The Tragedy of Traditional Processes: Why Change Is Needed?

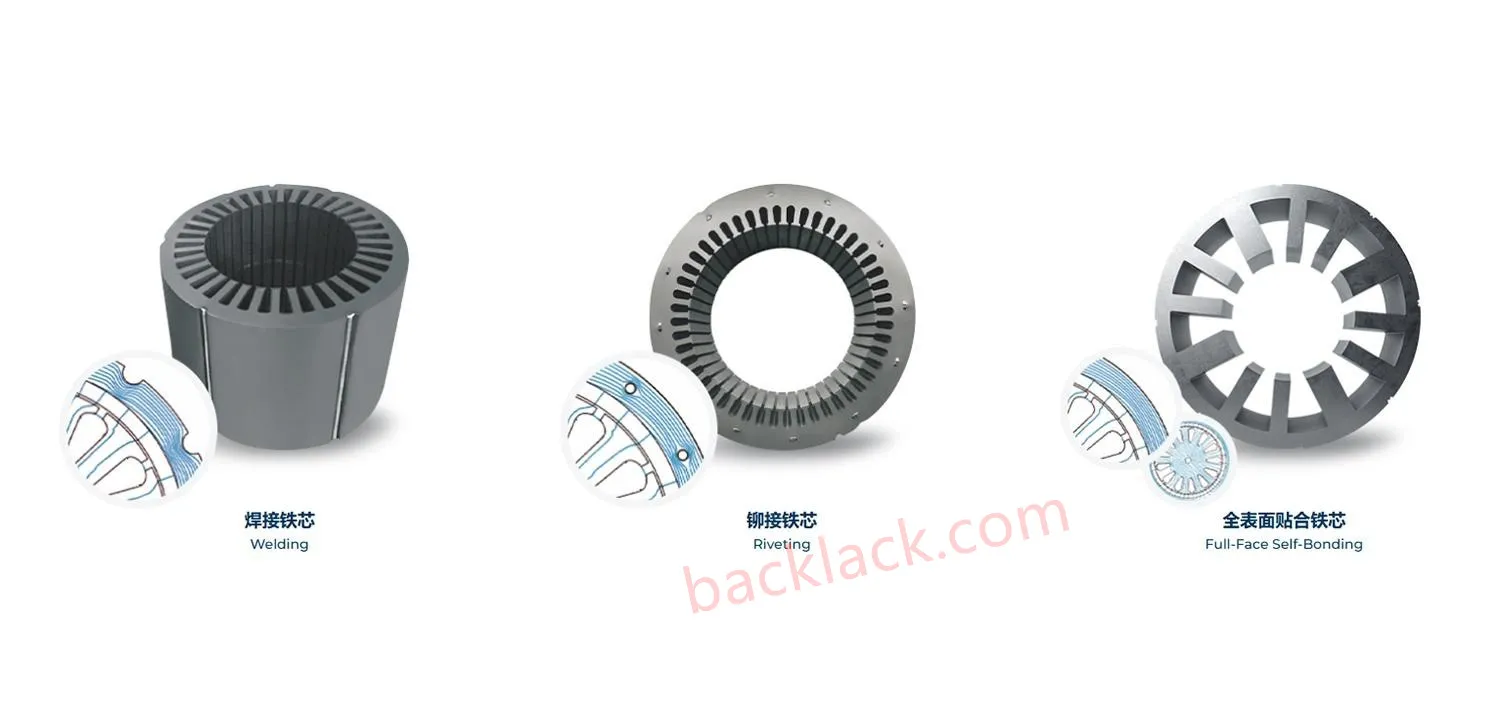

Traditional motor stator and rotor core manufacturing relies on mechanical methods (such as riveting, welding, and clipping) to stack and secure stamped silicon steel sheets. This decades-old, mature method presents numerous inherent pain points:

-

Efficiency Loss

Riveted and welded points can create local short circuits in the core, generating additional eddy current losses and reducing motor efficiency, especially in high-speed, high-frequency applications.

-

Mechanical Stress

The riveting and welding processes introduce mechanical and thermal stresses, which degrade the magnetic properties of the silicon steel sheets and increase iron losses.

-

Vibration and Noise

Tiny gaps between sheets can easily generate vibration and noise under the influence of electromagnetic forces, impacting the motor's NVH (noise, vibration, and harshness) performance.

-

Design Limitations

Mechanical fixing points occupy valuable space, limiting further increases in slot fill rate and power density.

-

Environmental and Safety

Welding generates fumes and riveting produces metal debris, posing challenges to the production environment and worker health.

Backlack Technology: An Elegant Solution

backlack technology has emerged, solving all of the aforementioned problems in an elegant way. Its core involves coating the surface of the silicon steel sheets with a special bonding varnish. After the sheets are stamped and stacked, the varnish is cured by heat and pressure, firmly bonding all the sheets together into a solid, integrated core.

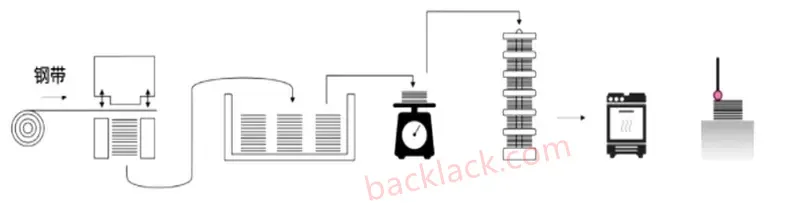

The simplified process flow is:

Silicon steel coil → bonding varnish coating → Drying (to a semi-cured state) → Precision stamping → Lamination → Heat and pressure curing → Forming a high-strength, integrated core

Why is it called a "Game Changer"? Four Core Advantages

-

Significantly improves motor efficiency

Eliminates local short circuits: No rivets or welds, completely eliminating eddy current losses caused by mechanical fastening, reducing iron loss by 10%-20%.

Reduces iron loss: Prevents processing stress from damaging the magnetic properties of the silicon steel sheets, maintaining the material's optimal performance.

-

Achieves excellent NVH performance

100% surface contact: The adhesive layer fills all microscopic gaps between the sheets, forming an extremely rigid overall structure, significantly suppressing vibration and audible noise, and providing a quieter experience for high-end applications such as electric vehicles, precision medical devices, and home appliances.

-

Unlocks higher power density

Space savings: Eliminating the space occupied by rivets allows for deeper slots or thinner yokes, allowing for the insertion of more copper wire, increasing torque and power output, and achieving smaller and lighter motors.

-

Enhanced reliability and simplified production

Corrosion and moisture resistance: The adhesive layer effectively isolates moisture, protecting the core from corrosion and extending motor life.

Automated production: This technology is perfectly suited for fully automated punching, stacking, and riveting production lines, reducing production steps and improving consistency, making it an ideal choice for implementing Industry 4.0 smart manufacturing.

Application Prospects: Who Will Benefit First?

Adhesive backlack technology isn't a panacea, but its advantages are crucial in specific areas:

- Electric vehicle drive motors: These require extremely high efficiency, power density, and noise levels, making them a core application area for adhesive backing technology.

- Precision servo motors and robotics: They demand low loss, high response, and low vibration, and adhesive backing cores offer unparalleled performance advantages.

- High-end home appliances and drones: They strive for quiet operation and long-term durability, and adhesive backing technology is the secret weapon to elevate product quality.

- High-speed motors: Traditional fixing methods can loosen at high speeds, while the integrated structure of adhesive backing provides irreplaceable reliability.

Looking Ahead: Embracing Technological Change

Backlack technology represents the inevitable trend toward more efficient, sophisticated, and integrated motor design. With the continuous advancement of bonding varnish materials (e.g., higher bond strength, improved insulation, and lower curing temperatures), its cost will further decrease, and its application will gradually expand from the high-end market.

For motor manufacturers, early deployment and mastery of backlack technology means seizing the initiative in the upcoming fierce competition and gaining a voice in defining the next generation of high-performance motors.

Conclusion

Technological advancements always simplify. backlack technology replaces bulky rivets and hot solder joints with a thin layer of varnish, not only resolving long-standing engineering challenges but also opening up new horizons in motor design. This represents not only an upgrade in technology but also a revolution in thinking. Are you ready?

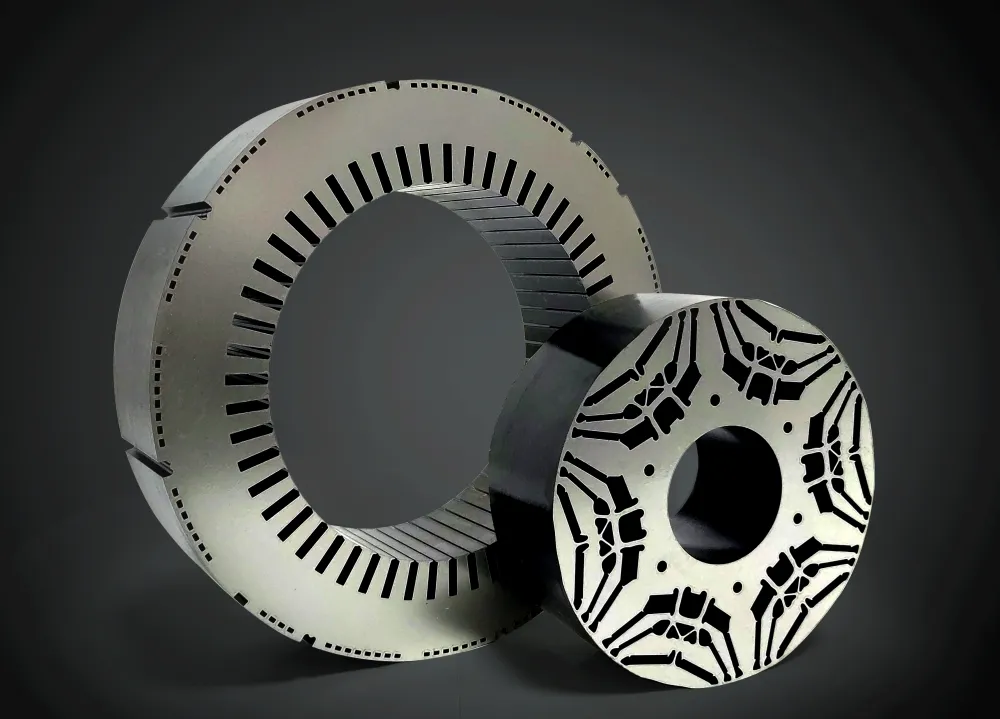

About Youyou Technology

Youyou Technology Co., Ltd. specializes in the manufacture of backlack precision cores made of various soft magnetic materials, including backlack silicon steel, ultra-thin silicon steel, and backlack specialty soft magnetic alloys. We utilize advanced manufacturing processes for precision magnetic components, providing advanced solutions for soft magnetic cores used in key power components such as high-performance motors, high-speed motors, medium-frequency transformers, and reactors.

The company Self-bonding precision core products currently include a range of silicon steel cores with strip thicknesses of 0.05mm(ST-050), 0.1mm(10JNEX900/ST-100), 0.15mm, 0.2mm(20JNEH1200/20HX1200/ B20AV1200/20CS1200HF), and 0.35mm(35JNE210/35JNE230/ B35A250-Z/35CS230HF), as well as specialty soft magnetic alloy cores including Soft Magnetic Alloy 1J22/1J50/1J79.