies (up to 1000 Hz), VACODUR® 49 maintains low specific iron losses. For a 0.35 mm thick sheet at 1.5 T and 50 Hz, losses are as low as 1.6 W/kg (magnetically optimized), minimizing energy waste and improving motor efficiency.

- High Thermal Stability: With a Curie temperature of 950 °C, VACODUR® 49 retains its magnetic properties even in high-temperature motor environments, ensuring long-term reliability in harsh operating conditions.

To better illustrate VACODUR® 49’s advantages, we’ve compiled a direct comparison with standard non-oriented silicon steel (3% Si)—the most common material for conventional motor laminations. This table highlights why VACODUR® 49 is the superior choice for high-performance, high-efficiency electric motor applications:

| Key Performance Metric | VACODUR® 49 Sheet Material | Standard Non-Oriented Silicon Steel (3% Si) | VACODUR® 49 Advantage |

|---|---|---|---|

| Magnetic Saturation Polarization | Up to 2.30 T (2.35 T at 40 kA/m) | ~1.70 T | 35% higher flux density for smaller, more powerful cores |

| Specific Iron Loss (0.35 mm, 1.5 T, 50 Hz) | 1.6 W/kg (magnetically optimized) | ~4.0 W/kg | 60% lower core losses, boosting motor efficiency |

| Yield Strength (Tunable via Heat Treatment) | 210–400 MPa | 180–250 MPa | 60% higher maximum strength for high-RPM rotors |

| Curie Temperature | 950 °C | ~750 °C | 27% higher thermal stability for harsh environments |

| Maximum Operating Frequency | Up to 1000 Hz | Up to 500 Hz | Doubles frequency capability for high-speed motors |

| Typical Application | EV powertrains, aviation motors, high-speed generators | Conventional industrial motors, low-efficiency appliances | Ideal for next-gen high-performance motor designs |

Compared to standard silicon steel—long the workhorse of conventional motor laminations—VACODUR® 49 eliminates the trade-off between power density and efficiency. For manufacturers focused on high-efficiency electric motors and lightweight motor designs, this translates to smaller, more reliable motors that reduce energy consumption and operational costs—making VACODUR® 49 the go-to material for next-generation motor cores.

For manufacturers focused on high-efficiency electric motors and lightweight motor designs, VACODUR® 49 sheet material eliminates the trade-off between power and size—making it the go-to material for next-generation motor cores.

Our Custom Process: Turning VACODUR® 49 Sheet Material Into Precision Lamination Stacks

Processing VACODUR® 49 sheet material requires specialized expertise and equipment—something our factory has refined over years of custom motor core manufacturing. We follow a rigorous, tailored process to ensure every lamination stack preserves VACODUR® 49’s exceptional properties and meets your motor’s unique requirements:

-

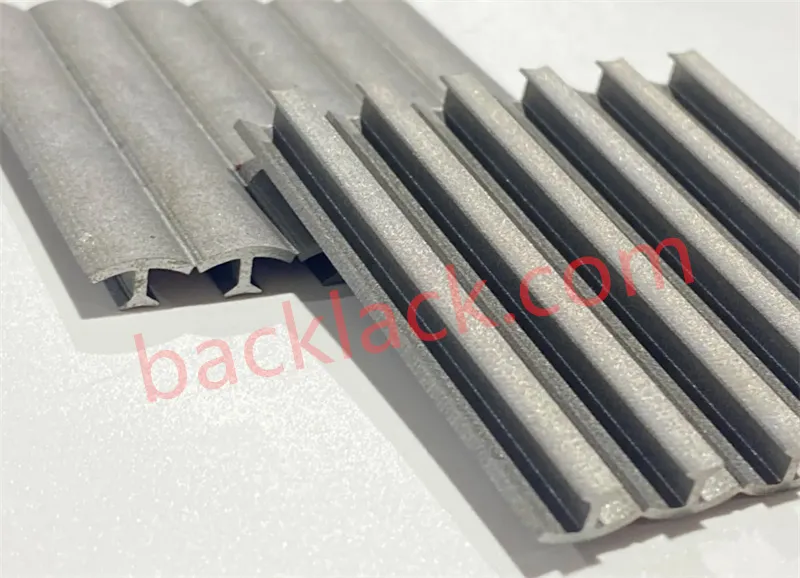

Premium Material Sourcing & Preparation

We source authentic VACODUR® 49 sheet material in strip form (thickness: 0.05–1 mm, width: 120–320 mm) to guarantee consistent quality. Before processing, we inspect each sheet for surface defects, thickness uniformity, and chemical composition—ensuring it meets VAC’s strict standards for cobalt-iron alloys. This step is critical to avoiding core losses caused by material inconsistencies.

-

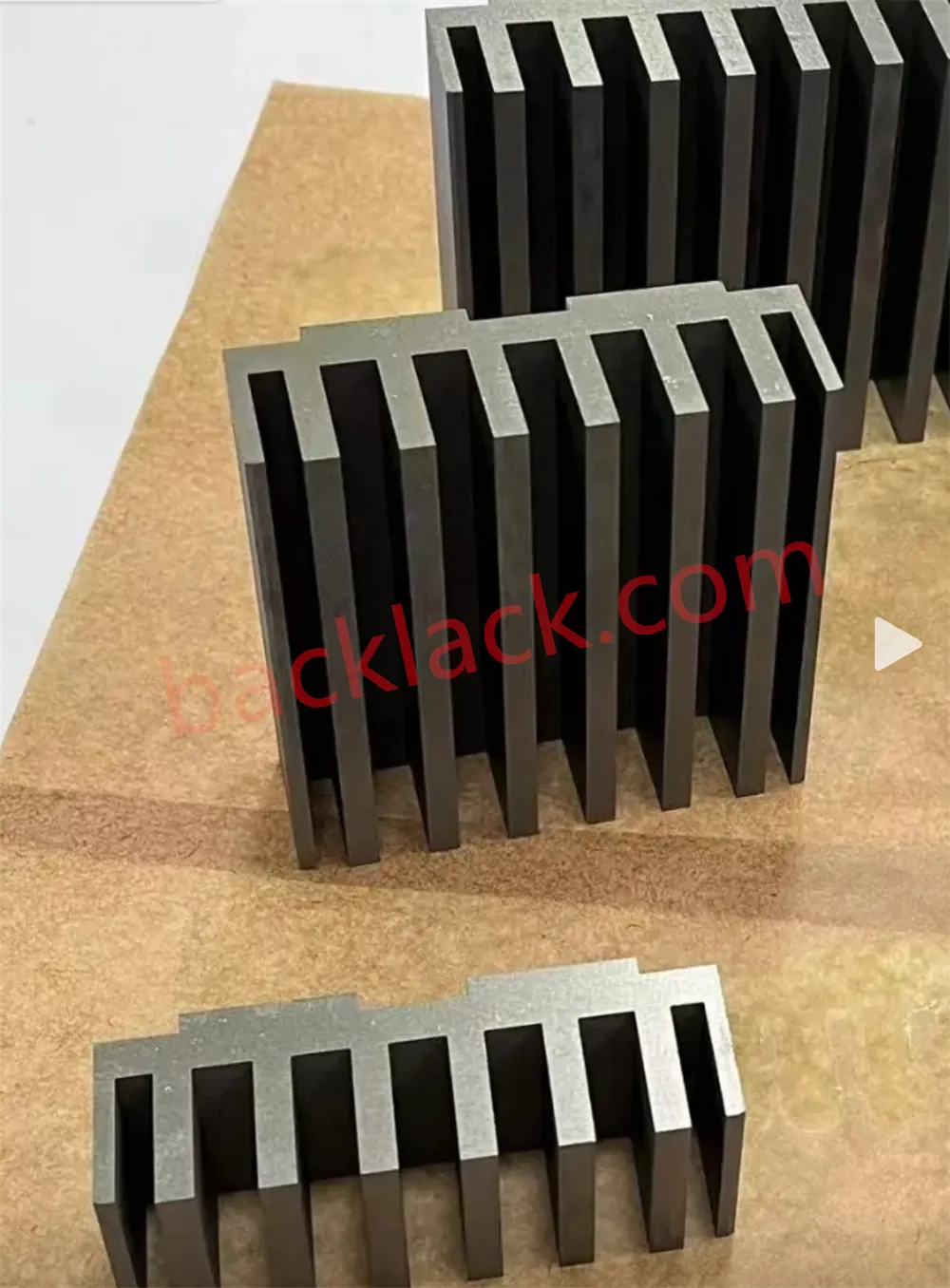

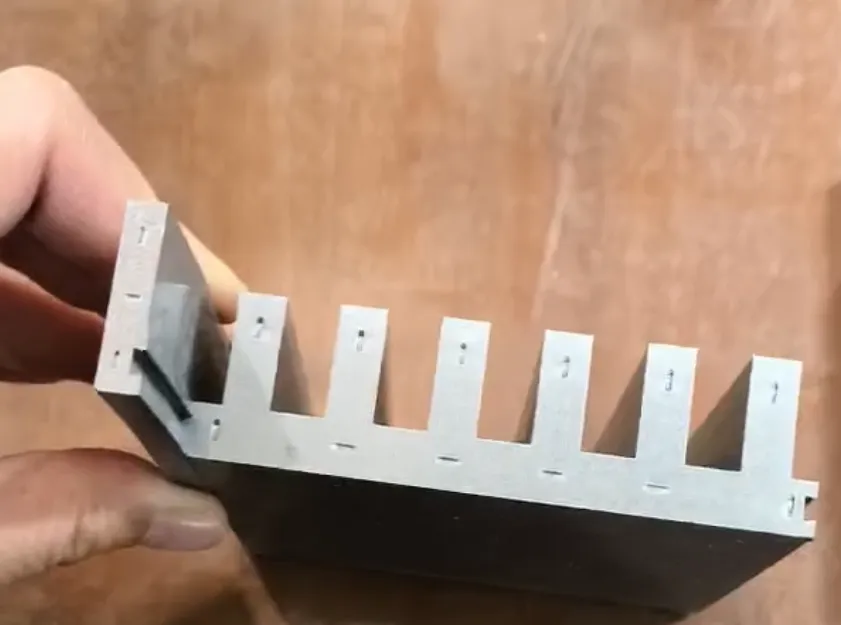

Precision Stamping

Using high-precision stamping equipment, we cut VACODUR® 49 sheets into individual laminations (stator and rotor cores) based on your custom CAD designs. Our stamping process minimizes material waste and maintains tight dimensional tolerances—critical for lamination alignment and motor efficiency. For optimal material utilization, we can stamp stator and rotor laminations in a single process, reducing costs for high-volume orders.

-

Tailored Heat Treatment

Heat treatment is the key to unlocking VACODUR® 49’s dual magnetic and mechanical potential. We use specialized annealing processes in a dry hydrogen atmosphere to optimize each lamination type:

Magnetically Optimized Laminations (Stators): Annealed at 880 °C for 6 hours to minimize coercivity (down to 50 A/m) and maximize permeability (up to 18,000 µmax).

Mechanically Optimized Laminations (Rotors): Annealed at 750 °C for 3 hours to boost yield strength (up to 390 MPa) for high-speed rotation resistance.

-

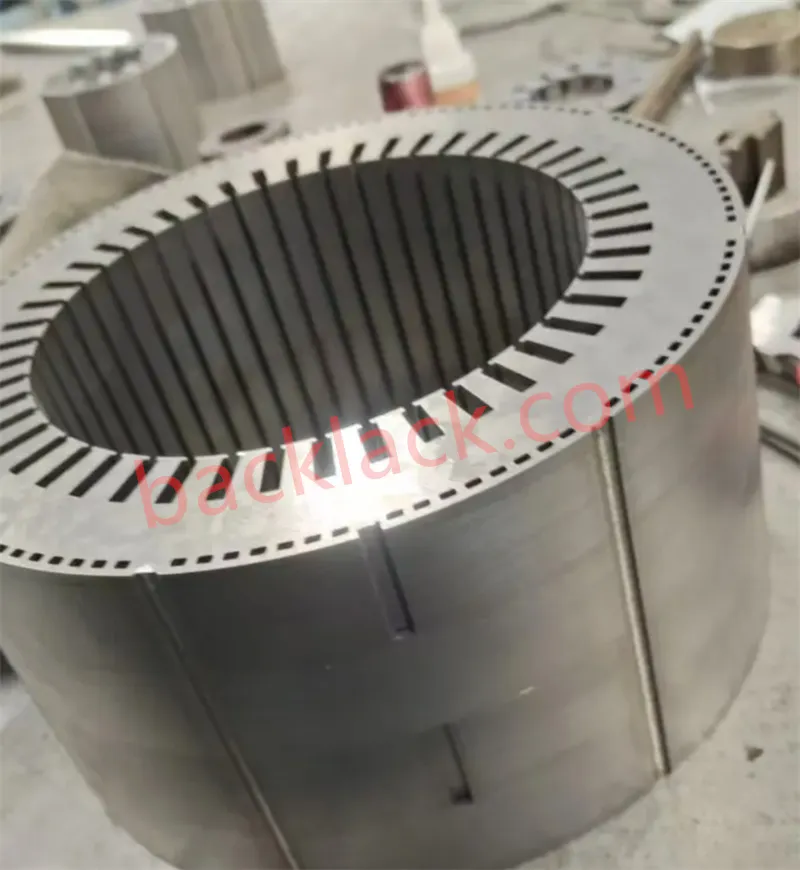

Lamination Stacking & Bonding

We stack the precision-stamped, heat-treated laminations with tight alignment to ensure a fill factor of up to 98%—reducing eddy current losses and improving magnetic flux transfer. For bonding, we use laser tying (a scalable, cost-effective process for high-volume orders) or adhesive bonding, depending on your motor’s requirements. Laser tying creates internal joints that enhance stack cohesion while reducing the number of tying points compared to traditional punching.

-

Quality Control & Testing

Every VACODUR® 49 lamination stack undergoes rigorous testing before delivery: magnetic performance (flux density, core loss), dimensional accuracy, stack height, and mechanical strength. We also conduct visual inspections to ensure no lamination damage or misalignment—guaranteeing your stack integrates seamlessly into your electric motor assembly.

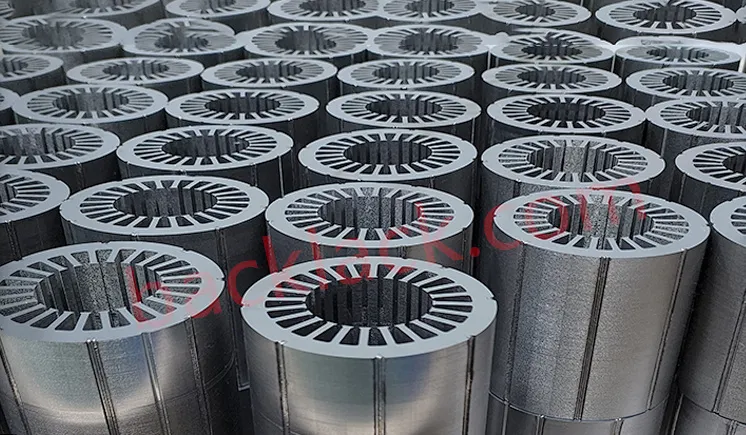

Applications: VACODUR® 49 Lamination Stacks for High-Performance Electric Motors

Our custom VACODUR® 49 lamination stacks are trusted by electric motor manufacturers across industries that demand the highest performance. Key applications include:

High-Speed Electric Motors & Generators

Ideal for synchronous reluctance machines and other designs operating at 5,000–50,000 RPM, where mechanical strength and low core losses are critical.

Automotive Electric Drives

EV and HEV powertrains benefit from VACODUR® 49’s high power density and lightweight design, improving range and efficiency.

Aviation & Aerospace Motors

The alloy’s thermal stability and reliability make it perfect for aircraft and spacecraft motor systems.

Industrial High-Efficiency Motors

Motors for pumps, compressors, and manufacturing equipment, where reduced energy losses translate to lower operational costs.

Why Choose Our Factory for Your VACODUR® 49 Lamination Stack Needs?

As a specialized motor core custom processing factory, we don’t just process VACODUR® 49 sheet material—we partner with you to optimize your lamination stack design for performance, cost, and scalability. Unlike factories that only handle standard silicon steel, our expertise in cobalt-iron alloy processing ensures we preserve VACODUR® 49’s unique properties through every step. Here’s what sets us apart:

- Expertise in VACODUR® 49: We understand the unique processing requirements of this premium cobalt-iron alloy, from stamping to heat treatment, to preserve its magnetic and mechanical properties.

- 100% Customization: Every lamination stack is tailored to your motor’s CAD designs, performance goals, and volume needs—no one-size-fits-all solutions.

- Quality Assurance: Strict material inspection and post-processing testing ensure every stack meets VACODUR® 49’s specifications and your motor’s requirements.

- Scalability: Our laser tying and high-precision stamping processes support both low-volume prototypes and high-volume production runs, with consistent quality at every scale.

Looking for a manufacturing partner?

If you’re designing a high-performance electric motor and need VACODUR® 49 sheet material transformed into precision lamination stacks, we’re here to help. Our team of engineers will work with you to refine your design, optimize processing, and deliver a stack that unlocks the full potential of VACODUR® 49—boosting your motor’s efficiency, power density, and reliability.

Request a Technical ConsultationContact us now to discuss your project: share your motor specifications, CAD designs, and volume needs, and we’ll provide a tailored quote and timeline for your custom VACODUR® 49 lamination stacks. Let’s build the next generation of high-efficiency electric motors—together.

About Youyou Technology

Youyou Technology Co., Ltd. specializes in the manufacture of Self-bonding precision cores made of various soft magnetic materials, including Self-bonding silicon steel, ultra-thin silicon steel, and Self-bonding specialty soft magnetic alloys. We utilize advanced manufacturing processes for precision magnetic components, providing advanced solutions for soft magnetic cores used in key power components such as high-performance motors, high-speed motors, medium-frequency transformers, and reactors.

The company Self-bonding precision core products currently include a range of silicon steel cores with strip thicknesses of 0.05mm(ST-050), 0.1mm(10JNEX900/ST-100), 0.15mm, 0.2mm(20JNEH1200/20HX1200/ B20AV1200/20CS1200HF), and 0.35mm(35JNE210/35JNE230/ B35A250-Z/35CS230HF), as well as specialty soft magnetic alloy cores including Hiperco 50 and VACODUR 49 and 1J22 and 1J50.